REVIEW – Over the last few years I have become quite a fan of the xTool laser engraver and cutting machines. The latest offering from xTool is the S1 Laser Engraver and Cutter, and it certainly has quite a few features that are amazing. However, the xTool S1 is missing one thing that the xTool M1 engraver and xTool P2 laser engravers have. Will that one thing be a deal breaker? Read on to find out.

What is it?

The xTool S1 is the world’s first 40W enclosed diode laser cutter/engraver that features quick-change laser modules in a quiet, compact, and capable format.

What’s in the box?

- xTool S1 Laser Engraver and Cutter

- 40W Laser Module (10W and 20W versions also available)

- Instruction Book

- Power adapter

- Hex Driver

- Spare lens covers (2)

- Exhaust Hose

Also Reviewed:

- Air Assist Accessory

- Riser Base and Honeycomb Accessory

- 2W Infrared Laser Module

Hardware specs

- The first Class-1 safety certification enclosed 40W diode laser machine, it’s eye-friendly and you can run it without wearing protective goggles

- Power: 20W, 40W, 2W IR

- Spot Size: 40W: 0.10×0.15mm, 20W: 0.08×0.10mm

- Working area: 40W: 498*319mm, 20W: 498*330mm

- Speed: 600mm/s

- Connection: Wi-Fi/USB

- Software Support: Phone: Android & iOS, Tablet: iPad, Computer: Windows & macOS

- Software: XCS/Lightburn

- Interchangeable laser modules

- Stable performance at 600mm/s

- Product size 765 * 561 * 183mm (excluding riser base), 765 * 561 * 268mm (including riser base)

- Real-time laser module positioning

- Material area measurement

- Curved surface mode

- 5-direction flame detection

Design and features

I like xTool products, but I’m not a blind follower. There have been a few things with each machine that I would have liked to have been different, but overall I have been very happy with them. When xTool offered to send their new S1 Laser Engraver and Cutter for me to review, I was more than happy to say yes. Okay, I’ll admit that I was absolutely giddy. The world’s first 40W enclosed diode laser cutter? Oh Yes!

I have turned down reviews from other laser companies, mostly because I either didn’t like the machine specifications, or I could not see a good real-world use for them in my daily activities. I like to use the machines I review in real use cases, such as creating items in a production setting.

The xTool S1 arrived very well packaged. When I took on the review, the only thing I knew about the machine was that it had a 40W diode laser module and a rough idea of what it looked like with an included photo. From the photo, it was hard to tell how big the machine was. I was ecstatic to find that it was larger than the xTool M1, yet had a smaller form factor than the xTool P2 while maintaining almost the same working area. It’s a beautiful design with a partially open front when the cover is open.

I was pleasantly surprised that xTool also sent along the optional 2W IR (1064nm) laser module accessory. This highlights the first great feature of this machine – easily interchangeable laser modules. Not only can you change the laser module, but it is very easy to do so.

To change the laser module, you only have to unplug the air assist hose and the electrical connector, and then remove two screws that are easily accessed on the top of the laser module. The magnetically attached distance probe can then be moved to the new laser module.

The 40W laser module features eight 6W lasers that are combined to achieve a 40W output capable of cutting efficiency comparable to CO2 machines. The S1 is capable of cutting up to 18mm of solid wood (almost 3/4″).

As I was inspecting and checking out the S1’s construction I was baffled, I could not find the camera. As it turns out, the xTool S1 does not have a camera like the M1 and P2. At first, I was quite disappointed, as all of my lasers have always had a camera. However, once I ran the XCS software, it all made sense. More on that later.

As I continued to inspect and set up the S1, I noticed that the exhaust port was quite different than previous xTool lasers. Instead of a simple 3-inch exhaust flange that you attach a flexible hose to, the S1 implements a 57″ (14.5cm) semi-rigid hose that is permanently mounted in the removable exhaust port flange.

Although the inside diameter of the hose is 3 inches, it’s fairly stiff. I’m not sure how easily this will connect/clamp to other 3-inch exhaust vent systems. One good thing is that the mounting face of the exhaust port has a rubber-like coating to ensure a good seal. However, there are always 3rd party exhaust solutions to be found.

xTool also sent me the Riser Base and Honeycomb accessory. I was very happy to see this as I use the rotary accessory quite a bit. The all-metal riser base attaches to the laser with screws, unlike their other machines that just sit on the riser base. The Riser base is about 4.2″ (106mm) tall, which is a bit less than their other laser riser bases. Another nice feature is that the Riser base assembles with just four screws. The Riser Base also increases the S1’s ability to engrave objects up to 125mm tall.

The honeycomb is the same design as the other xTool lasers, however, the S1 honeycomb comes with the new style of magnetic hold-down pins. I found these to be very nice. The little wire clip makes them much easier to install and remove. The honeycomb does not sit on any rail surface, but instead just sits in the crumb tray, so you’ll have to be careful that it is positioned where you want when doing repeated work.

Unlike the xTool M1 and P2, the S1’s laser module can be moved manually even when the laser is powered on. With the real-time laser module positioning, the XCS software/laser knows where the laser head is at all times, and even projects a “+” crosshair symbol at its position on the design screen. The laser module has a sort of framing laser crosshair that projects down onto the work material, even when the lid is open. This is used to position the laser.

I previously mentioned the lack of a camera. This is where the S1’s material area measurement feature comes in. There’s a “Start marking” button on the right side of the software. When clicked, a dialog box is displayed with instructions. Basically, you can manually move the laser to the upper left corner of your material, then press the button on the front of the machine. Next, you move the laser to the lower right corner of your material, then press the button on the front of the machine again. Returning to the software and dismissing the dialog box will produce a green rectangle on the design grid. You can then place your design in the rectangle.

For many uses, like cutting items from a fresh sheet of material, this is actually very easy and accurate. However, for other uses where you might be engraving on an odd-shaped item, it may require you to take some measurements.

For users who like to use jigs, the marking feature is very nice. Just line up the laser position indicator with the corner of your jig, move your design to align, and start the engraving or cutting process. The jig could even be in a different spot each time.

The xTool S1 also implements a new distance-measuring probe. Since the S1 doesn’t have a camera to measure the material, a mechanical probe magnetically attaches to the side of the laser module (so it can be moved when the module is changed). When needed, the software drops the probe down, lowers the laser module until the probe touches the material, and then moves to the rear corner to reset the probe.

The S1 continued to surprise me. The built-in air assist tubing was a very welcome feature to find. The new Smart Air Assist pump accessory is external and features a knob for control. The knob settings are: Auto, Off, 1, 2, 3, and Max. The Auto setting is controlled by the XCS software. Not having to remember to turn on the air assist is a great feature!

However, when I went to connect the Air Assist, I could not find an included power adapter and cord. That’s when I found out that there wasn’t one. The S1’s air assist is powered and controlled via a small cable that connects to the S1. The cable looks very similar to a USB Type-C cable, but it isn’t. The part that threw me off was that there is a power connector on the new air assist unit, but I’m guessing that is probably for other lasers that don’t have the power delivery capability of the S1.

Continuing to explore the S1, I found two internal LED strips that provide excellent lighting inside the machine. The front LED strip is 26″ long, and the rear is 23″. Previously, lighting inside the machines was one of the things I didn’t like, but the S1 excels at this.

The xTool S1 also has the ability to connect a conveyor accessory. xTool did not send one with the unit, so it might not be available yet. The conveyor accessory will enable the engraving and cutting of longer material, as it mechanically feeds the material through the machine, passing it out of the back of the machine.

Like all of the other xTool lasers, the S1 is compatible with xTool’s RA2 Pro Rotary. The rotary is used to engrave cylindrical items like balls, tumblers, rings, and glasses.

When it comes to software, the xTool S1 can be used with the free xTool Creative Space (XCS) or Lightburn. I tested only with XCS as it does everything I need, and Lightburn is a paid program. Also, real-time laser module positioning, material area measurement, and curved surface mode are not supported by LightBurn.

Four-tier safety protection

The xTool S1 also features a 5-direction flame detection which uses four baffles and a laser module to detect flames. The Lid-open safety stop triggers an emergency stop upon cover opening, preventing laser leaks. The Tilt and impact detection function automatically halts and alerts when the unit is disturbed, guaranteeing safe operation. There is also an Emergency stop switch conveniently placed on the side which allows for immediate process cessation, safeguarding the operator.

Dynamic-focus engraving

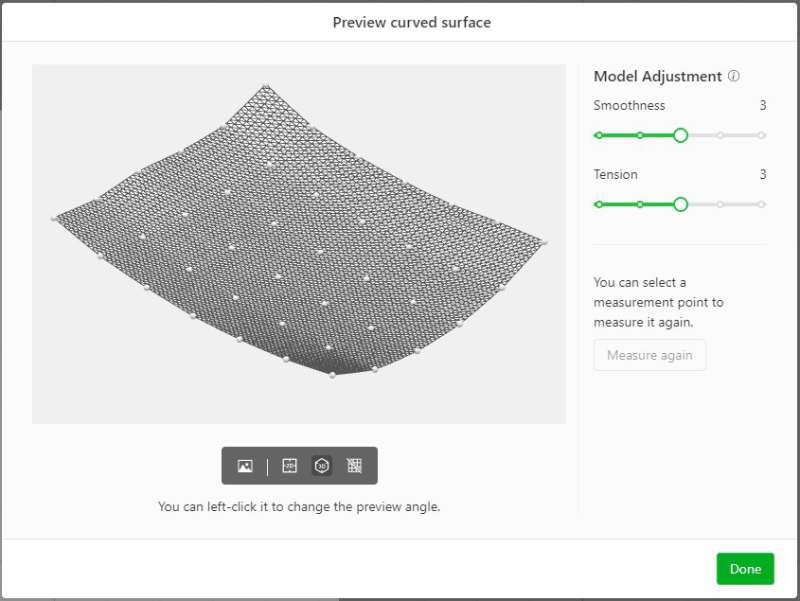

The S1 can also perform curved surface engraving like the P2. With its advanced Intelligent Focus System, the S1 can 3D map a curved surface and the motorized Z-axis dynamically adjusts the focus in real-time during processing, achieving an engraving effect as flawless as that on a flat surface. By designating an upper left and lower right corner of the area you wish to engrave, the S1 can map the curved surface and generate a 3D model of the surface. The software will then adjust the height (focus distance) of the laser as it engraves.

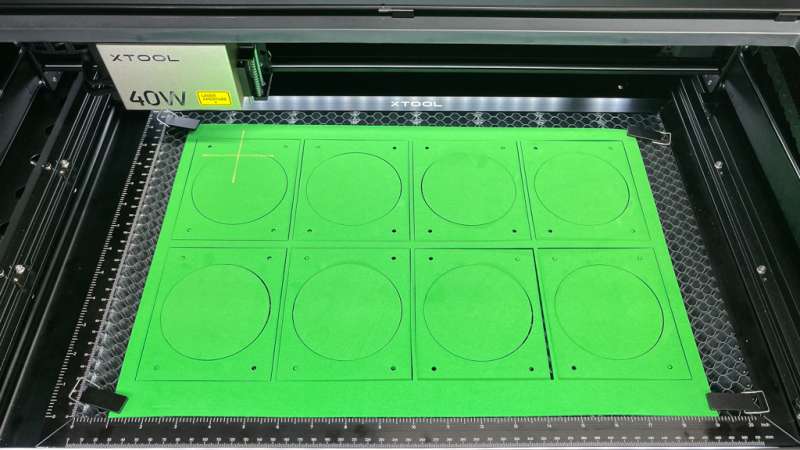

One of the first things I did was to convert items that I cut frequently in the xTool M1 to cut in the S1. The S1 provides twice the capacity of the M1 for me. In the M1, I was cutting 12″x18″ sheets of foam in half to be able cut items out of them. In the S1, I can place the entire 12″x18″ sheet of EVA foam in the laser. This saves me time in both cutting the sheets with scissors and with the increased speed of the S1. On the M1 I was cutting at 100% power at 70mm/s, and on the S1 I can cut at 80% power at 200mm/s.

When cutting 3mm MDF, I found that I could cut at 13mm/s vs 4mm/s on the 10W M1. That’s about 3.5 times faster than the M1, plus the charred edge of the MDF had much less soot, which didn’t rub off onto my hands like it did on the M1.

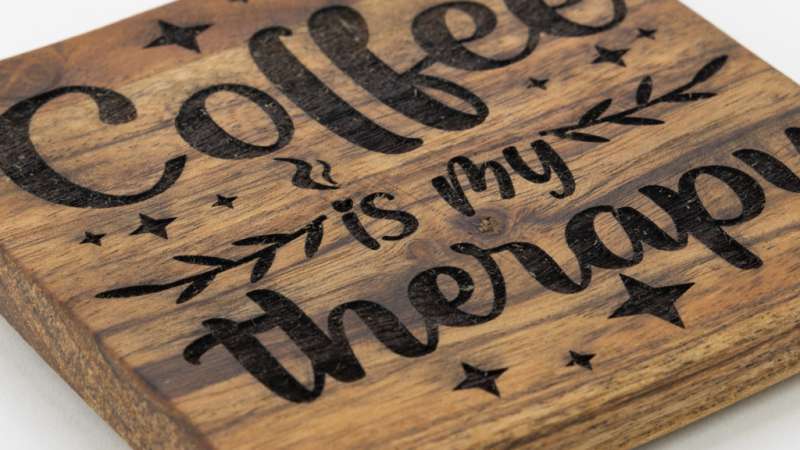

My brother sells wood pallets as a side hustle, so I made him a coaster from 3mm basswood plywood.

One of the things I really like about the xTool S1 is the ability to run the framing test with the lid open. Since the framing uses a low-power laser crosshair, it’s safe to frame with the lid open. This allows you to reposition your item and press the button to check the framing without opening/closing the lid, or having to restart the framing from the software. The crosshairs also make it easier to ensure that your material is square to the laser travel.

I achieved 0.5 to 1mm depth when engraving wood coasters. Not only was the engraving deep, but it was also very sharp and detailed, something that a diode laser excels at.

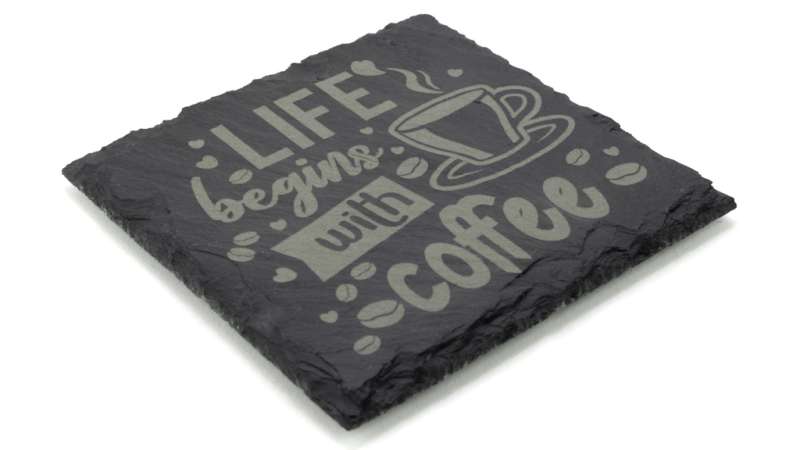

I engraved the sample slate coaster that came with the S1 at 90% power, 300mm/s, 1 pass, and 100 lines per cm. It came out fabulous, and only took 6.5 minutes! Previously, the M1 took so long that it was not reasonable for production work.

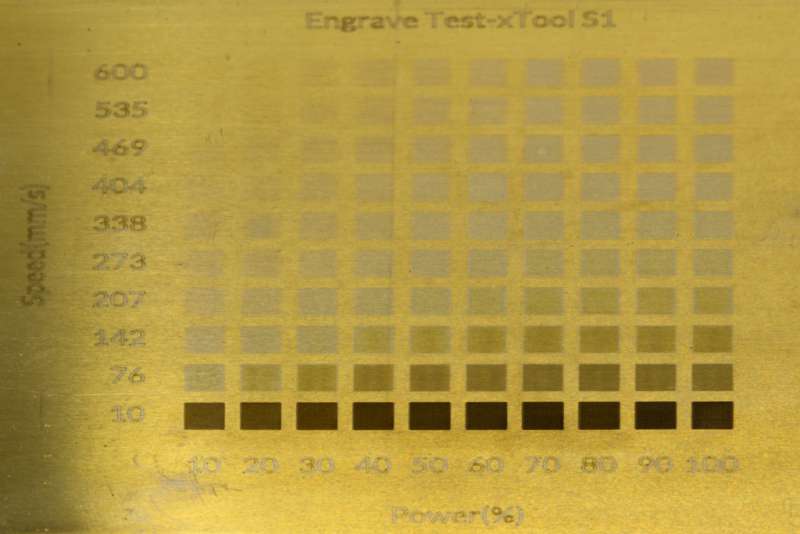

I made a test engraving on a piece of brass that I had lying around. The range of colors you can get with the 2W IR laser module is excellent. I plan to experiment with some multi-color metal engraving in the future.

What I like

- Quick change laser modules

- Software: XCS or Lightburn

- Framing with the lid open

- The laser module can be moved manually or via software to position the laser, the software/laser knows where the laser head is

- Smart Automatic Air Assist, powered by the machine. Not having to remember to turn on the air assistAccurate mechanical distance probe

- The machine is extremely quiet compared to the M1, P2, and Glowforge

- Great inside lighting

- Screwed on riser base

What I’d change

- It would be nice if the material area measurement feature could be triggered from the machine

Final thoughts

Overall, I really like the xTool S1. The speed is fabulous for what I do, and the machine is so much quieter than the M1, P2, and Glowforge. With all of the other machines that are going in my office all day long, the quiet operation of the S1 is a welcomed feature. For my production work, the lack of a camera did not affect my abilities, but it could be a factor for some people. xTool has really made some great improvements in this new laser.

Price: $2499.99

Where to buy: xTool

Source: The sample of this product was provided by xTool.

Gadgeteer Comment Policy - Please read before commenting

Have you tried with the auto conveyor feeder for the S1, and try if it can be integrated with the other laser cutters, even the OMTECH 60 WATTS.

There’s no shipping to Greece….i have tried to checkout payment but there is a message for invalid zip code….

Have you tried the EU site? https://www.xtool.eu/

Thanks for your review. I have a cnc set up already, and looking to move into laser. I been thinking what is best for me, the P2 or S1, and believe the S1 may work better for my wood working, since it would give me better engraving then the cnc, and faster. Thanks again for the review.