REVIEW – One of the more annoying things in 3D printing is when a print fails because of filament issues. You start a long print, check on it after a bit, and maybe notice some slight stringing; then, inevitably, you return later to find the horrid “bird’s nest,” strings, and gobs of costly filament everywhere. A lot of the time, these failures are due to the filament absorbing moisture, which is why every filament spool comes with packs of desiccant to help keep them dry. That’s why I wanted to try the Chitu Systems FilaPartner E1 Filament Dryer. I’ve had more than my share of failed prints, and even though many of them were due to operator error, I was hoping a filament dryer could help a bit. After several weeks of regular use, the E1 has definitely improved my success rate. Priced affordably at $139, the E1 is practical, well-built, and thoughtful in its design—even if it does have a few small quirks.

⬇︎ Jump to summary (pros/cons)

Price: $139

Where to buy: Chitu Systems and Amazon

What is it?

The Chitu Systems FilaPartner E1 Filament Dryer is an enclosed system that holds and heats up to four spools of 3D printing filament to maintain optimal printing conditions.

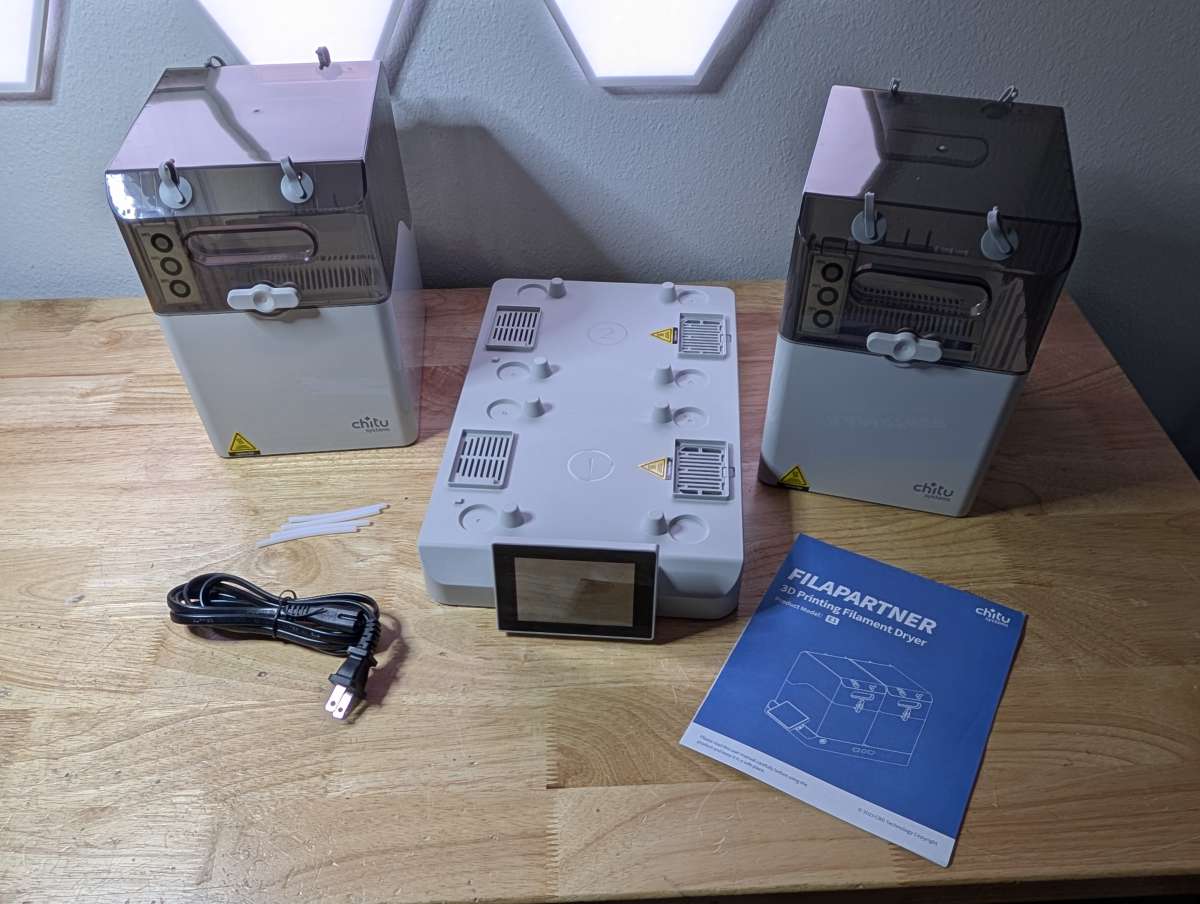

The E1 arrives in a standard cardboard box with a line illustration of the product on the front.

All components are safely packed in foam to prevent shipping damage.

What’s included?

- Chitu Systems FilaPartner E1 Filament Dryer base

- Filament boxes x 2

- Magnetic sealing plates x 4

- Filament feed tubes x 4

- Power cable

- Quick start guide

Tech specs

- Capacity: 4 spools total (2 spools per filament box)

- Independent temperature control for each box

- Temperature range: 35°F to 158°F (2°C to 70°C)

- Humidity monitoring in each box

- Touchscreen control panel with presets and timer

- Magnetic sealing plates for box covers

- Power: 110–240V AC, 50/60Hz

- Base dimensions: 12.6 x 9.8 x 5.1 in (320 x 250 x 130 mm)

- Box dimensions: 11 x 9 x 4.5 in (280 x 230 x 115 mm)

- Total weight: 8.6 lbs (3.9 kg)

Design and features

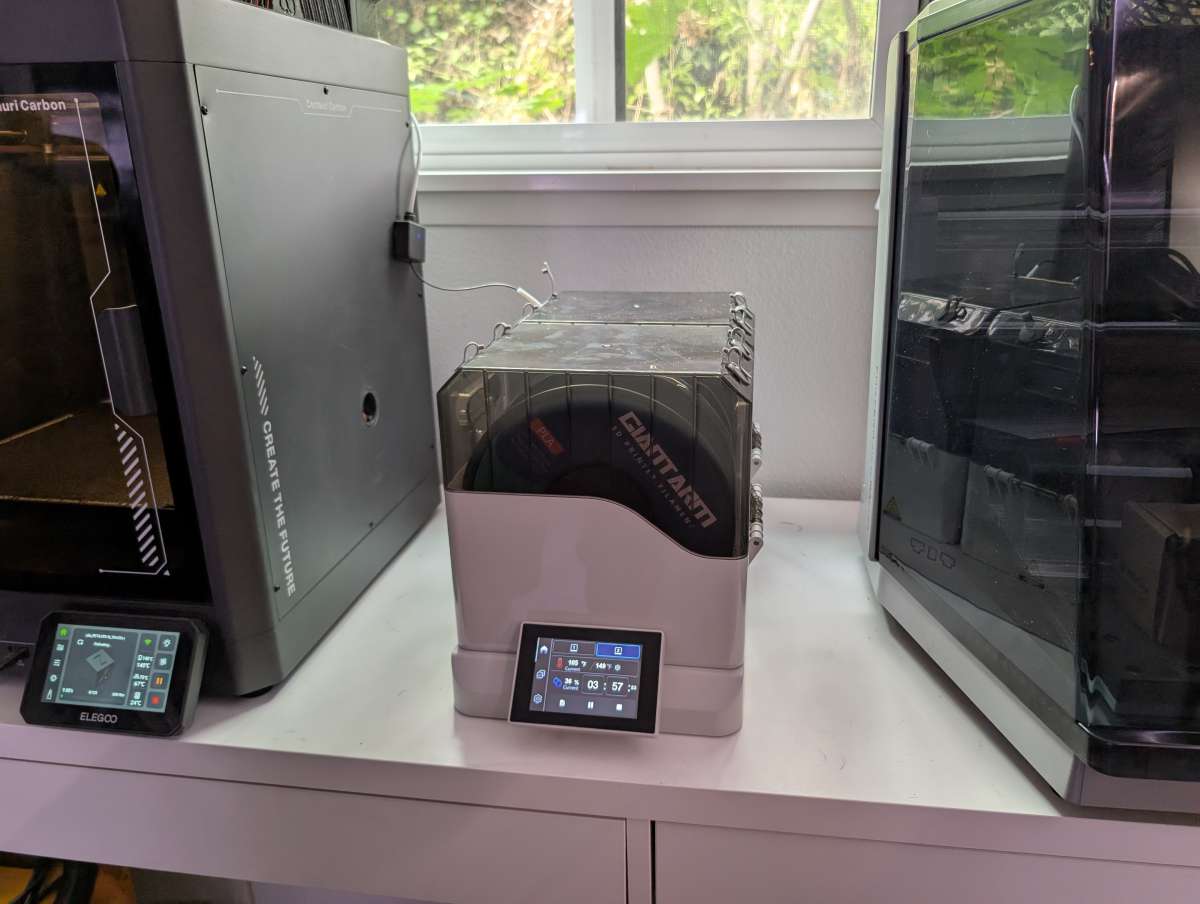

The E1 features a clean, practical design. The base houses the heating system and touchscreen, while the two filament boxes sit on top, with vents that channel heat into each.

The majority of the E1 is made of slightly textured, grey ABS plastic except for the lids of the filament boxes.

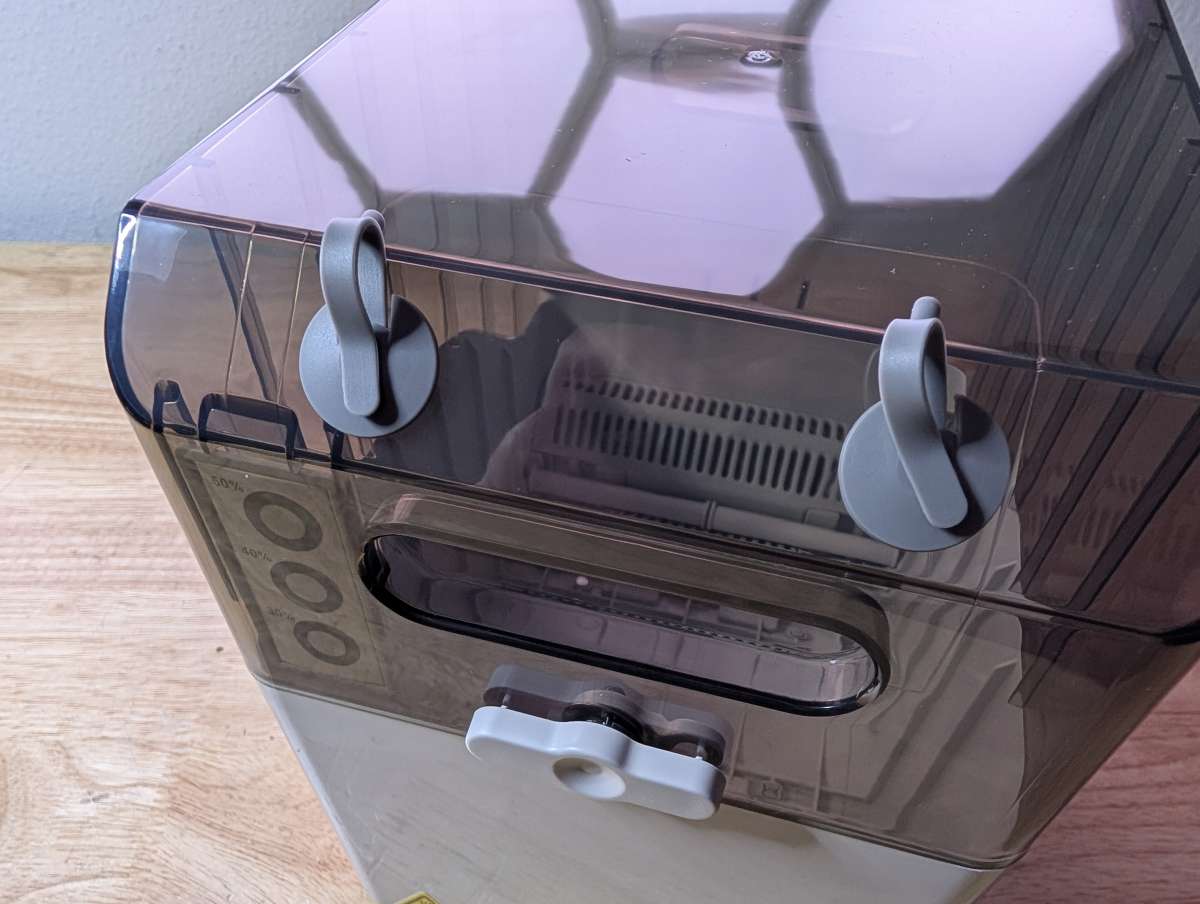

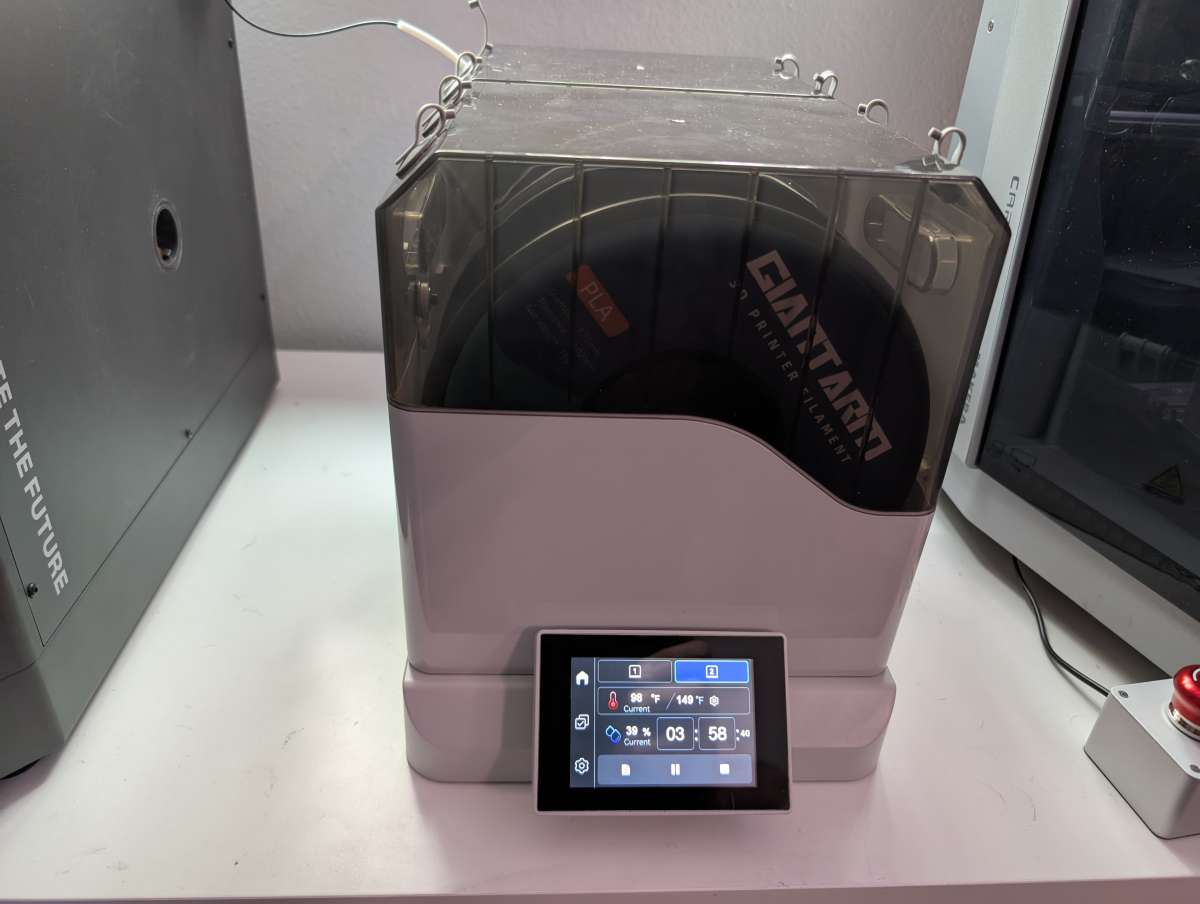

The lids are a clear tinted plastic, which should allow you to see the filament spools held inside, but unless your room is super bright, it’s kind of difficult to determine if the spools are running low.

Each filament box has four rubber filament ports, two on each side, along with a locking latch and a stick-on humidity indicator.

Four filament feed tubes, one for each spool, allow the E1 to be used in-line with a printer. In practice, this works OK but isn’t perfect. The tubes sometimes slip out during longer prints, so they require frequent checks on long jobs.

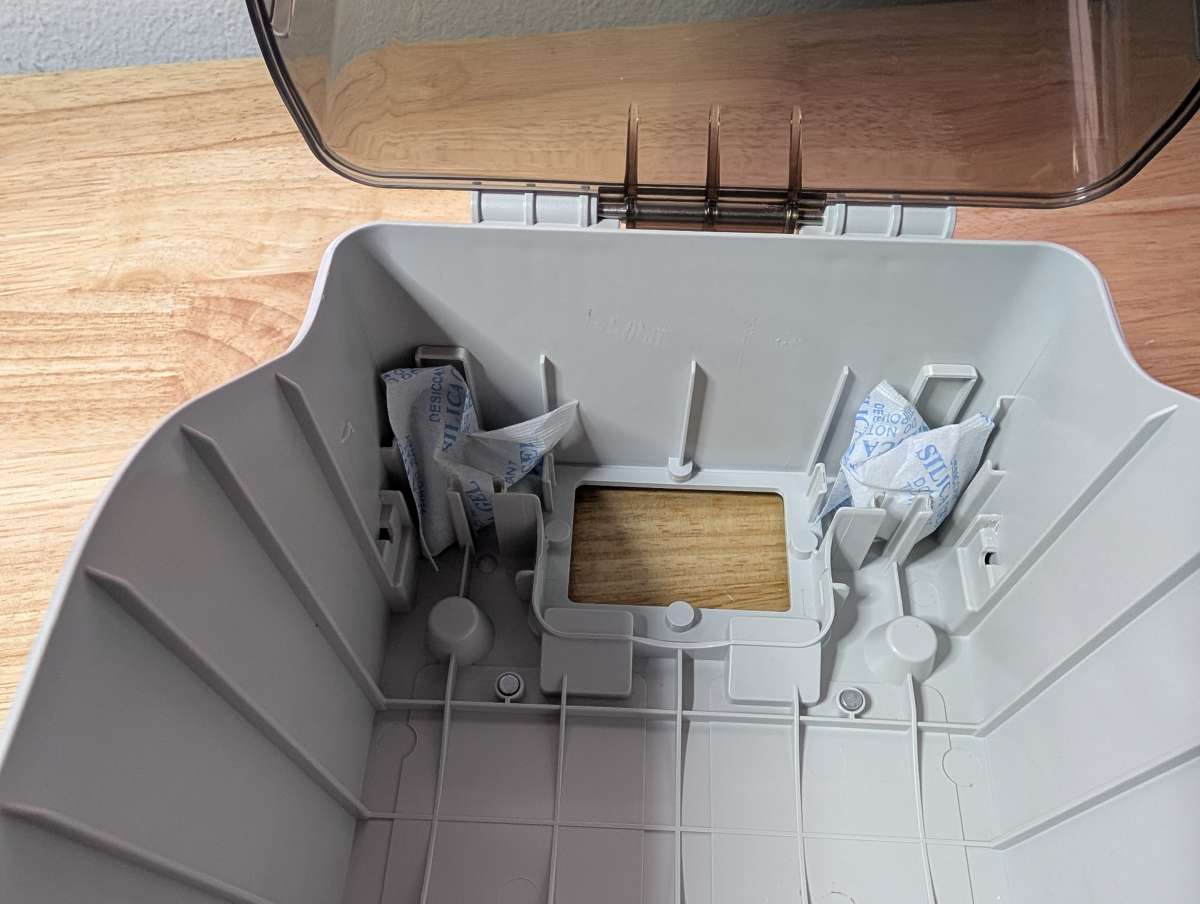

Inside the boxes there is a vented area for storing desiccant packs along with a removable lid that leads to the heaters on the E1’s base.

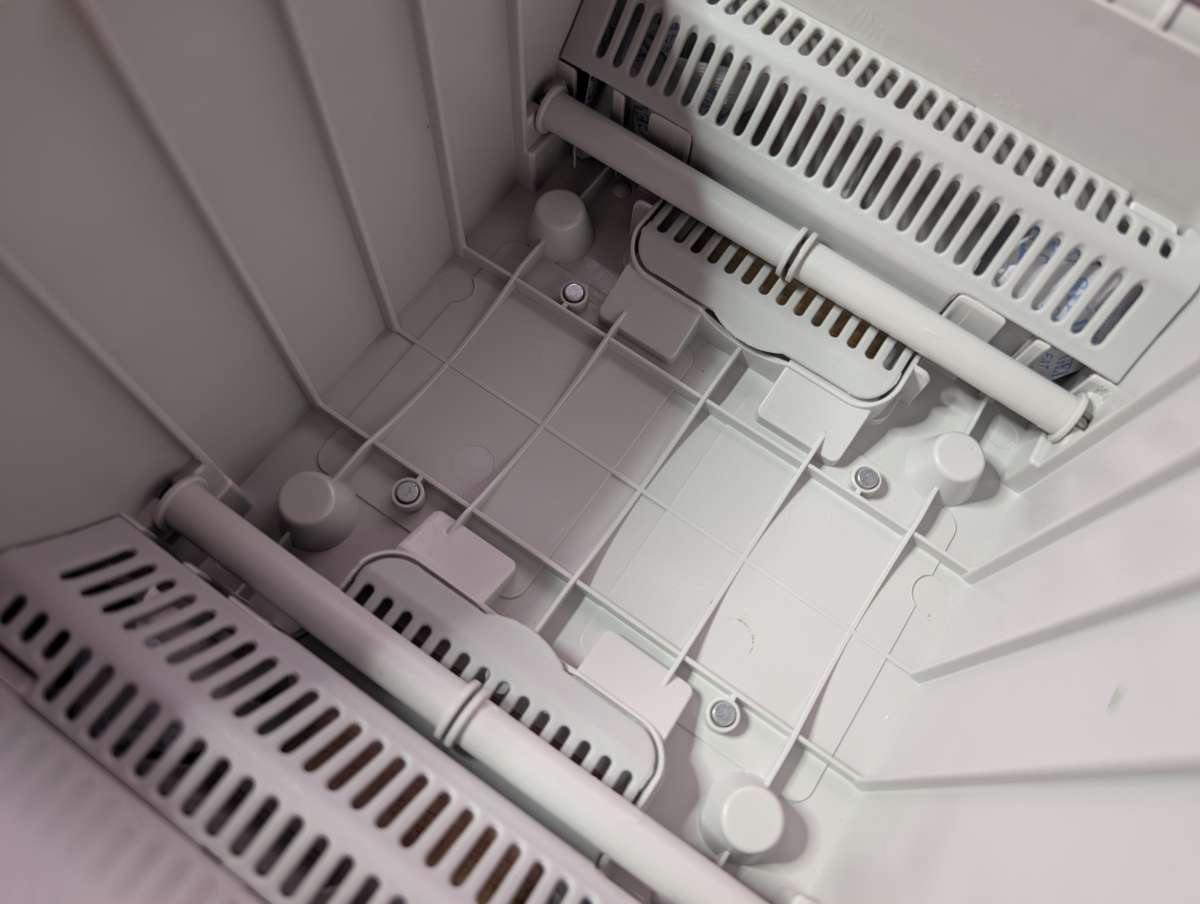

The boxes sit on the base and lock in via these open ports on their bottom. This keeps the boxes stable during drying and forms an airtight seal afterward, which is useful for storage.

Four removable magnetic metal plates, two per box, store on the underside of the boxes and can be popped into place for storing the filament spools. This would be especially helpful if I purchased extra filament spool boxes to keep all of my filament spools dry and ready to use, but the money tree in my yard has long since perished.

There are four rollers in the boxes that allow the spools to rotate easily and with little to no noise at all.

The base is basically a rectangle with a touchscreen on one end and four heating ports.

The heating ports have small removable vents on them and the two sections of the base are numbered 1 and 2 to correspond with the controls on the touchscreen.

You can set temperatures independently for each box. PLA and nylon, for example, require different heat levels, and the E1 lets you run them at the same time without issue. The touchscreen is functional but not highly sensitive, so you need to press with a little extra force at times. Once you get used to it though, navigating the menus is straightforward.

The power switch and port are located on the back of the E1’s base.

There are these odd inserts on one side of the E1, but I haven’t figured out what those are for yet.

There’s a USB-C port on that same side which is used for updating the E1’s firmware when needed.

Assembly, Installation, Setup

Setup for the E1 is very simple since all the parts are already assembled. Place the boxes on the base, remove the magnetic sealing plates from the vents, and plug in the power.

The quick start guide makes it easy to set an appropriate drying temperature and timer, and you can have your first cycle running in about five minutes.

The touchscreen allows you to switch between temperature controls for box 1 and box 2. The screen displays the current box temperature, the target temperature, the current humidity, and the remaining drying time. Typically, the drying cycle takes about four hours.

In the settings of the E1 there are options for having the dryer start automatically as soon as a filament box is placed on the base, running in silent mode, and identifying the boxes.

Connecting the E1 to a printer takes a little bit of finesse. The tubes need to be positioned so they don’t tug or slip, which took a few tries to get right.

I experimented with having the spools feed up as opposed to over, with mixed results. A lot of the positioning is dependent on the location of filament feed for the printer you’re using.

Performance

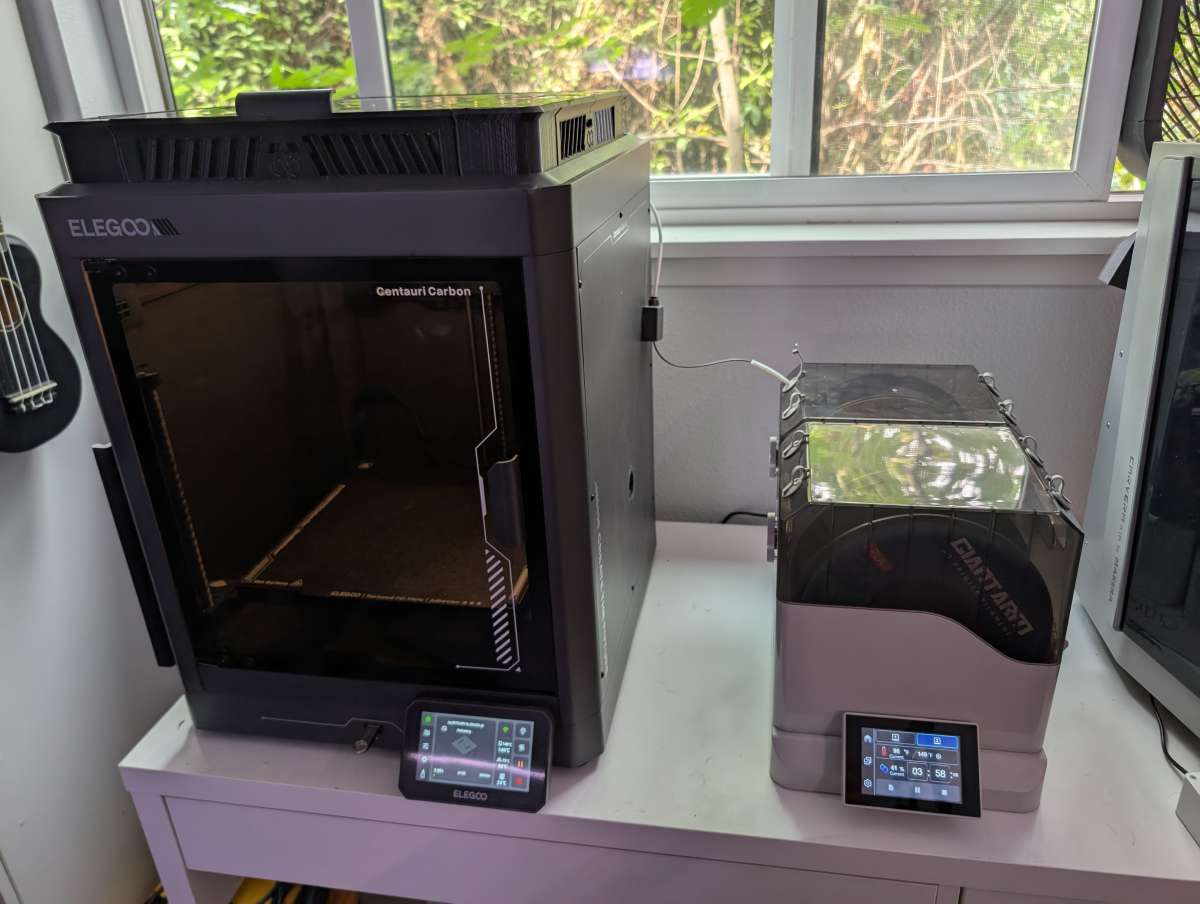

I tested the E1 extensively with various filaments, including PLA, PETG, PETG-CF, and PLA Silk, and used it during extended print runs on the Elegoo Centauri Carbon 3D printer I reviewed in March. The E1 was easy to configure properly for each material and dried them all in about four hours per box.

All of the different filaments showed improved extrusion and layer adhesion. PETG-CF took slightly longer at a much higher temperature, but print quality improved noticeably. Overall, I was producing stronger, more consistent prints without the bubbling and weak layer I would usually encounter.

The humidity sensors tracked conditions in the box, but honestly I relied more on the touchscreen readings once the boxes were placed on the base. Once dried, spools can remain sealed in the filament boxes for several days without re-drying and still perform well.

The touchscreen’s responsiveness and the tube connectors were the only minor frustrations. As I mentioned, the touchscreen sometimes requires multiple taps, and the tube connectors can slip during long prints. Neither issue prevents the dryer from performing effectively, but both require some attention during use.

Overall, the E1 performed consistently, improved my print reliability, and made it easy to store spools in good condition.

Final thoughts

The Chitu Systems FilaPartner E1 Filament Dryer is a practical and well-built system for keeping filament moisture-free. It’s easy to use, offers independent temperature control, and holds up to four spools with airtight magnetic seals. The touchscreen could be more responsive, and the tube connectors more secure, but these are minor issues compared to the benefit of flawless 3D prints. It improves print consistency, protects filament from moisture, and works well with printers like my Elegoo Centauri Carbon and Ender 3 Max Neo. The E1 won’t solve every printing issue, but at the low price of $139, it’s made my prints more reliable and significantly reduced my filament waste.

What I like about the Chitu Systems E1 Filament Dryer

- Independent temperature control for each box

- Magnetic sealing plates keep spools airtight after drying

- Versatile configuration allows it to be used with multiple printers at once

What needs to be improved?

- Touchscreen not very responsive

- Filament feed tubes sometimes shift out of the filament box port

- Tinted plastic makes it difficult to see when filament is running low

Price: $139

Where to buy: Chitu Systems and Amazon

Source: The sample of this product was provided for free by Chitu Systems. Chitu Systems did not have a final say on the review and did not preview the review before it was published.

Check out these other 3D printer reviews!

- Creality Raptor Pro 3D Scanner review – Great in theory, not so great in reality…

- SUNLU AMS Heater review – printing while drying on Bambu Labs AMS? Yes, please!

Gadgeteer Comment Policy - Please read before commenting

Funny, I’m looking at getting one of these, so thanks for the review. There is one other flaw/con (nice to have)? You should be able to put a 2 or 3kg spool in there, right, but the ports are only set up for 1kg spools. It needs a port in the center as well. I guess I can add one, but really, it should already be there.