REVIEW – 3D printers are no longer just for people who know how to use CAD programs to create 3D models and they are no longer for people who have 1000’s of dollars to spend. 3D printers are now available for everyone even a newbie who only has $100 to spend. What kind of 3D printer can you get for less than $100? That’s what I’m going to find out today when I show you the Easythreed K7 mini 3D printer. Let’s check it out.

What is it?

The Easythreed K7 mini 3D printer from MadetheBest is a very small 3D printer that is priced at less than $100.

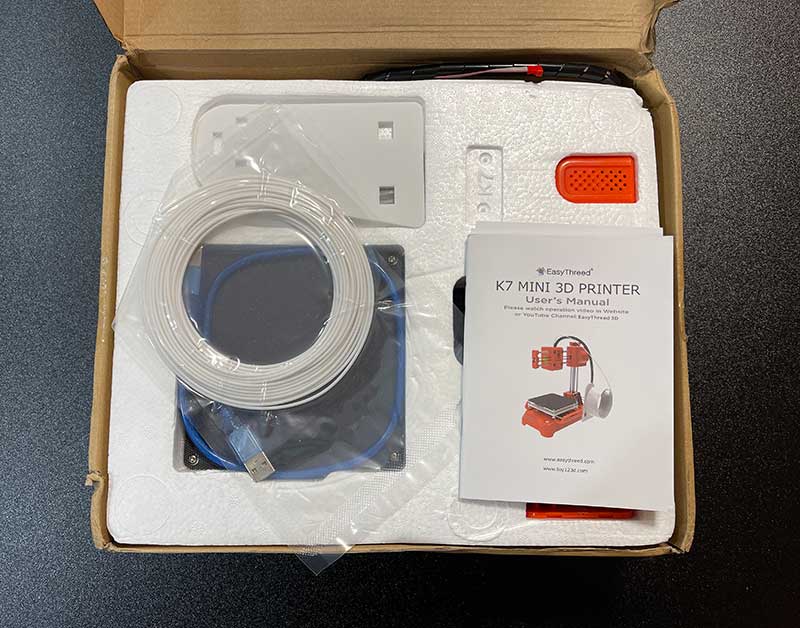

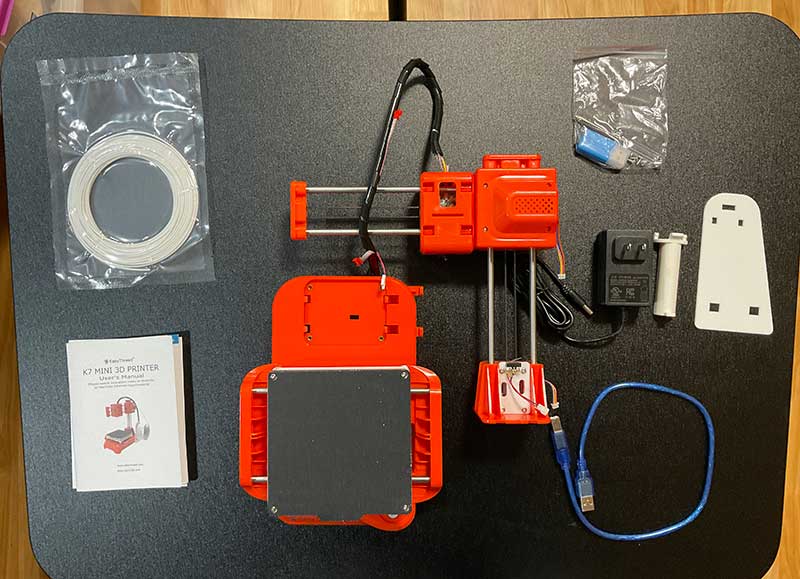

What’s in the box?

- Easythreed K7 mini 3D printer

- A small amount of white PLA 1.75mm filament

- USB host cable

- USB drive with manuals, instructional videos, slicing software, and 2 sample GCODE models

- User manual

Hardware specifications

Print Technology: FDM

Building Size: 100X100X100mm

Number of Nozzles : 1

Nozzle Diameter: 0.4 mm

Layer Thickness: 0.1-0.4 mm

Printing Filament: PLA

Diameter of Filament: 1.75 mm

Printing Accuracy: 0.1-0.2 mm

Slicer Software: Easyware K7, CURA, Simplify3D

Extruder Temperature: 180-230℃

Print Speed: 10-40 mm/s

FilaFormat: Input:.Stl/obj, output:.gcode

Power: 12V, 30W

Machine Size: 175x235x270mm

Some assembly is required

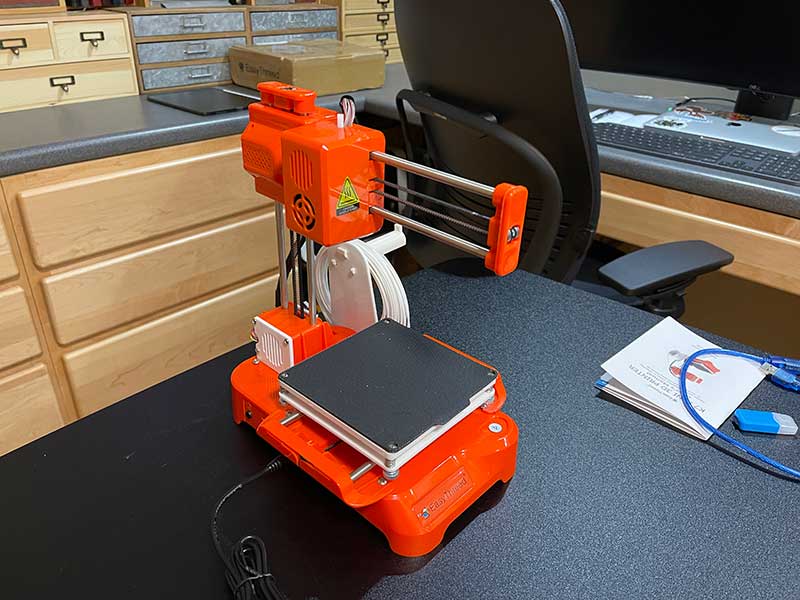

You will have to put together the printer but don’t worry because it’s quick and easy. There are just two main parts. There’s the base with the print bed and the nozzle mechanism which snaps into the base.

From there you just connect several small plugs and secure the nozzle mechanism with 4 screws.

Then you snap on the filament holder and you’re all set!

You can watch me put the Easythreed K7 3D printer together in my demo video below.

Design and features

On the left side of the Easythreed K7 3D printer, you’ll find a Home button that moves the printing nozzle to the back left corner of the print bed. On this side of the printer, you will also find a microSD card slot, feed mode selector switch, USB host port, and power connector.

The opposite side of the K7 does not have any buttons or ports but the front of the printer has a Print/Pause button.

You’ll notice that I didn’t mention a power switch. That’s because there isn’t one! Yeah, what the heck right? In order to turn the printer off, you have to yank out the power cord. Not exactly an elegant solution.

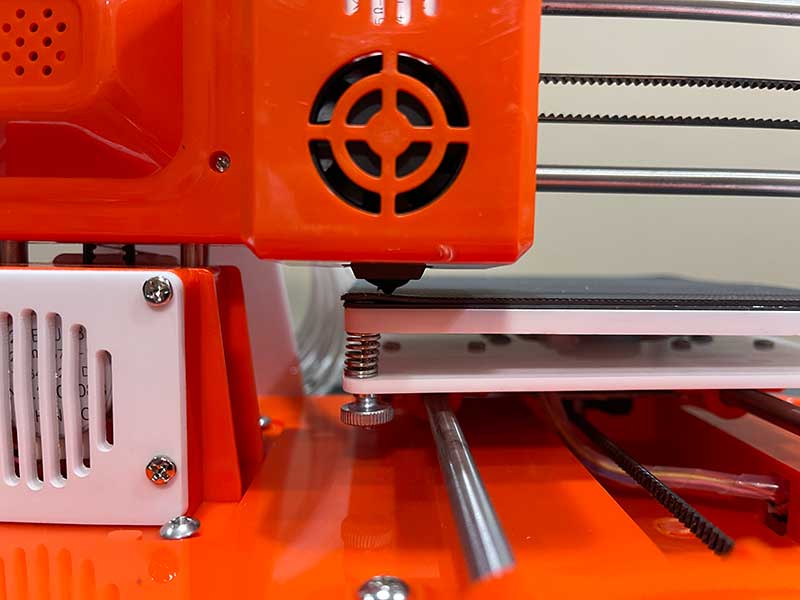

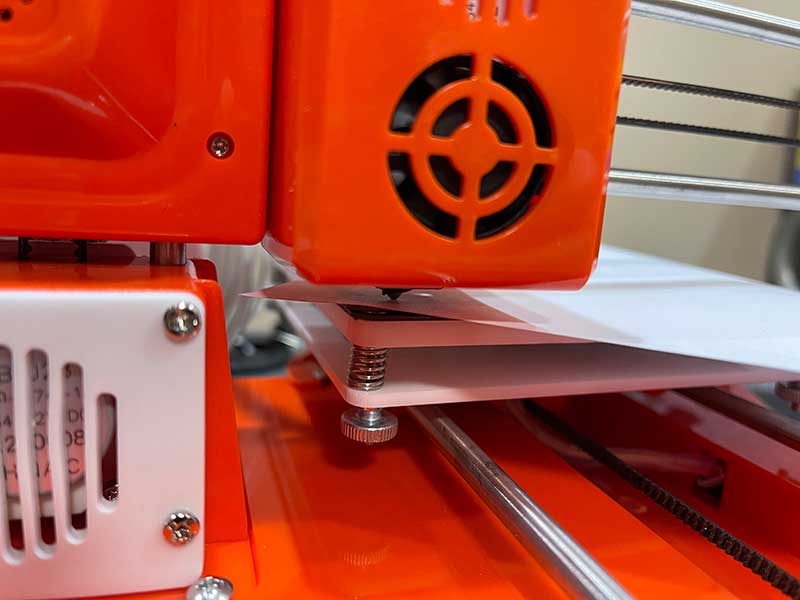

Calibration

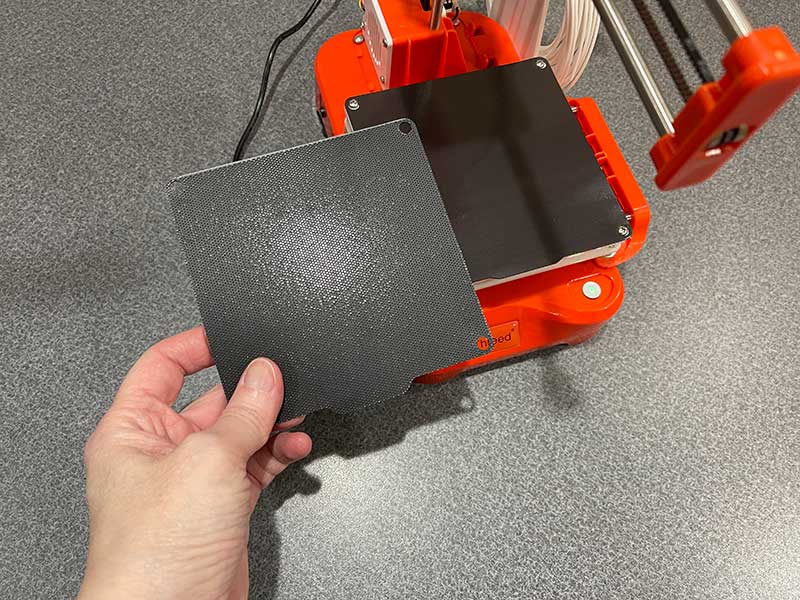

Before you can print your first 3D model, you will need to calibrate the printer.

To do this, you use the four corner screws below the print bed to lower and raise the bed so that a sheet of paper can just fit between the print nozzle and print bed surface. You have to do this for all four corners.

Let’s make our first print!

A USB card reader with a microSD card is included with the Easythreed K7 3D printer. This card has manuals, instructional videos, slicing software, and 2 sample g-code 3D model files. What is g-code? G-code is the computer language that tells a 3D printer how to control the nozzle movement to print a 3D model.

The K7 3D printer can only print g-code files. If you want to print other 3D models and search the net for free models you’ll find a lot of STL files. STL stands for Standard Tessellation Language or STereoLithography. This type of file is in a format that describes the surface geometry of a 3D object. More about STL files later…

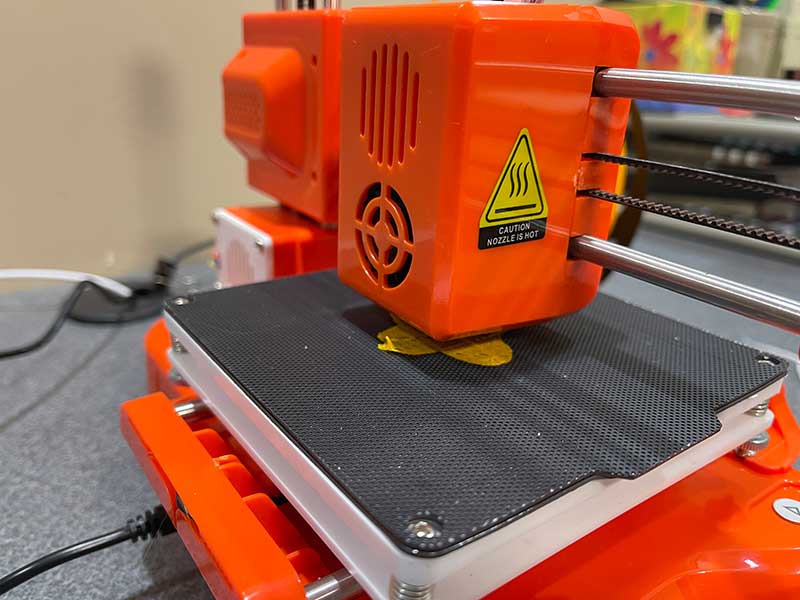

To load the filament, you place it on the spool holder, feed one end of the filament into the printer, make sure the feed switch is set to FEED, and plug in the power cord. The printer nozzle will heat up and within a minute or so, and you’ll be able to start pushing the filament into the printer. When you see melted filament coming out of the nozzle above the print bed, you’re ready to start printing.

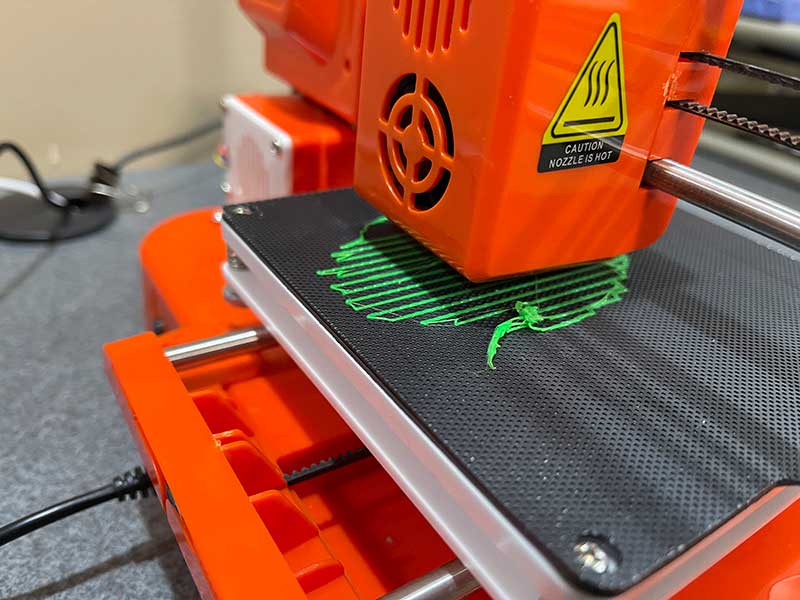

With a g-code file stored on the microSD card and the card inserted into the printer, you flip the feed switch to the center position and press the “play” button on the front of the printer. A minute or two later the printer will start printing.

The first thing it will do is print a “raft” which is a base for the print.

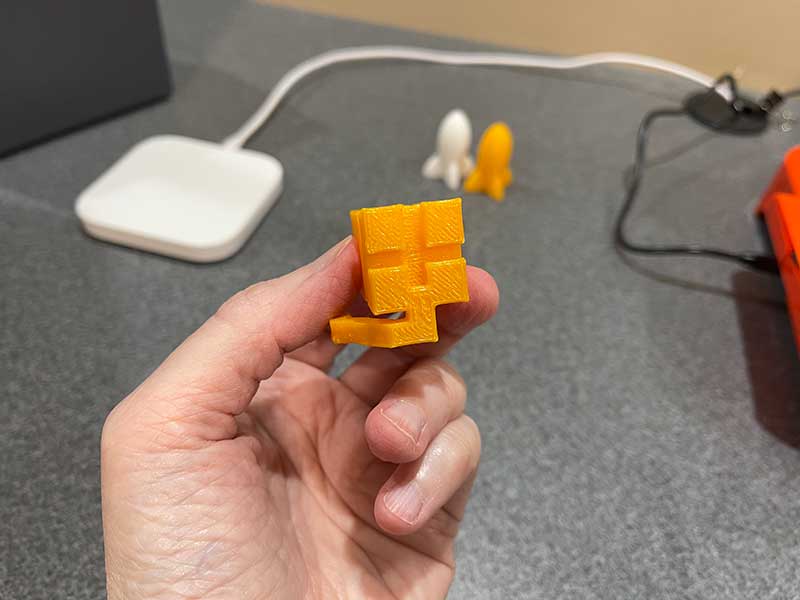

When printing is finished, the nozzle will lift and you can remove the magnetic print bed and peel off the print. The raft breaks away from the bottom of the print revealing the 3D model.

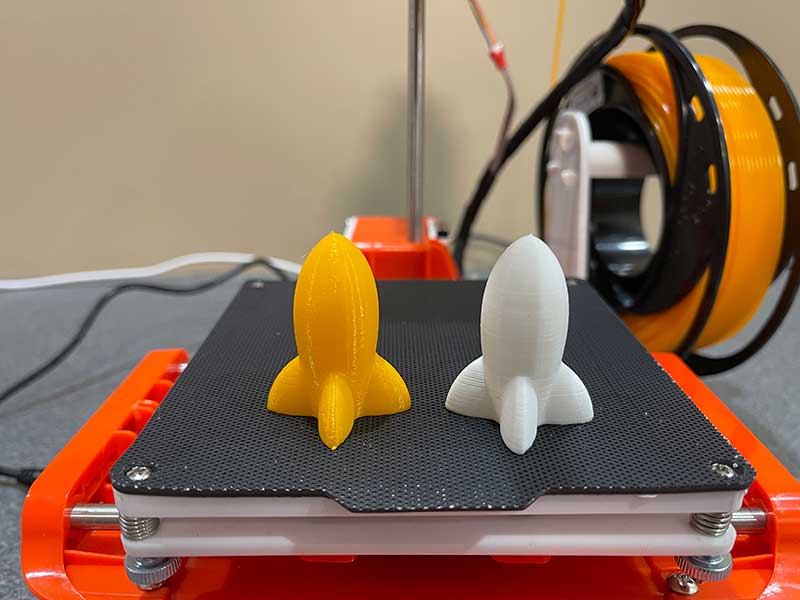

The time it takes to print a 3D model is dependant on the size of the print. Some models like this little rocket can take 30 minutes or so.

The Easythreed K7 3D printer comes with a small amount of white filament, but I wanted to try some other colors so I purchased a box of 4 spools from Amazon.

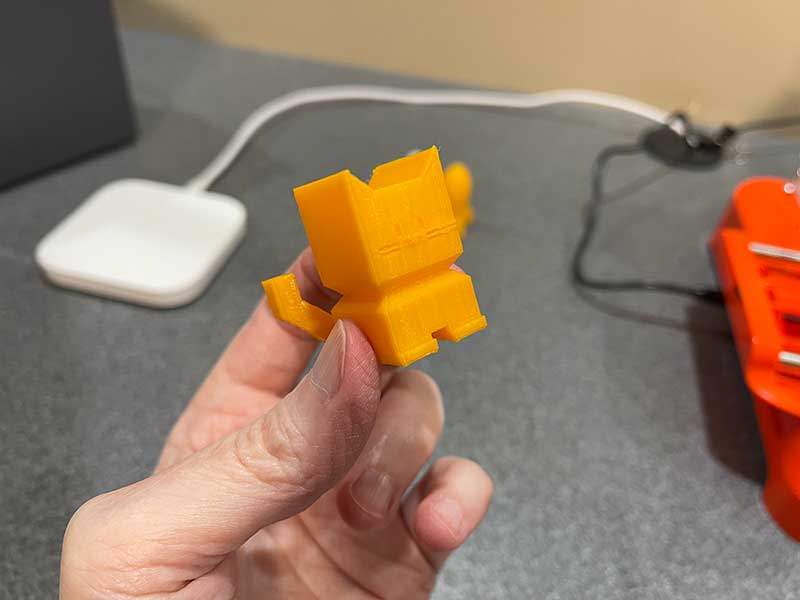

Here’s the other g-code model from the included micro SD card printed in orange filament.

With two successful prints under my belt, I was feeling like a 3D printing guru and decided it was time to branch out and find other g-code models. Remember, Google is your friend. I ended up on Thingverse.com

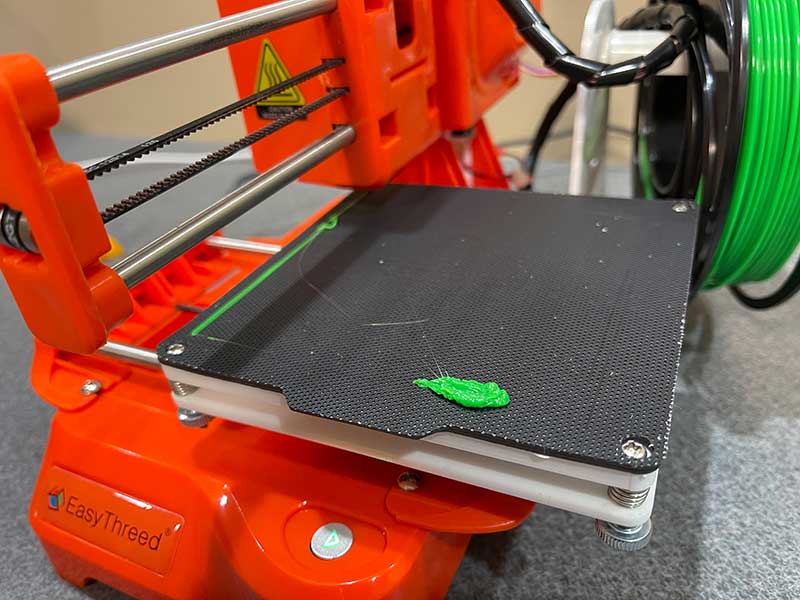

I found a model file, loaded it on the microSD card and… this happened. The print nozzle went from the home position to the front and sat there making a blob. Ok, I’m not a guru after all… <sad>

I don’t give up so I found another model file and tried again.

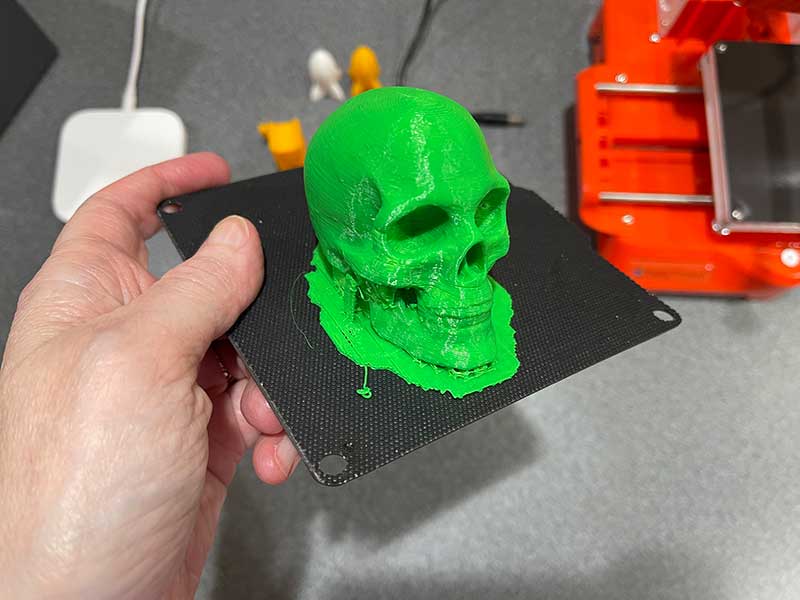

This will be great in a few weeks for Halloween! This print was also my first experience with the supports that some models have that help the printer span voids. You can see a small support under the skull’s cheek bone. There was more under the back of the skull. I had to use needle-nose pliers to remove the extra material.

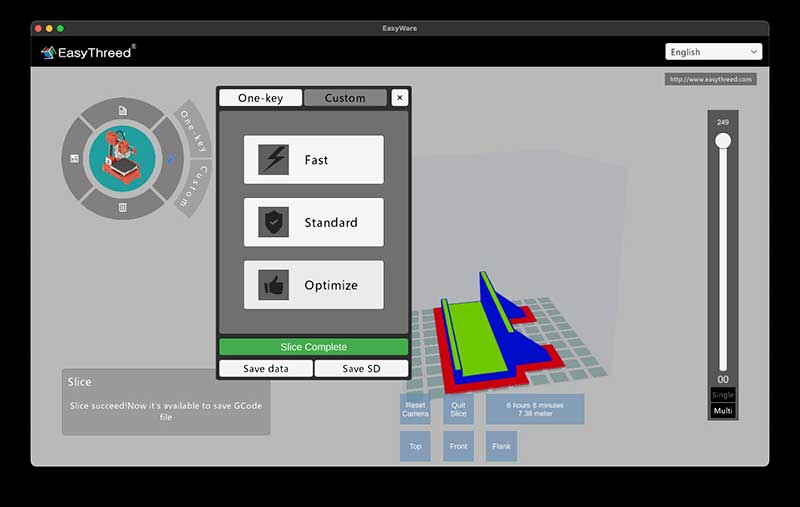

For my next test, I decided to really flex my 3D printing powers and slice up an STL file to turn it into a g-code file. Remember, the K7 can only print g-code files and most of the 3D models that you find on the net are STL files. How do you convert them? You have to use slicing software. Luckily, Easythreed provides two programs for Windows and Mac on the included microSD card. There’s Cura and Easyware. The Cura software would not run on my M1 MacBook so I downloaded and installed the latest version.

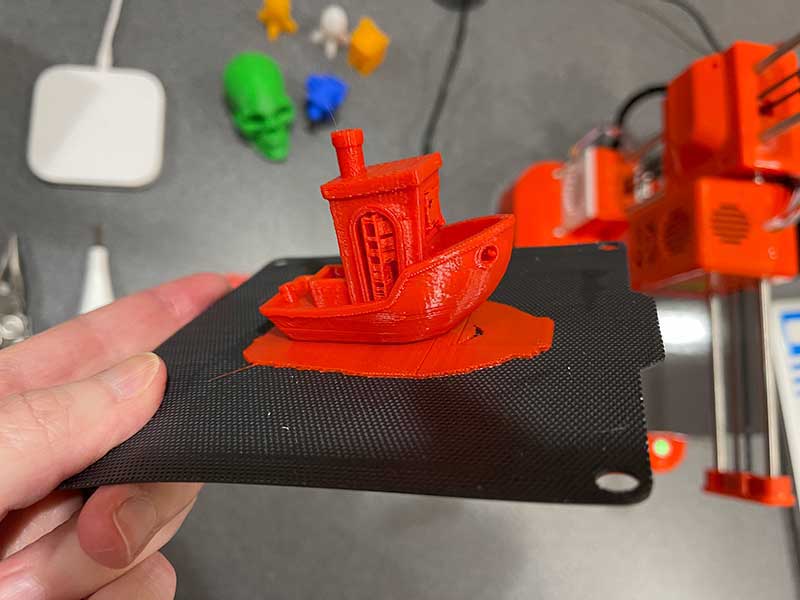

My plan was to print Benchy, which is a small boat that is the equivalent of programming “hello world” for 3D printers.

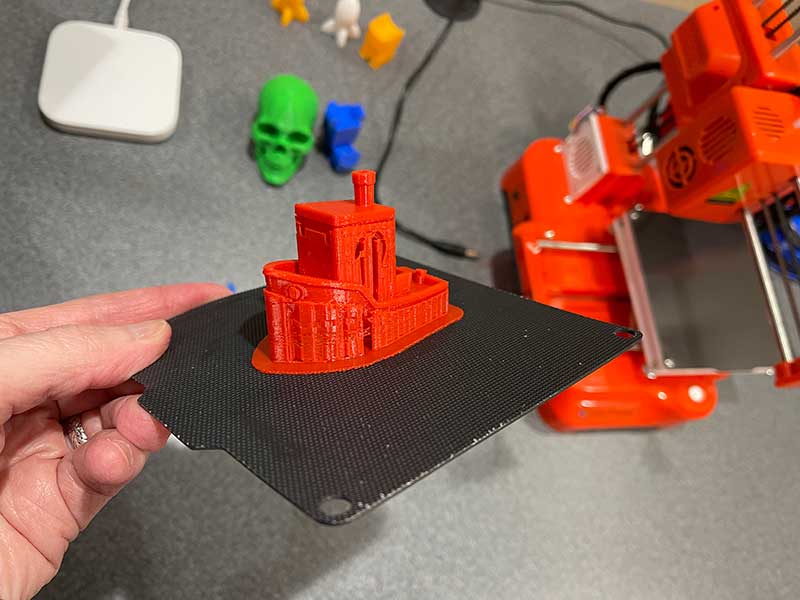

I downloaded the Benchy STL file and sliced it with Cura and printed it… Hmmm…. look at all that extra material.

Even after pulling the outside stuff off, the interior of the boat’s cabin was solid material that I could not remove.

Back to the drawing board…

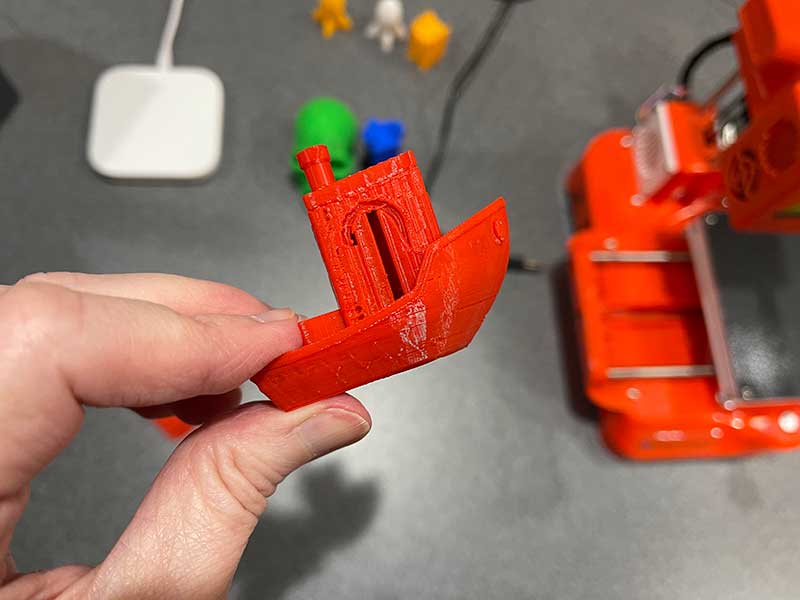

I took the same STL file and used Easyware to slice it into a g-code file and this was the resulting print. Looks a lot better!

After removing the supports and raft. Yay!

Now it was time to create my own model from scratch!

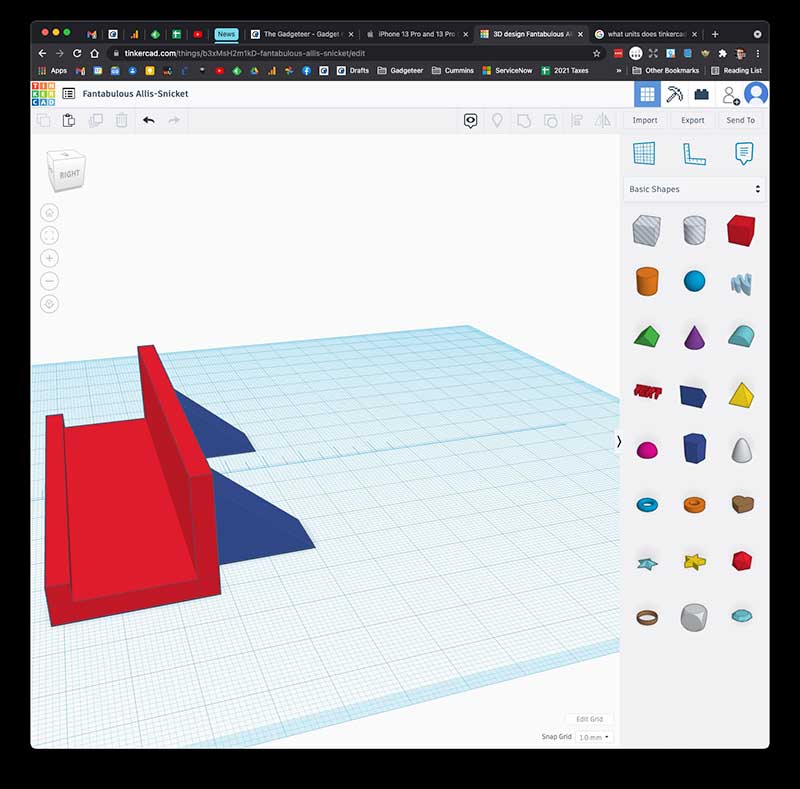

Using a free online app called Tinkercad, I created a… Ummm… it was supposed to be a phone stand. Hey, cut me some slack, I’m not a CAD person (yet). The software provides you with a variety of shapes that you can stretch, shrink, and rotate to create objects.

Then when you’re done modeling, you export from Tinkercad to an STL file and then use slicing software (I used Easyware again) to create a .gcode file.

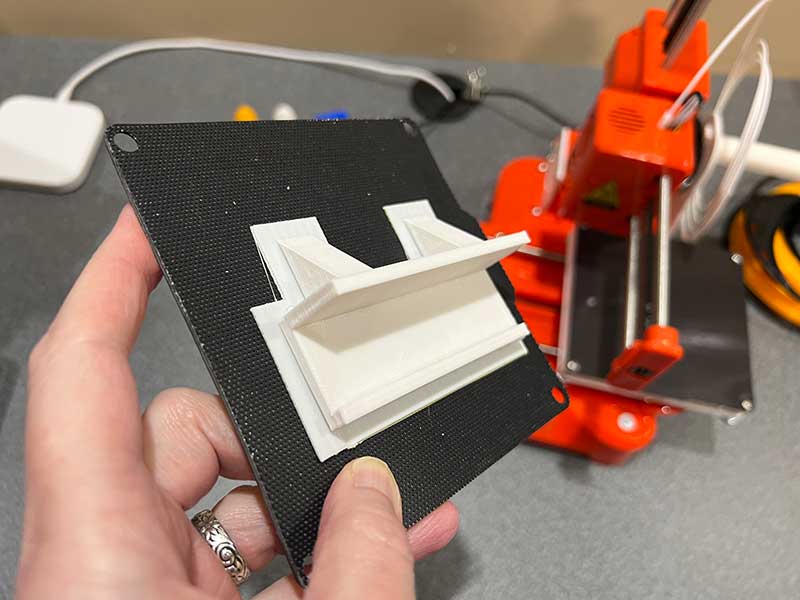

And there it is! My model was a successful print, but it wasn’t a successful phone stand because the front edge wasn’t tall enough to keep my phone from slipping out. Oh well. I’ll try again at some point because experimenting is what makes 3D printing such fun.

See it in action

What I like

- The price

- It’s portable!

- Easy to use for a beginner

What I’d change

- Add a power switch

Final thoughts

I didn’t know what to expect when I accepted the offer to review the Easythreed K7 mini 3D printer. As a complete novice, I figured a 3D printer for kids would be a good place for me to start and it was! Assembling the printer was simple, and printing wasn’t difficult once I figured out which slicing software to use. Am I a 3D printing master now? Ha! Far from it. But this sub $100 3D printer has sparked an interest in this hobby and I can’t wait to try a “real” 3D printer. But until then, if you’re looking for an inexpensive and easy way to try out 3D printing without spending a lot of money and head-scratching, I can recommend the Easythreed K7 mini 3D printer.

Price: $99.99

Where to buy: MadeTheBest (use ETK7 to bring the price to $85.99 – expires 10/14/21)

Source: The sample for this review was provided by MadeTheBest.

Gadgeteer Comment Policy - Please read before commenting

This looks really cool! A few of my coworkers have 3D printers, I think this is right in my price point if I wanted to dabble with it before taking the leap to a “real” machine.

Ross, if you do end up getting one, please let me know what you think about it.

Julie, while the unit looks interesting (certainly at that price point), how easily would an 11 year old figure out the little software nuances you uncovered (and be able to work around them?)

Michael, How tech savvy is the 11yr old? I think with a little bit of trial and error, they would be fine and it would give them self-esteem to figure things out on their own or with a little help from an adult.

Quite savy. He builds his own ‘Lego’ custom cars, figurines, etc. I was thinking this might interest him in drawing (no pun intended) together his Lego building with custom parts he might enjoying crafting, and at the same time learning about 3D.

That Sounds like a great idea and at this price point, it’s not too painful to give it a try.

Ordered… (Early Christmas shopping would be wise for folks this year!)

Good luck! You’ll want to get some filament too!

Your 11 year old may find this works well for him. He can design and print things to assemble using screws without needing nuts (size the holes such that the screw fits through the outer piece and screws into the plastic on the inner piece).

So even though the bed is small, he can design bigger components and put them together.

But, beware that you may be bitten by the designing/printing bug too!

well I have a Easy threed k9 model also I own 2 other machines (3 years old) well this thing is fantastic ,they turned a technical Nightmare into a dishwasher Wow auto bed leveling ,and aut feed and above all auto printing . Load the file ,insert sd card and filament ,press button 2 times and bingo clean dishes no no I mean a ready to go 3d object.

On the website link you give, the filament spools run $35 and up. Did you use these (four colors would be an extra $140)? Or are cheaper ones that work with the printer available? One of the things I hate about 2D printers is the give-away-the-printer gouge-’em-for-the-ink pricing.

Jeffrey, I bought my 4 pack of filament from Amazon. I think included the link in the review, but here it is again: https://amzn.to/3ulcINH

Ah, that’s much better. And glad it’s tested to work!

Any 1.75mm PLA should work. Wow, I sound like I know stuff!

This guy reviewed the printer on his youtube channel – he’s a little cheesy and sometimes too technical but he has some good insights/considerations into this also.

I do like that he tried a variety of filaments and models (squeezy shark/dinosaur figurines sound pretty cool!) https://www.youtube.com/watch?v=u8K1VPwcGjs

I don’t agree with everything he says but he makes a good point that you may want to recalibrate the base before every print to make sure it hasn’t gone screwy on you, since it’s only held by those springs and corner screws, which may come loose over time.

Thanks Ross 🙂

I’ve been looking for a very cheap entry level 3D printer and this one would seem to fit nicely. Just ordered one and it should arrive within 7-14 business days.

Robert, please come back after you’ve used it for a while and let us know if you agree with my review or have a different opinion.

Promised 🙂

As promised, my experience. The short version: terrible…

1. Delivery is about three times as long as stated on their website. Also, the extra PLA I ordered is still not shipped, 4 weeks after I ordered it. No reply on mails I sent them. Terrible customer experience.

2. The printer itself is of excruciatingly bad build quality. Calibrating the print bed is a nervebreaking exercise, especially where you have to unplug the power and move the bed / printer head, manually. I’m terrified the drive belt(s) will break. Even then, I tried different paper types (weight). Most of the times, even the first layer won’t stick, even when the print head it actually touching the bed (which is wrong, of course, but just for the sake of testing the stickyness). And if it sticks, the model will release from the bed after layer 2 or 3, so the print is ruined. The print bed also feels cold, like the heating element below is not working (although everything is connected properly; can’t do anything wrong there).

I’ve had some experience at work with the Ultimaker 3 and another kids 3D printer at the school of our son. Of course, those are printers from a totally different price range, but still, they work like a charm. My K7 (perhaps it has a quality issue?) is just terrible. I already mailed MadeTheBest and asked to return it and get a refund. But I’m afraid I won’t get an answer, based on my previous attempts of contacting them.

Bad product, bad company. I’ll never buy anything there again.

Robert, I’m sorry that your experience was much worse than mine. I didn’t claim that this was a great 3D printer, and I had my share of glitches/problems with it as mentioned in the review. It sounds like your main problem is with leveling the bed and that can be a bit frustrating since it’s a manual process. I just used regular typing paper and made sure that the paper could slide between the nozzle and the bed but that it still felt a little scratchy/draggy when doing so. Also from what I can tell, the bed on this printer is *NOT* heated. As for the customer service quality of Madethebest, I’ll direct them to your comment so that they can see it.

Thanks Julie. I actually have an update. I got a tip from someone to use a glue stick on the bed, prior to printing. So I did that (regular Pritt stick) and suddenly it printed like a champ! So that leads me to conclude that I did the leveling corrrect, but that the bed surface is not “roughed up” enough or that the included PLA is not sticky enough by itself.

Still, I think the build quality of th K7 is bad, allignment and movement of the print nozzle are wonky, at best. I’ll return it anyway and look for a more expensive but better machine.

I’m glad that you were at least able to print something with it. All of my prints have looked “ok”. I know they aren’t great, but it’s just been fun learning about 3D printing at such a low entry price point.

Robert,

If your experience is with an Ultimaker, a $4,000 (minimum!) printer, I can see how your experience would not be what you had hoped.

3D printers are notorious for being finicky. One of the most popular printers, the Creality Ender, is reported to need consistent tweaking to keep it printing well. And it costs about twice as much as the Easythreed. It also requires a glue stick for reliable adhesion to the print bed.

So don’t let this experience turn you off to 3D printing. I imagine there is still a lot you could learn about 3D printing with the Easythreed printer. Just be sure that when you do decide to upgrade, get one that does not need as much adjusting. And for heavens sake get your filament from Amazon or someplace that is not having sourcing problems with all the supply chain issues!

My experience with a Prusa Original is that even in its price range, there is some level of attention needed to print things reliably. Just not as much as the $200 – $500 printers.

In my (short) experience, 3D printers are as much a money pit as any hobby. Since I got it and started learning, I have added a Raspberry Pi for wireless printing, extra tools, a supply of isopropal alchohol and acetone to keep the bed clean, bags and desicant to store filament, the list goes on.

I had no idea when I started on this journey.

But to me it is a fascinating hobby. I spend way too much time at it, but I also have way too much fun with it.

Robert,

I too ordered one, but have been unsuccessful in obtaining any ship date or tracking information. Was that provided when you placed the order?

No, I haven’t received any order information from them, but 7-14 business days is what it states in their shipping policy. And it taks 1-2 business days to process an order. I ordered Thursday, so if I don’t get an update by Tuesday, I’m giving them a call to check if they can actually deliver within an acceptable time frame. And if not, I’ll cancel the order.

Contacted them and received the following:

Dear customer,

Thank you for your mail.

Due to our national holidays, we will not be able to reply you from Oct 1st to Oct 7th.

We will get back to help you on Oct 8th when we back from holidays.

Thank you for your understanding.

Best regards,

Madethebest Team

Julie, the reason why you had so much material left (and the cabin was filled in) on the Benchy is because supports were turned on in Cura. In addition to the Benchy being a hello world, it’s also a calibration model of sorts used to see what settings should/need to be changed in slicing your model.

Cura is not the most intuitive programs (especially for new users), but after hunting around a bit you’ll find a visibility option for settings. I would turn everything on, then look for the “support ” area. At the very top is a check box to “generate supports”. If you uncheck that, the Benchy should print fine using Cura. Hope this helped. 🙂

Len, thanks so much for that tip! I had no idea and I would definitely rather use Cura because even Easythreed says it performs better than the Easyware software.

Yeah, usually the company-provided slicing software is either a fork of an older version of Cura or a barebones program that doesn’t offer the settings you need for error-free prints. You’re quite welcome by the way, and best of luck in your 3d printing adventures! If you run into any other problems or have questions just reply back to this & I’ll do my best to help you.

Len, You are awesome! Thanks! I’m sure this will help others who might be buy the K7 too.

I started with an Easythreed about six months ago to see if I could get a grip on the hobby. I loved it!!

I now own 2 more expensive machines and my 8 year old Grand daughter has my easytheed and loves using it.

Excellent item for her to experiment with and learn the programming and design side of 3D printing.

She first started with 3D slash and now uses some other design program she found useful.

My Xmas present too her from grandad is a much bigger better printer this year.

I fully recommend the easytheed range.

Dave, thanks for sharing that. I’ve not heard of 3D slash so I’ll have to check it out. What printer are you getting her from Christmas? I’m still trying to figure out what to get for myself as I think my next review offer for a printer has fallen through.

hi gadgeteer.i am a rookie with this stuff and have been looking for a cheaper 3d printer using my chromebook app. i could hopefully use my tindercad/thingiverse designs.my question is if i design something with 2mm holes within it,can the easythreed handle it with a quality/accurate print? this will be radio control car parts with a max length of 90mm,so will fit on the bad.

Billi, I don’t think this printer has the best accuracy. It’s more of a toy that’s fun to learn on, but not really good enough to print accurate parts.

Like your article. when you started your phone holder, before you even start, how do you get the model on to the slice pad. I am a novice novice. don’t know the beginning of slicing. get the slicing page up on the screen and have my model in my hand. What happens next. that’s where I’m stuck. do I need another page to type in a TLS code to put my project on the slicing board? Been trying for days and looking everywhere and even bought 3Dprinting for dummies but that won’t be here for another week. canyon help me on that part. Can’t go any further until get down. Thanks in advance. Wayne

Hi Wayne again, okay, found out how to start with cad and found out there is a lot more to getting your project on the table. Now learning to creat a tapered cylinder on my creation bed. Playing around with that, slow progress but required I guess. Will post again if need any help. Thanks for your patience.