Look, we’ve reviewed plenty of 3D printers here at The Gadgeteer. From budget FDM machines that churn out desk toys to resin printers that can handle detailed miniatures, we know this tech inside and out. But Apple just dropped something that made us sit up and pay attention. They’re 3D-printing millions of titanium Apple Watch cases. Not prototypes. Not limited editions. Millions of production watches.

Let that sink in for a second.

From Hobby Tech to Industrial Behemoth

The 3D printers we test typically cost anywhere from a few hundred to a few thousand bucks. You set them up in your garage or spare bedroom, download some STL files, and start making stuff. Maybe you print a phone stand. Maybe you print replacement parts for your old gadgets. Some of you are printing truly impressive functional parts.

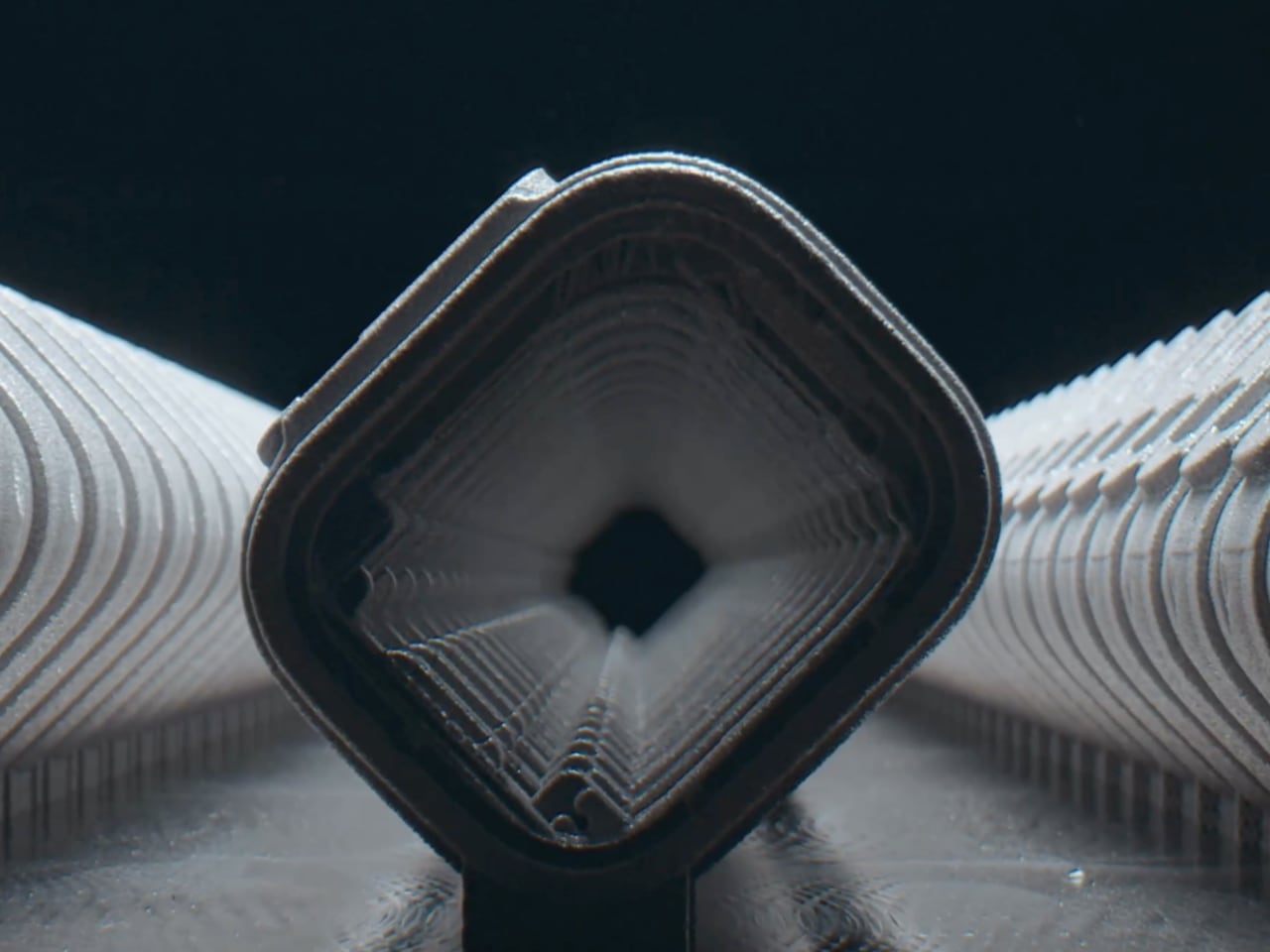

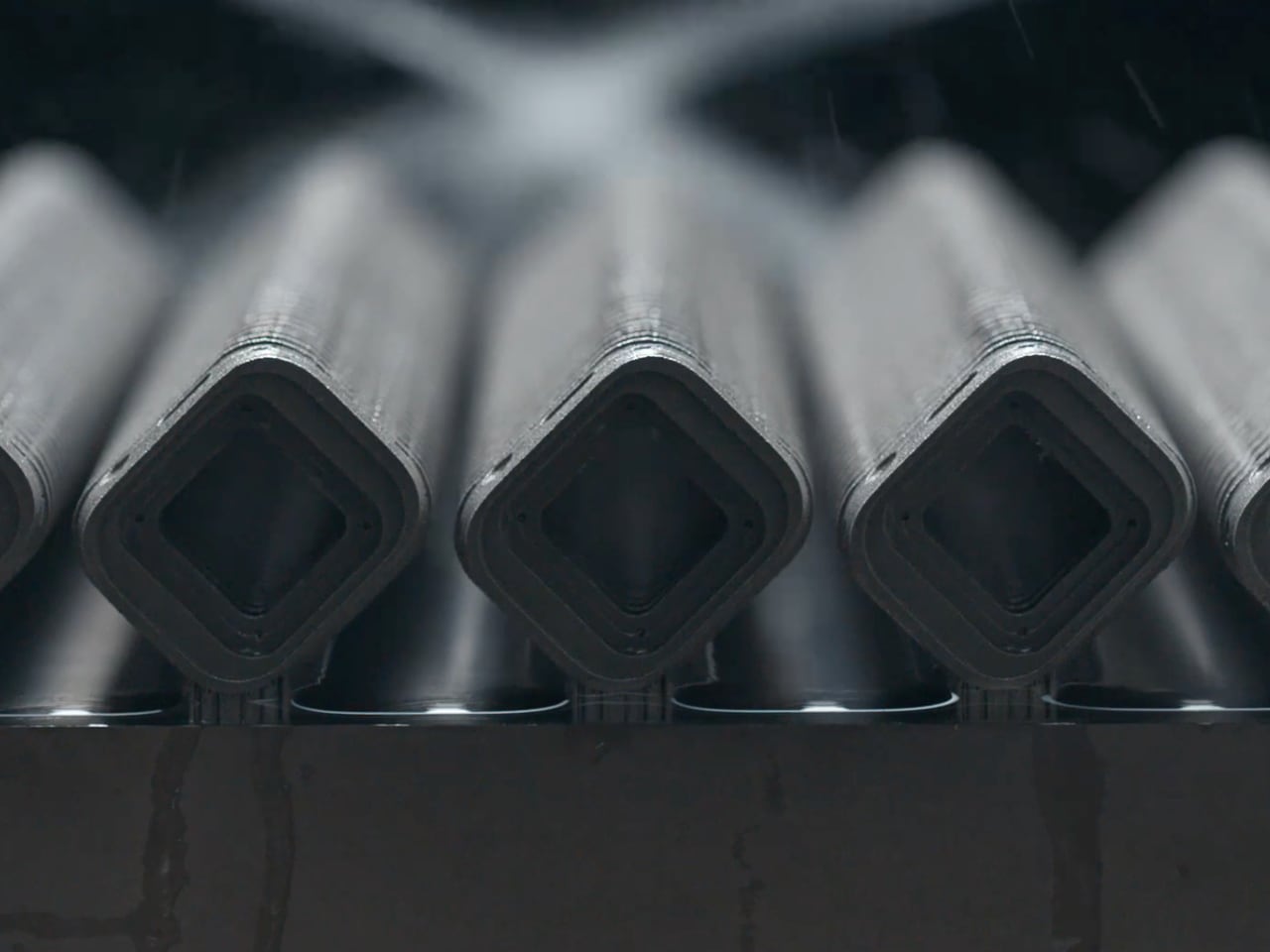

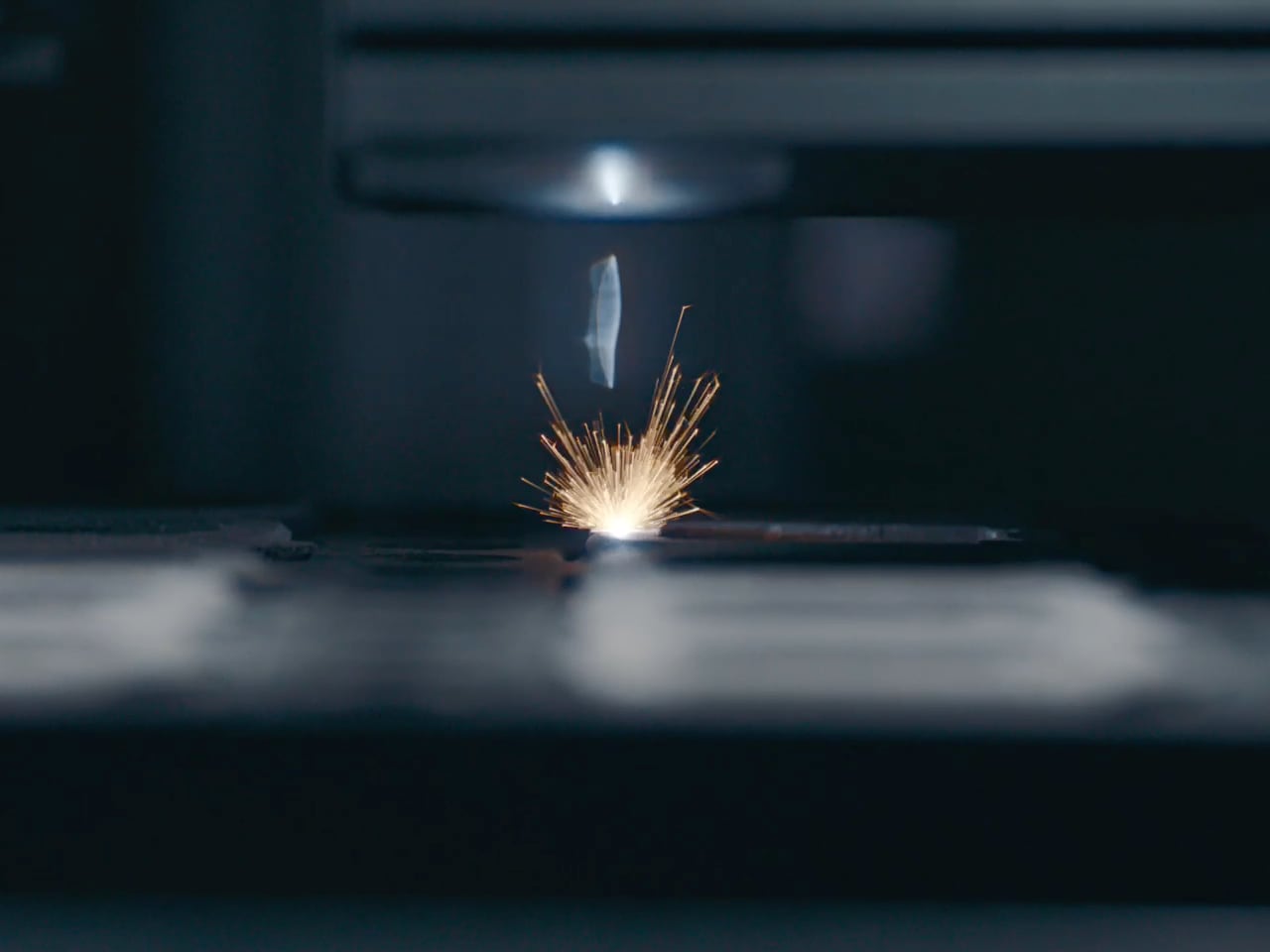

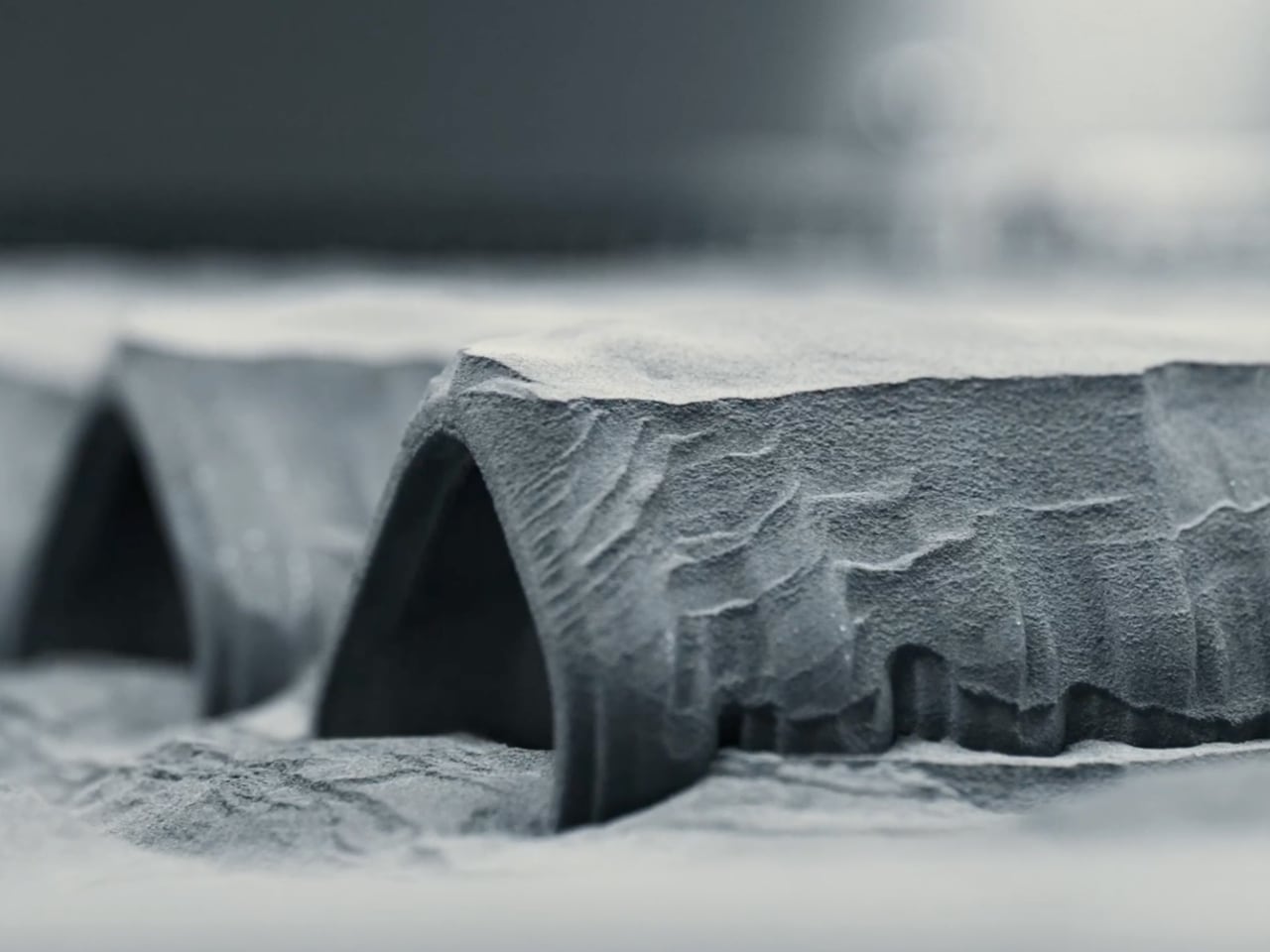

Apple’s operation? Picture rows of industrial printers that look like white Lego skyscrapers, running 24/7, each one housing six lasers working in perfect sync. Each laser is building a single watch case layer by layer, over 900 layers total, with precision down to 60 microns. That’s roughly the width of a human hair. They’re using 100 percent recycled aerospace-grade titanium powder, the kind of material that would make your desktop printer cry.

Every Apple Watch Ultra 3 and every titanium Series 11 now rolls off this production line. The cases look identical to traditionally machined titanium, with that mirror-polished finish that catches light like a luxury timepiece. But here’s the kicker: they’re using half the raw material compared to traditional manufacturing. That’s over 400 metric tons of titanium saved this year alone.

The Technical Stuff (Because We Know You Care)

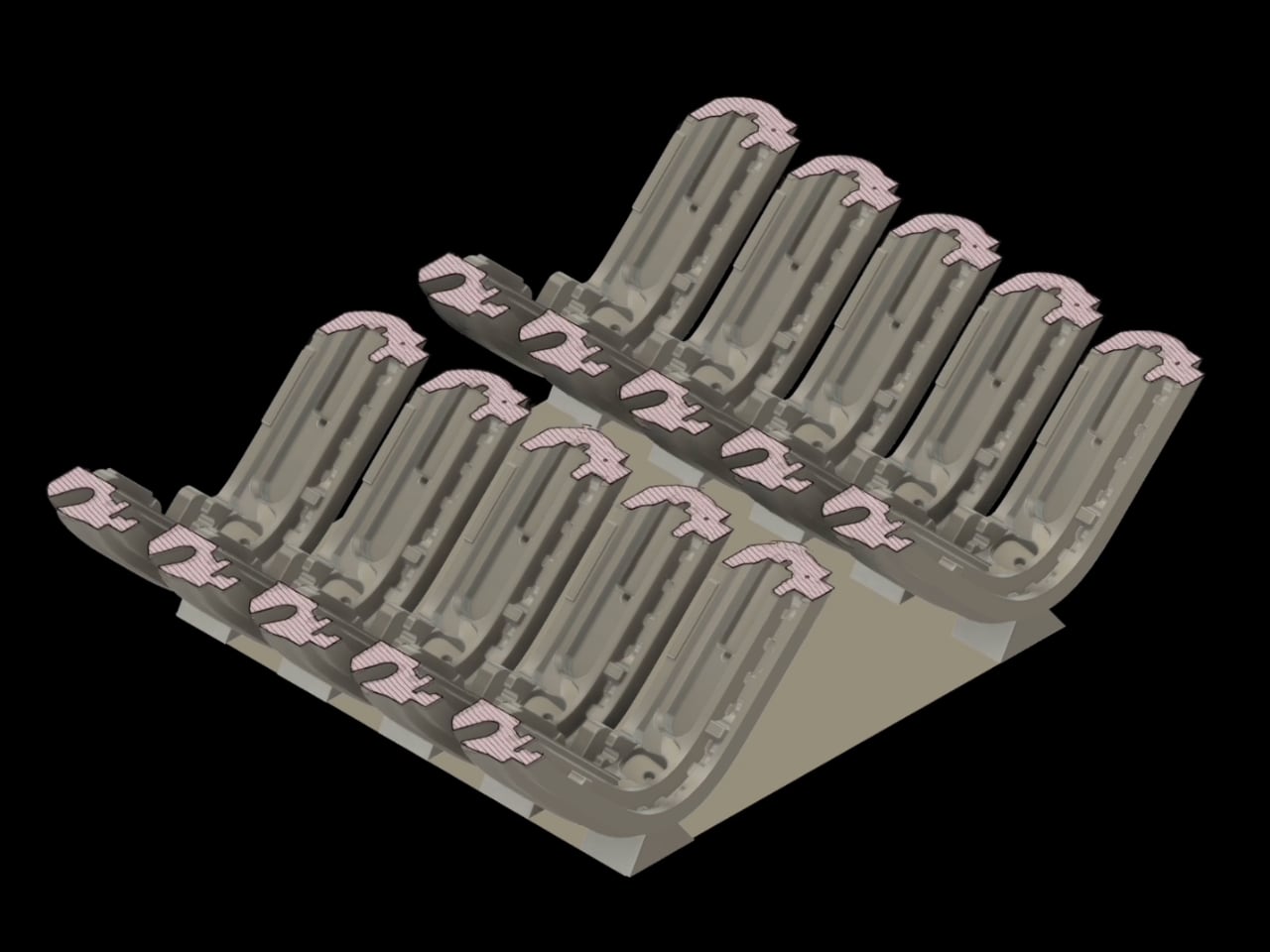

Traditional watch case manufacturing starts with a big block of titanium and machines it down until you get the shape you need. All that extra material? Waste. 3D printing flips the equation. You only use what you actually need, building up instead of cutting down.

But titanium powder is tricky. It needs to be atomized down to 50 microns, basically ultra-fine sand. The problem? Titanium powder with too much oxygen content becomes explosive when you hit it with lasers. Not ideal for a production line. Apple’s materials science team had to engineer a low-oxygen titanium powder that could handle six simultaneous lasers without turning into fireworks.

Once the printing is done, operators vacuum off excess powder in what’s called “rough depowdering.” Then an ultrasonic shaker gets the powder out of all the little nooks and crannies during “fine depowdering.” A thin electrified wire saws between each case while liquid coolant keeps everything from overheating. Finally, an automated optical inspection system checks every dimension and surface before the cases move to final assembly.

The precision is absurd. Each layer has to be exactly 60 microns thick. Apple’s VP of Product Design, Kate Bergeron, put it perfectly: “We have to go as fast as we possibly can to make this scalable, while going as slow as we possibly can to be precise.”

Why This Actually Matters

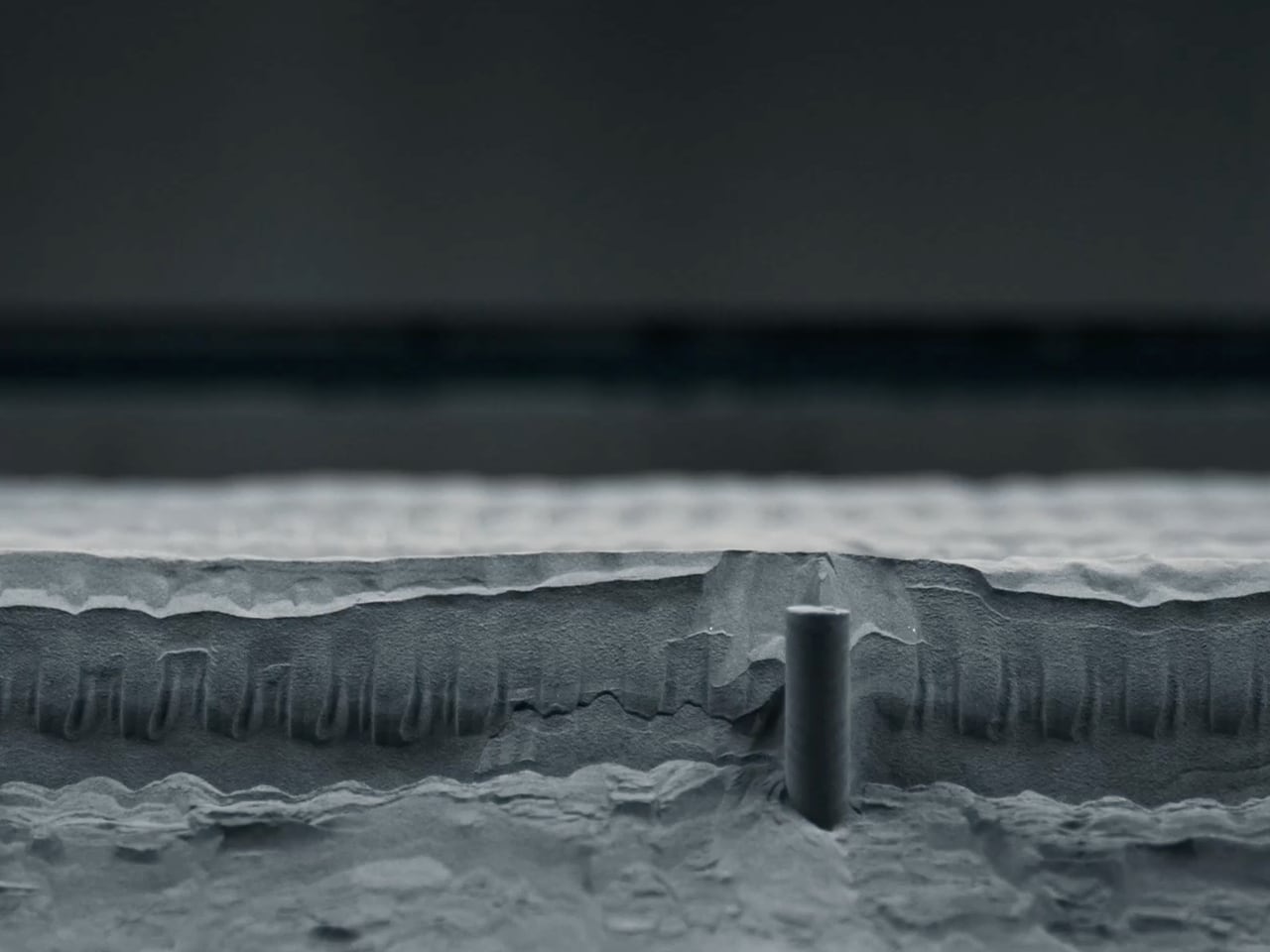

Here’s where it gets interesting beyond just the cool factor. 3D printing lets Apple do things traditional forging can’t. For cellular Apple Watch models, the case needs a plastic-filled split to let the antenna work. How well that plastic bonds to the metal determines water resistance. With 3D printing, Apple can print specific textures on the inner metal surface that dramatically improve that bonding.

Translation: better waterproofing without adding bulk or changing the slim profile. Swimmers, runners in the rain, anyone who lives an active life gets a watch that can handle submersion better than before, and nobody had to compromise on design to make it happen.

That same breakthrough also made the USB-C port on the new iPhone Air possible. They’re using the same recycled titanium powder to 3D-print a port enclosure that’s incredibly thin but still durable. The port design simply wouldn’t work with traditional manufacturing.

The Big Picture

We’ve spent years watching 3D printing go from novelty to genuinely useful technology. We’ve seen it in hospitals printing prosthetics, in space stations printing tools, in garages printing functional parts. But this is different. This is a tech giant taking additive manufacturing and proving it can work at massive consumer electronics scale without sacrificing quality, aesthetics, or performance.

Apple’s not just doing this for environmental PR points, though the sustainability angle is real. All the electricity powering Apple Watch manufacturing comes from renewable sources. The 50 percent reduction in raw titanium means they’re getting two watches from the material that used to make one. It’s all part of their Apple 2030 goal to hit carbon neutrality across their entire operation.

But the real story is what happens when manufacturing efficiency stops being a limitation and starts being a creative tool. When you can print textures in places you couldn’t reach before, when you can use exactly the material you need and nothing more, when you can iterate on designs without massive retooling costs, suddenly constraints become possibilities.

Sarah Chandler, Apple’s VP of Environment and Supply Chain Innovation, said something that stuck with me: “We’re never doing something just to do it once: we’re doing it so it becomes the way the whole system then works.”

That’s the play here. Apple spent over a decade watching 3D printing mature. They tested it at smaller scales in previous products. They solved the titanium powder problem. They figured out the precision tolerances. They built the quality control systems. And now they’re manufacturing millions of watches this way, proving to the entire industry that additive manufacturing can deliver at scale.

For those of us who’ve been following 3D printing from the early days, watching it go mainstream in our homes and workshops, seeing Apple commit to it at this level feels like validation. The technology we’ve been championing? It’s not just for enthusiasts anymore. It’s ready for prime time, empire scale, whatever you want to call it.

And honestly? That’s pretty cool.