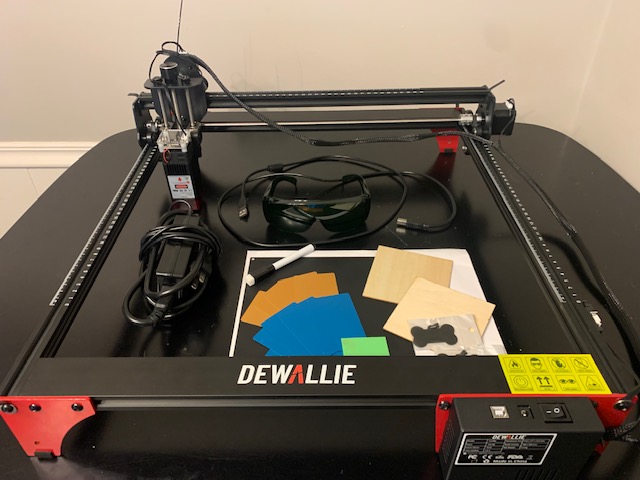

REVIEW – I love crafting! I own a Cricut and it allows me to do most things, with the exception of engraving. I have looked into purchasing an engraving machine because of all the additional options, but never pulled the trigger. When the opportunity came to test out the Dewallie LA-400 Laser Engraving Machine, there was no way I was going to pass that up. Here is how it is going for me.

What is it?

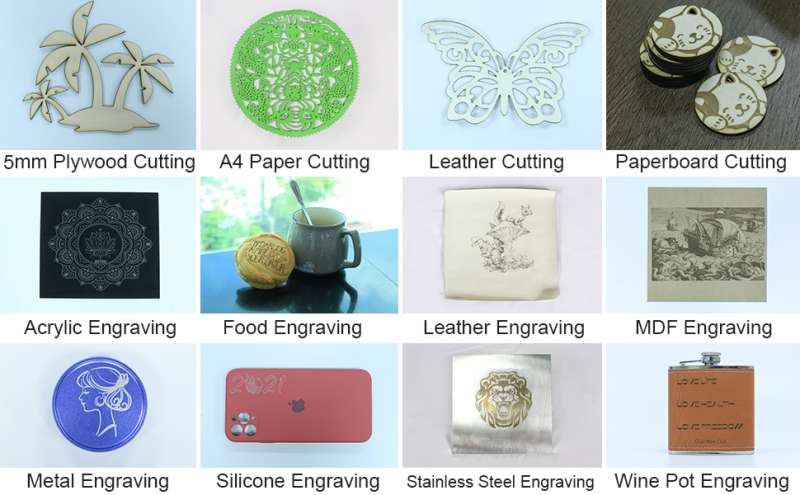

The Dewallie LA-400 Laser Engraving Machine is a compact home desktop engraving machine. This machine can laser engrave and cut graphics and images on materials like wood, paper, leather, acrylic, and more.

Hardware specs

Model: LA 400

Laser power: LA-2: 5 W

Engraving size: 400 x 400 mm

Precision: .01 mm

Wavelength: 445±5nm

Product weight: 4.4 kg

Product dimension: 616 x 577 x 212 mm

Focal Spot: 0.08-0.1mm

Input Volt/Current: 12V/1.7A

Module Power: 4500~5500mW

Fan speed: 8000RPM

Data transmission method: USB connection

Supported cutting materials: cardboard, non-woven, thin sheet, acrylic material, certain thin plastic sheets

Supported engraving materials: paper, cardboard, plastic, PCB board, aluminum oxide, non-reflective plating surface, lacquer, white surface

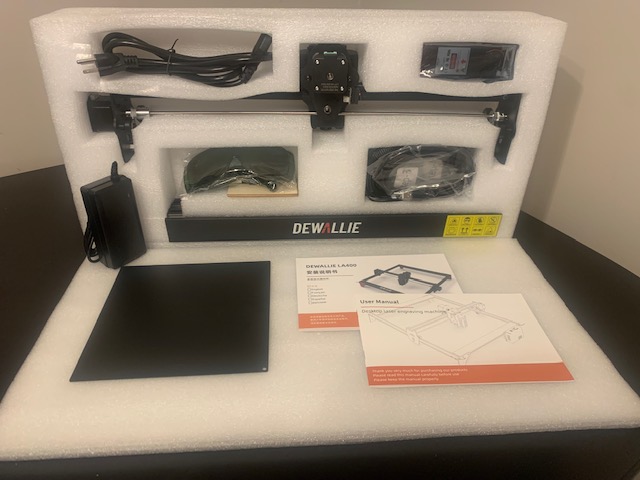

What’s in the box?

I do appreciate a nicely packaged product and when this product arrived, it did not disappoint. Not only was it shipped in a box inside a box, each piece was nicely placed in a Styrofoam protective insert, which assured that all the pieces were protected in transit.

- Sides: 2040 Profile x2, 2020 Profile x2

- Cantilever

- Main Control Box

- LA-2 Laser Head

- Set of switches

- Hexagon socket countersunk head screws: M3x8 (3)

- Spherical head screws: M5x6 (4), M5x16 (8)

- Cylindrical head screws: M3x6 (2), M5x20 (8)

- Cable ties x 5

- Legs x 3

- Gasket x 4

- Belt x 2

- Assembly tools

- Power Cord & Adapter

- USB data cable

- Protective glasses

- Assembly manual

- User manual

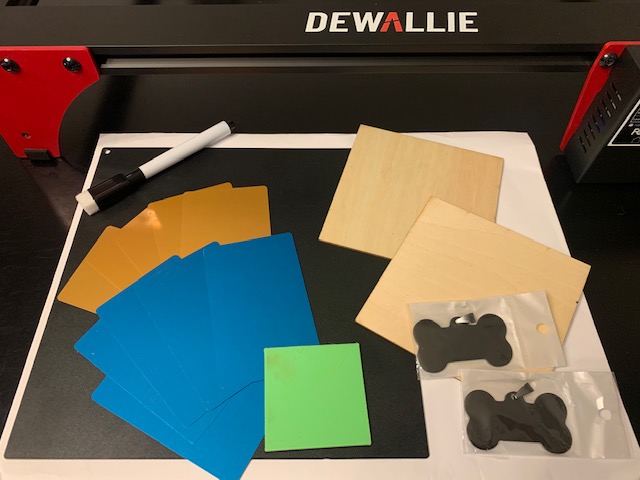

Also included with the Dewallie LA400 is a variety of materials to practice your engraving and cutting.

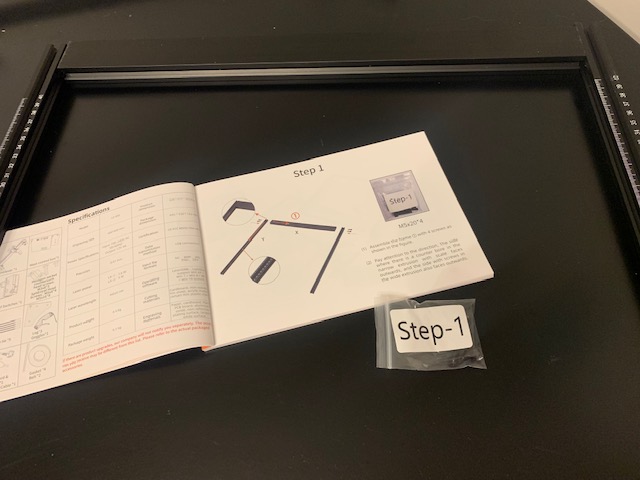

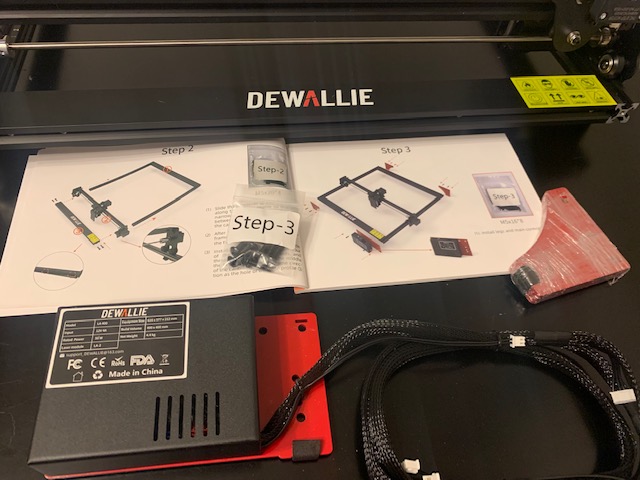

Assembly

There is a step-by-step guide to assembling the Dewallie LA400 Laser Engraving Machine included with the machine. The manual is written in six different languages and although I appreciate this, I feel like it was lacking in all the details and visuals that I needed to successfully put it together without questions. Because of this and the fact that I made some mistakes and had to reassemble, I wanted to highlight some of the things to pay attention to when putting your machine together.

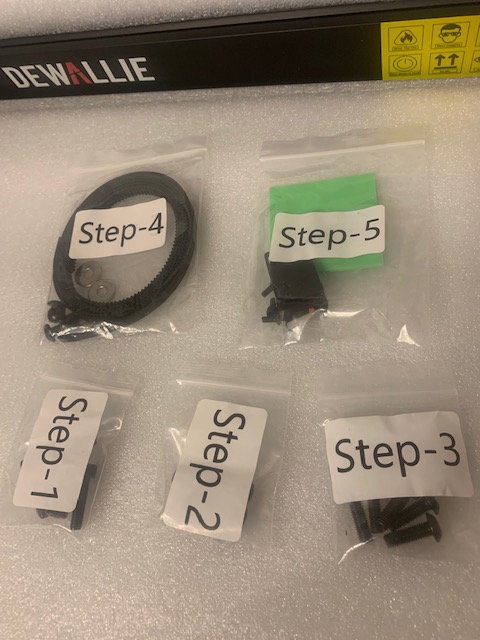

I must mention, that I appreciated that the corresponding parts needed to assemble for each step of the process were separated and labeled. This was very helpful when it came to putting the machine together.

Step #1: Assembling the frame

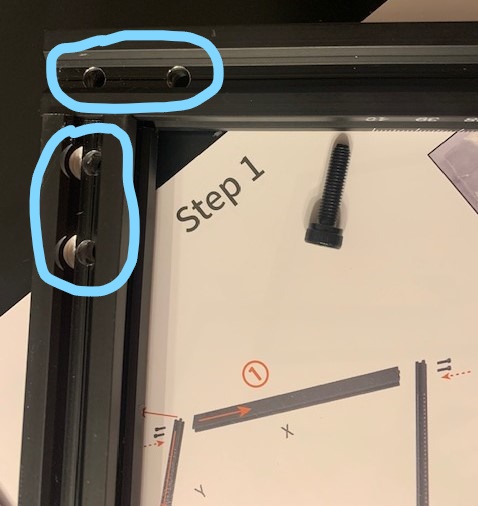

Make sure to pay attention to the direction you are placing each piece. The main trick to this step is making sure that you are using the side that has the wide screws holes on the outside. See below pictures.

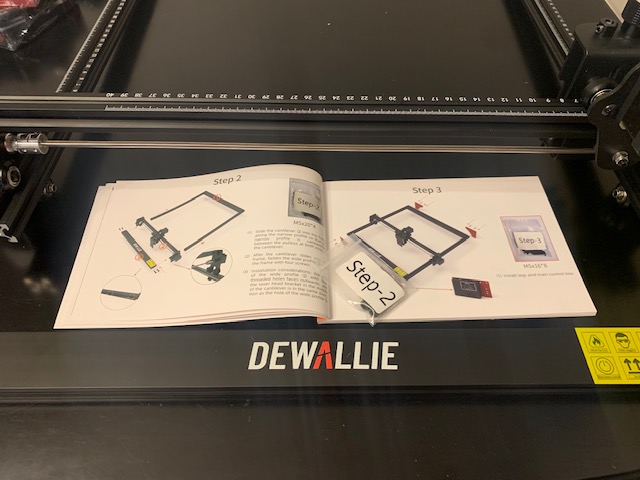

Step #2: Sliding on the cantilever and adding the remaining side (“Dewallie” piece)

Make sure that the laser head bracket on the cantilever is facing the “Dewallie” piece. If you see, this was were I made my mistake!

Step #3: Install the legs and the main control box

I found screwing on the control box leg a little awkward, with the other three being simple. It was hard for me to get the leverage to tighten in the screws. In order to get a better angle, I liked to tip the frame up which kept causing the cantilever to roll back.

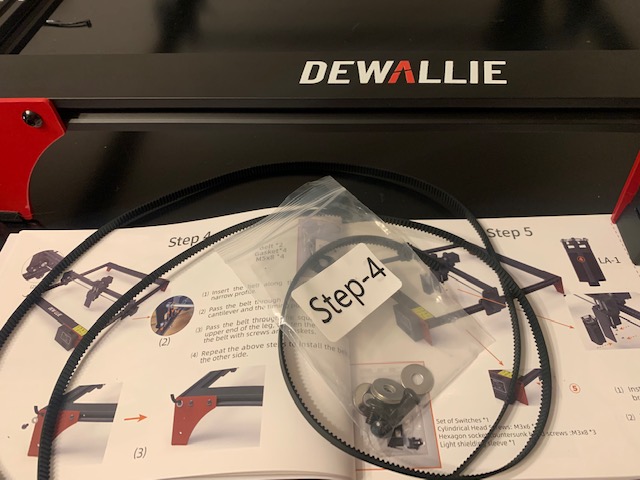

Step #4: Inserting the belts

This was by far the trickiest step. If you can find someone to help you with step, it will make a big difference. This is where you will find out how well you lined up your legs in step #3. You must pass the belt through the square hole in the leg, line the belt up along the guard rail and then pass the belt through the two pulleys of the cantilever and timing pully. Be patient and have someone help on this step if possible.

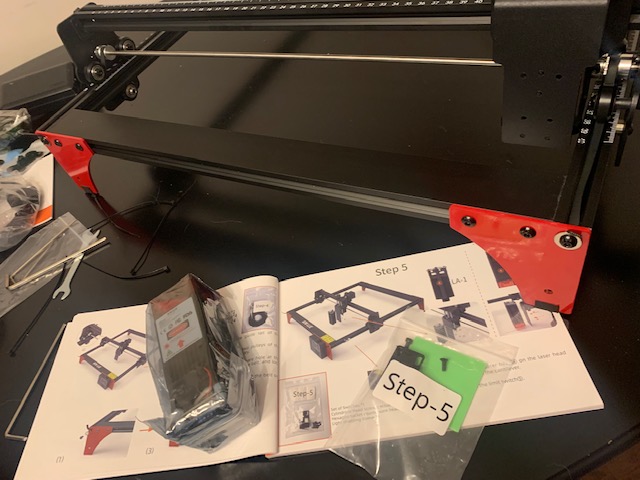

Step #5: Install switch and laser head

As you can see, I still hadn’t figured out that my cantilever was backward here. This was the step that I caught my mistake! This was also a tricky step in getting all the little screws in as you attach the laser head. What threw me off the most was that the holes didn’t match up, as you can see. So it took me a few minutes to figure out which holes I needed to use to attach the laser head to the laser head bracket.

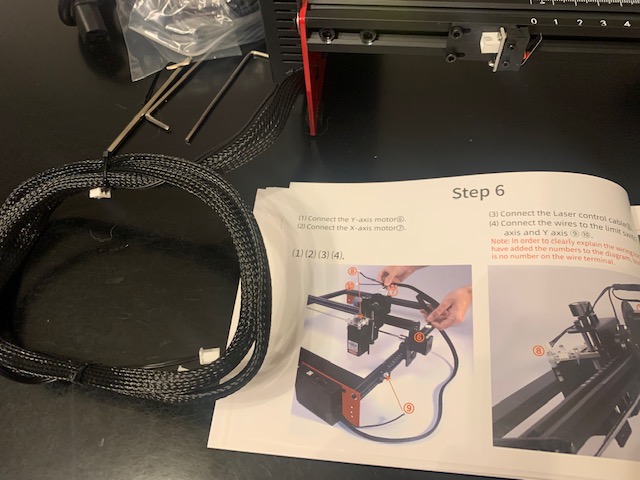

Step #6: Connecting the cables

The manual does a great job showing this step on where to connect which wires on the machine. Finally, you connect your cable ties as described and you should be ready to rock and roll!

After installing the software and attempting to use the Dewallie LA-400 Laser Engraving Machine, I could not get it to move. I did troubleshoot with my contact at Madethebest and still it would connect to the software, but would not go anywhere. I tried everything from reinstalling the software, loosening and tightening the belts, rechecking the wires, etc. In the end, it was the third time that I unhooked all of the control cables and reconnected them that it started working. I can’t tell you what I did wrong, but I guess I finally got it right and it has worked ever since.

Operating Software

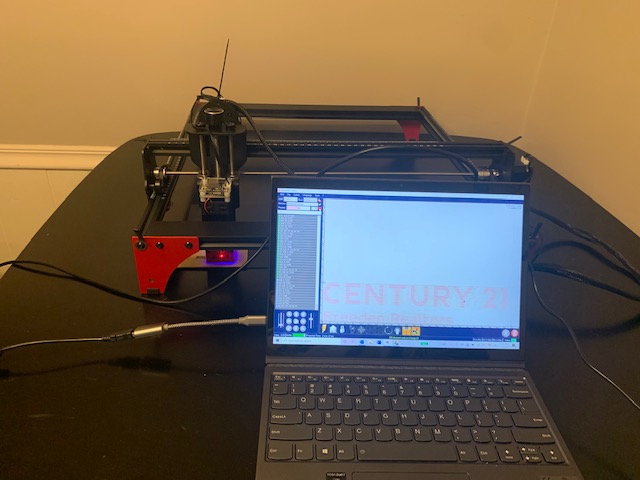

The Dewallie LA-400 Laser Engraving Machine supports the most popular operating software LaserGRBL and LightBurn.

LaserGRBL is a very popular and free software that supports Win XP, Win 7, Win 8, XP, Win 10 systems. You will need to download the software from the website following the prompts listed in the Dewallie user manual. Another operating software option is LightBurn. LightBurn is good to use for Mac users and also supports Windows. The LightBurn software is a paid service, but you can get a free 30 day trial to see if this would be something that would be worth it for you and your needs. For my review purposes, I focused all my efforts on learning and using the LaserGRBL software.

Note: With whichever operating software you use, your machine receives its commands from the computer, so make sure that it always stays connected during usage.

Design and features

I would like to start by telling you that you need to be prepared for fumes, smoke and non-pleasant smells. It is a laser engraver, which means the laser is burning the material to create the engraving. So you will want to make sure you use in a well-ventilated area. There are a lot of creative folks that have created ventilation boxes for their machines to help with this that you may consider, but unfortunately that is the reality of a laser engraver.

One of the most important steps in using your Dewallie LA-400 Laser Engraving Machine is making sure that your laser is focused and positioned correctly. The Dewallie LA-400 makes this simple and easy. It has a fixed-focus laser, with a specific focus position located 2mm from the bottom of the light shielding sleeve.

A 2mm positioning block is included in the package to use to make sure that you can easily adjust the laser to that magic 2mm height. Simple move the laser head above the object you wish to engrave or cut using the adjustment knob on top of the laser head bracket. Place the 2mm positioning block on the object to be engraved or cut. Turn the adjustment knob until the light shielding sleeve contacts the positioning block. Slide out the positioning block and begin.

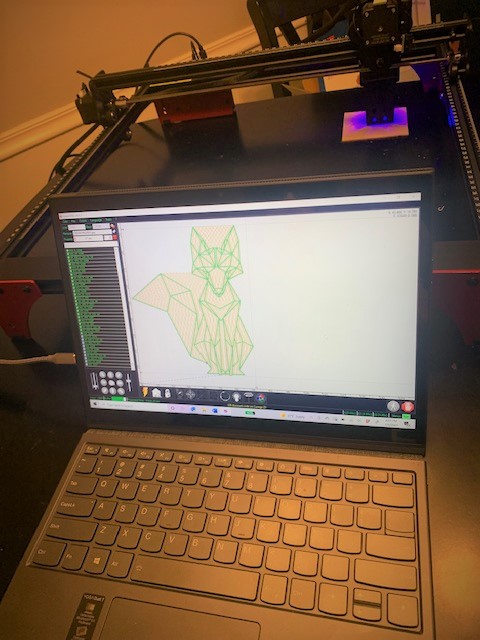

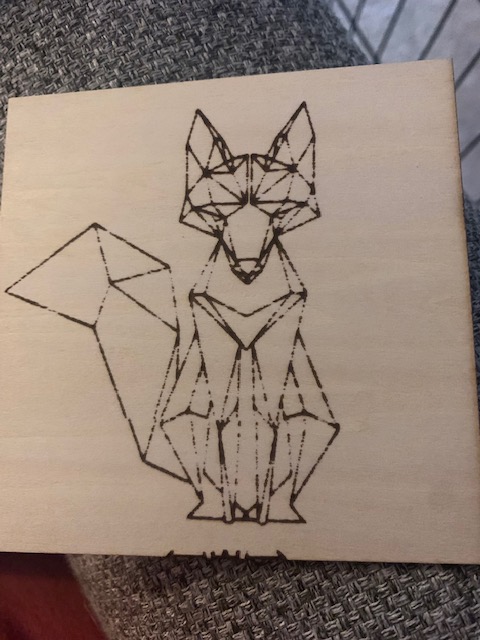

After adjusting the height of the laser, I began with my first attempt at engraving. It was this fox design image my daughter found on the internet. I just kind of winged this one, making sure that the image would fit on my material and just went with it. I didn’t pay much attention to all the options of speed and power.

To my amazement, it actually didn’t turn out too bad. The image quality wasn’t super great and like I said I didn’t mess with all the settings and hadn’t done a lot of research on the LaserGRBL software at this point.

I decided that I then wanted to try the cutting function. Again without doing a lot of research on the LaserGRBL software at this point. I did know that I needed to change the settings to cut vs engrave and that it needed multiple passes. So, I used the logo on my computer for my real estate brokerage.

As an engraving on the first pass, it looked great. The second pass got darker. By the third pass, it was burnt looking, but as you can see it did go thru the material. After researching, I had the parameters for the laser set wrong for what I was trying to accomplish.

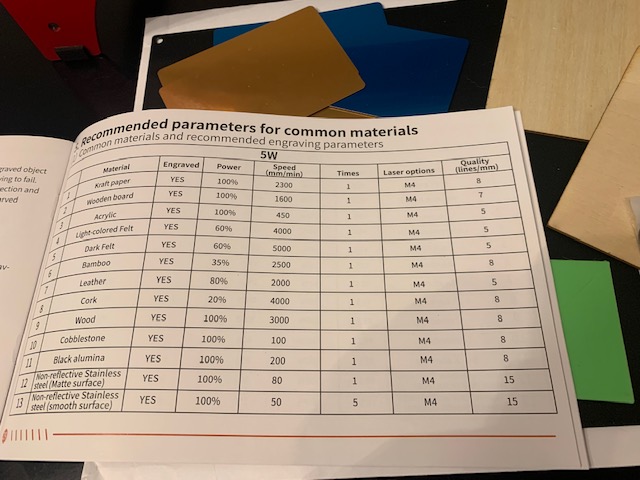

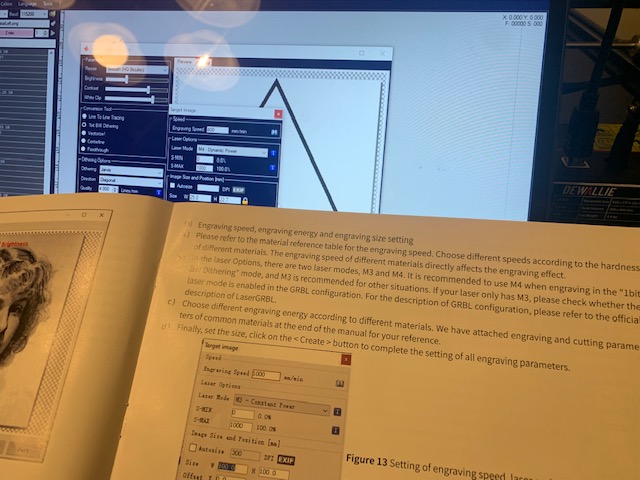

The user manual that comes with the Dewallie LA-400 Laser Engraving Machine does have a section in the back for common materials and their parameter recommendations. As you can see, it will tell you what percentage of power, speed and how many passes (times) for each material. This is definitely a great resource when figuring out how to use your machine.

Finally, after really digging into different online resources, LaserGRBL FAQ and especially reading and following the LaserGRBL Community Facebook group, I learned a whole lot of tips and tricks to using the software and about laser engraving machines (as this group is for the software and not specifically for the Dewallie LA-400) in general.

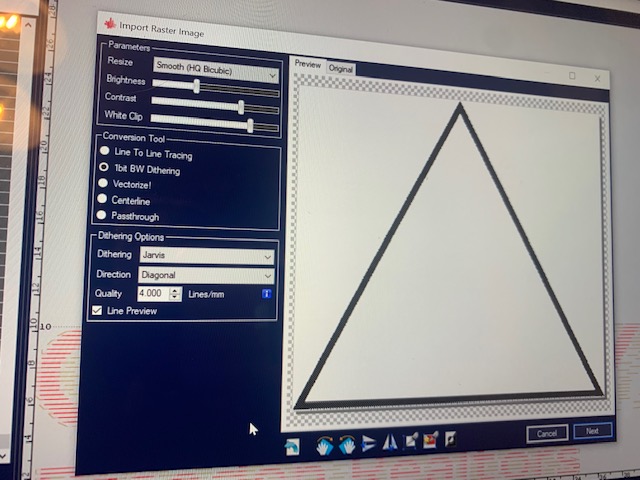

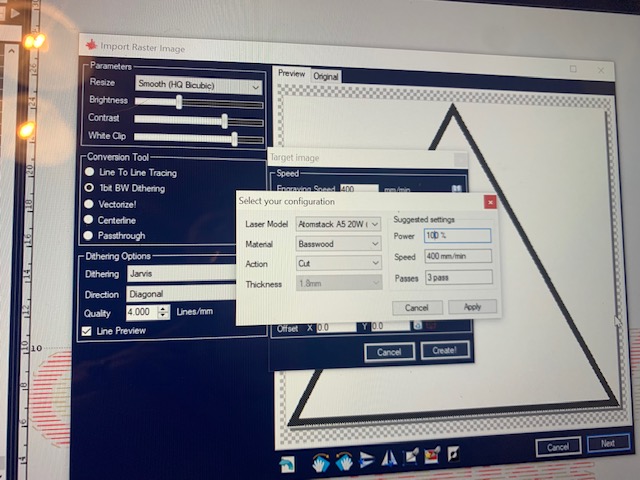

I decided next to just cut a simple triangle.

According to the LaserGRBL Community Facebook group, one of the members mentioned that 1bit BW Dithering mode might be a better fix for cutting. He preferred the Jarvis and Diagonal on the options in this mode, so I just went with that.

Next for the configuration, it recommends 400mm speed, 100% power and 3 passes.

The user manual that comes with the Dewallie LA-400 Laser Engraving Machine does mention when choosing the “1bit BW Dithering” mode- that you will want to choose the M3 laser mode. All other situations, you would always use the M4 laser mode option.

Here is the triangle. It popped right out. Looks a little rough, since I kept using the same practice material, but overall I do believe I’m finally starting to understand and love the Dewallie LA-400.

I wanted to show you a few other materials and more successful projects as well.

Here is a metallic dog tag I made for my furbaby, Libby.

Lastly, I thought I would show you a little example about how switching a few parameters can change the whole look of the final product.

There is still a lot of learning to be done for me to be a confident laser engraver, including mastering the LaserGRBL software and configuring my Dewallie LA-400 Laser Engraving Machine to the right perimeters depending on materials and design. So far, I’m happy with my Dewallie LA-400 and I’m excited to keep learning and loving the machine and all it can do!

See it in action

What I like

- Sharp detailed engraving and cutting

- Sturdy and well made

What I’d change

- More detailed assembly instructions in the manual

- Consider close up visuals

- Consider including more practice materials

Love the idea of a laser engraving machine, but only for smaller jobs? Check out my fellow reviewer Julie’s review of the smaller option of the Dewallie Mini Portable Laser Engraving Machine.

Final thoughts

I still have a lot to learn on using the operating software, selecting the correct parameters for materials and just laser engraving machines in general. However, with the help of the LaserGRBL Community Facebook group, practice and the use of trial and error, I do believe that I’m going to enjoy using the Dewallie LA-400 Laser Engraving Machine. Overall, I am excited to welcome the Dewallie LA-400 to my crafting world!

Price: $299.99

Where to buy: Madethebest and Dewallie (Save $10 for any order over $99- Coupon: gadgeteer on both websites)

Source: The sample for this review was provided by Madethebest.