REVIEW – I’ve been able to review a few laser engravers/cutters for The Gadgeteer. I have come to enjoy the benefits of owning and using a laser engraver/cutter to make gifts, and projects for paying customers, and just using it as a hobbyist. Previous machines have been “open-framed” laser engravers. This means the smoke and fumes from the laser doing its thing are just released into my workshop. I have to use a shop vac to suck up most of the fumes and move them outside—a very noisy and cumbersome process. The Creality Falcon2 Pro 40W Laser Engraver is an enclosed machine. It includes an attached “hood” that captures all the fumes and vents them through a tube to the outside world—keeping my shop and my lungs very clean and happy.

↓ Jump to summary (pros/cons)

Price: $1,899.00

Where to buy: Creality and Amazon

What is it?

The Creality Falcon2 Pro 40W Laser Engraver is a full-featured, powerful, enclosed laser engraving and cutting machine. Creality, well known for its many superb 3D printers, has entered the laser engraver field with a few well-made and full-featured offerings. This model, the Falcon2 Pro, is their flagship model. They also offer an even more powerful 60W version of this model.

This Falcon2 Pro is equipped with a powerful 40W laser, that can easily engrave and cut through a wide range of materials, including wood, paper, acrylic, leather, and even some metals. The machine offers high-resolution engraving capabilities with a fine spot size of 0.08mm (0.06mm with the included 1.6W laser module), ensuring detailed and sharp results. Its large working area of 400 x 415 mm (15.75×16.34 in.) provides enough room for both small and medium-sized projects.

The Falcon2 Pro supports software like LightBurn (free trial and then paid license) and LaserGRBL (free), making it user-friendly for both beginners and experienced users. It also includes numerous safety features such as an automatic shut-off in case of overheating, fire, excessive tilt, and a dirty laser lens. The laser light filtering enclosure traps exhaust and the built-in fan moves the exhaust outside.

What’s included?

- Falcon2 Pro Aluminum Frame and Gantry

- Crumb Tray

- Aluminum Slats

- 40W Laser Module

- 1.6W Laser Module

- Exhaust Frame and Laser Light Filtering Plastics

- Exhaust Fan and Vent tubing

- Light Panel

- Air Assist pump and tubing

- Laser Goggles

- Power Supply

- Focus Block

- Hardware and Tools

- USB A to USB C cable and Adapters

- Memory card

- Security Keys

- Sample materials

- Camera Calibration Card

- User Manual

- Stickers

Tech specs

- 40W Diode Laser Module (with 22W Precise mode)

- 1.6X Diode Laser Module included

- Focusing: Manual

- Speed: Up To 25,000 mm/min

- Laser Wavelength: 455+5nm

- Engraving area: 400×415 mm (15.75×16.34 in.)

- Exhaust hood, fan, and tubing

- FDA Class 1 Safety Certification

- Triple mode monitoring: Airflow, Fire and Lens

- Built-in Camera

- Built-in Light Bar

- Laser Engraving Software: LightBurn, LaserGRBL

- Supported Materials: Cardboard, wood, bamboo, rubber, leather, fabric, acrylic, plastic, etc.

- Supported File Formats: jpeg/jpg, png, bmp, svg, dxf, etc.

- Product Size: 664x570x328.4 mm (26.1×22.4×12.9 in)

- Product Weight: 18.56kg (41 lb)

- Power requirements: 100-240v

- Operating Temperature: 5º-35º C (59º-95º F)

- Operating System: Windows /MacOS

- Certifications: EC60825, FDA, CE, ROHS, FCC, UKCA, UL Report, PSE

Design and features

The Creality Falcon2 Pro is a very full-featured machine. There are many features to cover in this review, and I hope to give a good account of my experience with it. The team at Creality needs to be given kudos for a very well-thought-out and intuitively designed machine.

Construction

The construction of the Falcon2 Pro is top-notch. The majority of the machine is powder-coated aluminum. All of the connections (power, computer cables, air hose, etc.) are located on the left and right sides of the machine. This keeps the cables and such out of the way and secure. There’s nothing more frustrating than bumping the USB-C cable going to the computer midway through an engraving job. Having the cables on the side eliminates that headache.

The front of the Falcon2 Pro has a simple set of buttons for moving the laser module to the home position (front-left) and arrow keys for moving the laser module in all four directions a few millimeters at a time. The machine has a set of safety keys that are needed to be used to turn the machine on. There’s also an emergency-stop button for times when a job gets out of control (i.e. fire). Laser engraving and cutting are accomplished by burning, so fire is a possibility. See more on that below.

Exhaust Hood

As mentioned before, the best feature of the Falcon2 Pro (in my opinion), both visually and usability, is the distinctive red exhaust hood. The red plastic filters out the harmful aspects of the blue diode laser light emitted by the laser modules. The exhaust hood traps all the fumes and smoke of engraving, especially cutting, and vents them out the side through the exhaust hose to the outside world. I did find the exhaust enclosure did leak a little bit, but as a whole, it captures and exhausts the fumes and smoke adequately.

The exhaust hood has a sliding door that is opened to access the material being used and that has to be closed for a job to be started. If the door is opened while the laser module is working, the machine will pause the job until it is closed again. This is another great safety feature that Creality has put into the Falcon2 Pro.

Crumb Tray

The very bottom of the machine has a large sliding “crumb tray” to catch any small pieces that are cut out of the material. The tray also acts as a barrier between the laser and the table or desk you have the Falcon2 Pro sitting on. Just like the sliding door in the exhaust hood, if you open the crumb tray during an engraving or cutting job, the machine will stop working until the tray is closed back up.

Laser Modules

The Falcon2 Pro comes with two different laser modules. The larger 40-watt laser module is what would be used mostly. It can engrave and cut a wide host of materials, such as cardboard, wood, bamboo, rubber, leather, fabric, acrylic, plastic, etc. It can also engrave stainless steel, which I found quite exciting. Stainless steel produces colors you would not expect when exposed to certain laser powers and various speeds of the laser module’s movement. The 40-watt module can be into what is called “Precise” mode which reduces the maximum power to 22 watts and makes the laser spot smaller and more detailed when engraving.

The Falcon2 Pro 40-watt package also comes with a smaller, less powerful 1.6-watt laser module. This laser can be used to produce engravings that are finer detail. The laser spot on the 40-watt is, at its smallest, 0.08mm, and the 1.6-watt laser’s spot is much smaller. Both laser modules attach to the Falcon2 Pro’s gantry arm with a slide-in mounting bracket.

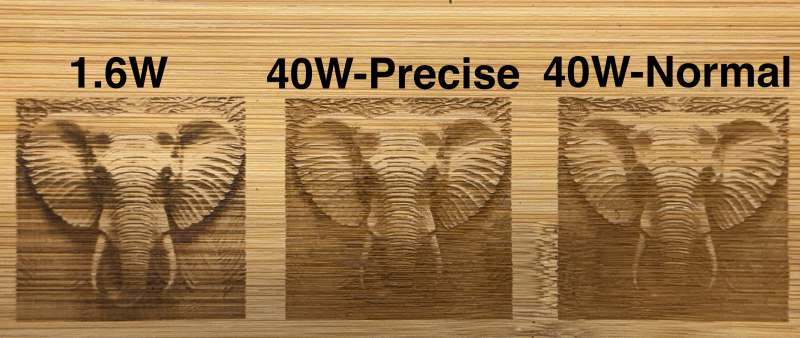

This picture shows a comparison between the 1.6-watt and the two modes of the 40-watt laser module. As you can see, the 1.6-watt laser module produces a sharper, more defined engraving. While the 40-watt in “precise” mode does a good job also, the “normal” mode seems less detailed and blurry. (The grainy look of the engravings was caused by the bamboo material I used for this test.)

One missing feature of the Falcon2 Pro I would like to have been included is an auto-focus of the laser module, especially the 40-watt laser module. Creality includes a small focusing bar that has to be used manually to make sure the laser is at the optimal distance from the material to engrave or cut perfectly. Auto-focus would make the Falcon2 Pro cost more, so maybe a future Falcon model would include it.

Air Assist

The Falcon2 Pro includes an external, quiet air-assist pump, which is great. The air pressure is dialed in via a knob on the side of the machine. When engraving, you may not want as much soot from the engraving being blown onto the top surface of your material. However, when cutting, air assist is required to aid in the cutting process and keep the material free of soot, which is produced in abundance.

Camera

The Falcon2 Pro includes a very nice built-in camera inside the exhaust hood. The camera makes the placement of artwork a more precise endeavor. Calibrating the camera inside of LightBurn was quite the lesson in frustration. Maybe it was just me, but it took me three runs through the calibration wizard before it was performing to my liking.

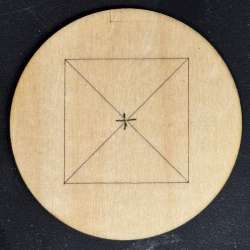

The first test I did was to randomly place a circle of wood with a little plus sign on it onto the Falcon2 Pro’s engraving bed. LightBurn then takes a picture of the Falcon2 Pro’s engraving bed so you move the artwork over the material in the picture. If the camera is calibrated and aligned properly, then the machine will engrave (or cut) the material precisely. My test was successful, although not perfect. You can see in the image above that the image I drew and placed in LightBurn is almost engraved on the little mark I made on my material. It’s about a half of a centimeter off. That may not seem like much, but could throw off an engraving on an expensive piece of material, and ruin it.

Laser placement before starting a job is crucial in most cases. What other laser engravers I have used included a crosshair laser attached to the side of the laser module. This gives very precise placement of the laser to begin the job precisely. The camera is good for almost precise placement, but I don’t think laser alignment with a camera is the best. I have since added a laser crosshair to my Falcon2 Pro’s 40-watt laser module. It was a very simple and inexpensive process to add it. This makes my Falcon2 Pro much better in my opinion.

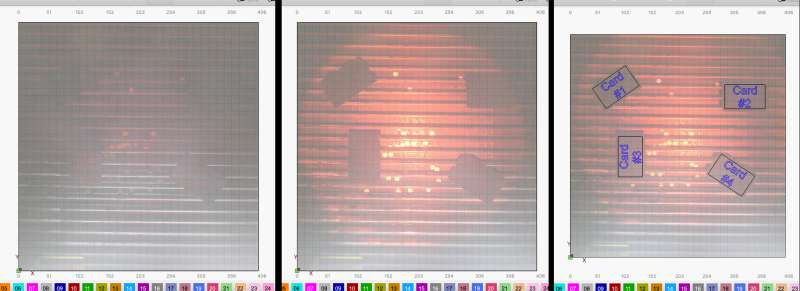

Here is another example of using the camera to place artwork at various locations around the engraving bed. As you can see the result is off on a few of the engravings, whereas on the screen, the artwork was placed as close as possible to where I needed it to be. Also, the internal light bar at the front of the laser frame does not throw enough light to see a dark-colored item to be engraved. I had to use a flashlight to put more light into the machine for the camera to pick up the little aluminum cards.

Engraving and Cutting

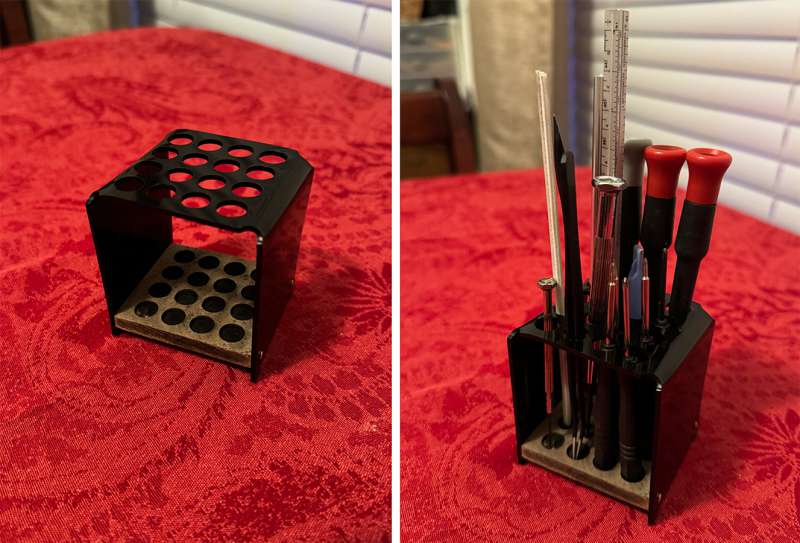

Engraving and cutting are the real reasons anyone would want a laser machine. As expected, the Falcon2 Pro engraves very quickly and with great detail. Cutting is fast and very powerful. These are a few things I made while testing the Falcon2 Pro over the time I’ve had it so far.

One thing a more powerful laser module like the 40-watt of the Falcon2 Pro is the ability to engrave stainless steel, which produces some amazing results. Each color is achieved by the power level and speed of moving the laser module. (The last row of colors is crooked because I accidentally bumped the table. Oops!)

Safety

The Falcon2 Pro has several safety features built into it. First and foremost is the red laser-light filtering plastics used in the exhaust hood. You can safely watch the engraving or cutting job as it progresses without any worry of zapping eyeballs. Believe me, you don’t want those yellow splotches in your vision from exposed blue diode laser light.

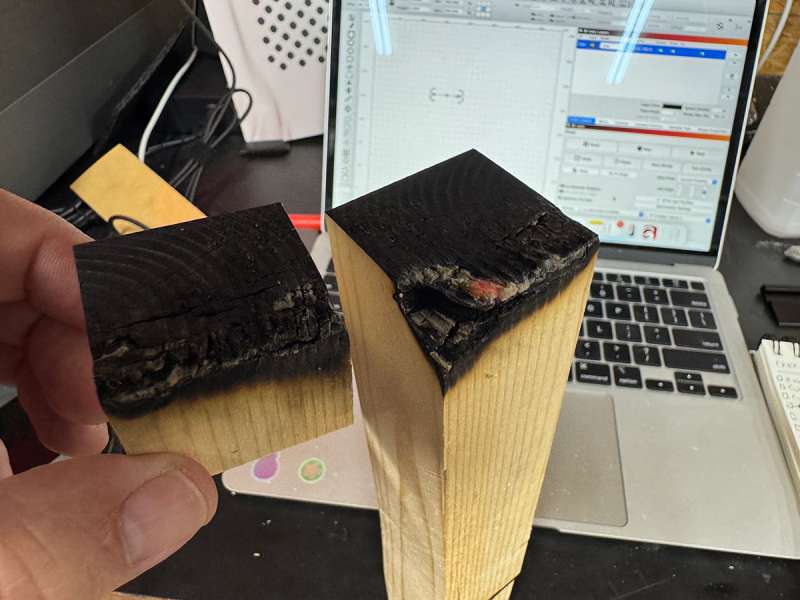

The Falcon2 Pro also monitors for fire while it is running. Some wood will burn from cutting at a slow speed and at top-most power settings. I tested this feature by trying to cut through some 1.5-inch (38 mm) wood in a single pass. The wood did catch fire slightly, and the Falcon2 Pro shut off and sounded an alarm. Nice safety feature that worked quite well.

The Falcon2 Pro also monitors the 40-watt laser module’s lens to be clean. When it detects the lens needs to be cleaned, the machine will not start a job until it has been cleaned and the alarm reset. This alarm sounded a few times during my testing, especially after engraving some rubber-stamp material to make a funny Bluey stamp for my granddaughter.

As noted earlier, the control panel on the front of the machine has an emergency stop button to make it easy to shut off the machine quickly. This is a common feature of laser engravers.

The Falcon2 Pro also has a feature to shut off the engraver if it tilts to an extreme angle. I guess this is to prevent the machine from falling off a table if someone trips on the power cord. I didn’t test that safety feature.

Assembly, Installation, Setup

The Creality Falcon2 Pro comes very well packaged and surprisingly, mostly assembled. The main frame and laser module gantry all come pre-assembled and perfectly square from the factory. The belts were all just right for the smooth movements of the laser module.

The distinguishing feature of the Falcon2 Pro is the red exhaust hood. The hood is what took 90% of the time in getting the Falcon2 Pro ready to use. The exhaust hood consists of five pieces of sturdy aluminum frame and four pieces of red, laser-light filtering, plastic. Two of the pieces of plastic are thick and used for the sides, with one having the exhaust fan pre-installed in it.

The part of the assembly that took the longest for me was sliding the very thin pieces of the exhaust hood cover into the frame pieces. The two pieces of cover plastic are very thin and floppy. Getting the plastic to line up properly and slide into the frame smoothly took quite a bit of effort and time. Once it was completed, the cover and sliding access door worked very well. The exhaust fan has a long wire to hook it up to the Falcon2 Pro’s controller at the very front of the bottom frame.

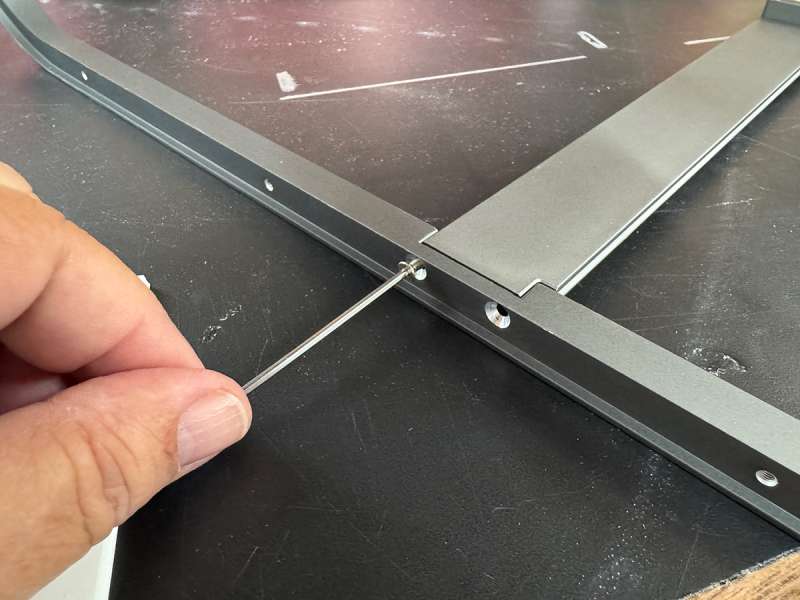

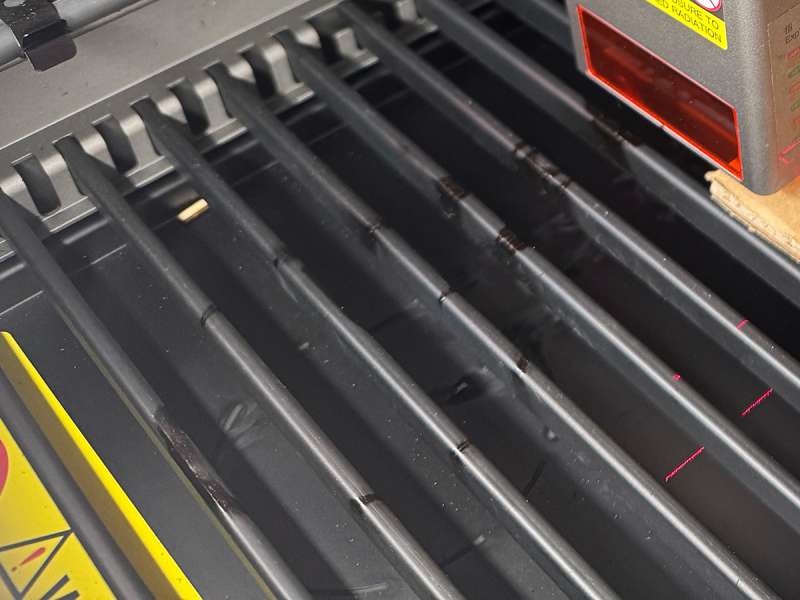

The Falcon2 Pro comes with an engraving bed of sorts made up of 25 aluminum bars that fit into slots in the bottom frame rails. This bed is needed to give the material being used, a place to rest while engraving or cutting. Small pieces that are cut fall into the “crumb tray” at the very bottom of the machine. The crumb tray slides out the front of the machine like a drawer and allows you to collect the small pieces without having to do any disassembly of the engraving bed.

Once everything is assembled and hooked up, the machine is ready to be discovered by the chosen software. I use LightBurn with my engravers, so I used it for all my tests of the Falcon2 Pro. Lightburn has a free trial and then you need to buy a yearly license for $60.00 USD. Yearly license renewals are $30.00 USD. I think it is well worth the cost. LightBurn discovered the Falcon2 Pro and I was ready to go.

One great feature of the Falcon2 Pro is the built-in downward-facing camera. As stated before, the camera needs to be calibrated using the software of choice along with a calibration card included with the Falcon2 Pro. This was somewhat difficult (at least for me), but I eventually got it working as discussed above.

Final thoughts

The Creality Falcon2 Pro 40W Laser Engraver is a great product and I highly recommend it. It is by far, the best laser engraver I have owned. It has all the great features that make owning a laser engraver a valuable addition to any hobbyist’s toolbox. The Creality Falcon2 Pro line of laser engravers would be a great addition to someone wanting to make some money on the side by offering a laser engraving service or making products to sell.

What I like about the Creality Falcon2 Pro 40W laser engraver

- Powerful and Fast

- Smaller, very precise laser module included

- Enclosed with exhaust fan

- Crumb tray and bed included

- Worked perfectly with LightBurn

- Camera positioning of artwork is good, but not perfect

What needs to be improved?

- Exhaust Hood Assembly is a bit tedious and finicky

- Auto-focus would be a nice future enhancement

- Crosshairs on the laser module would be a great addition

- Enclosure leaks a little

Price: $1,899.00

Where to buy: Creality and Amazon

Source: The sample of this product was provided for free by Creality. Creality did not have a final say on the review and did not preview the review before it was published.

Gadgeteer Comment Policy - Please read before commenting

@Julie

I just wanted to let you know that I really like the new format of “What I like,” “What needs to be improved?” and “Price, …”

sections of the reviews.

Thanks Ruud! We’re working to make some useful but subtle improvements on the site 🙂