REVIEW – My foray into the world of modern handheld heat presses was many years ago now, when I bought the original Cricut EasyPress. I mostly used it for pressing the occasional vinyl project. When I started experimenting with sublimation, I quickly abandoned my EasyPress for a much more robust lever press from Heat Press Nation (HPN).

⬇︎ Jump to summary (pros/cons)

Regular Price: $129.99

Deal Price: $89.99

You Save: $40.00

Where to buy: Amazon

While my HPN press is very good, it’s also large, and the 12×15″ platen takes a whopping twenty minutes to heat to 360° F from room temperature (60° F in my basement this time of year). A hand press, by comparison, is smaller, so it preheats faster – and uses less energy in the process.

I haven’t used a hand press much since I purchased my HPN press, and I was interested to see how well a more capable hand press might perform with what I do most: sublimation.

So how well does the HTVRONT H10 heat press stack up to a swing-arm standard heat press? And how good is it as a heat press in general? Let’s find out!

What is it?

The HTVRONT H10 is a handheld 12×10″ heat press.

What’s included?

This heat press only includes the base tray for safe storage and preheating. No additional accessories are included.

I really wish HTVRONT included a silicone press mat with this heat press. It’s an inexpensive accessory and an absolute must when using any hand press. These mats can be readily found on Amazon and elsewhere for around $15, and a single mat should last you years, provided you maintain it.

Design and features

Handheld heat presses are a class of heat press which rely on gravity and human leverage to apply pressure for the purpose of making a project with something heat-set.

HTVRONT’s offering is pretty distinct from the competition, because it includes a novel feature: realtime pressure feedback. Instead of endlessly guessing and trying to feel the best pressure for a given project, this heat press shows the pressure applied by the device at all times while it’s in use. This is great, as applying too much pressure really wears out your body, and applying inadequate pressure results in failed projects and wasted materials.

Another feature of this heat press is pretty unique: it’s maneuvered using two handles, instead of the standard single-handled EasyPress design. This makes it much easier to apply even pressure across the entire 12×10″ platen.

The large segmented, illuminated display shows the time, temperature, and pounds of pressure, making it easy to see all the information you need for success.

The included plastic tray is designed to safely hold the heat press between uses. Because this heat press is capable of up to 400° F, it’s very important to always make sure your work area has enough room for the tray and a press mat, so you can safely stow the press immediately after use.

Basic usage

The controls are very straightforward, and mimic the layout and icons of HTVRONT’s other heat press products. Time and temperature buttons make it easy to set both, and the big R button is used to exit settings (although these will also time out automatically) and start the timer. This button is red while the press is preheating, then it turns green when fully heated.

Pressing and holding the temperature button toggles the temperature display between Celsius and Fahrenheit; pressing and holding the time button toggles the pressure display between pounds and kilograms.

This type of press can be used for all sorts of fun, creative projects, including:

- DTF transfers

- Heat-activated vinyl (HTV)

- Laser-cut pleather patches

- Iron-on embellishments

In other words, anything with a heat-set adhesive performs great with the H10. It’s a solid heat press that’s easy to use, and the instant pressure feedback makes it very easy to achieve consistent results.

Importantly, unlike my HPN press, the H10 reaches 320° F in just under four minutes. This is much faster than my HPN press, making it a much better option for quick, small projects.

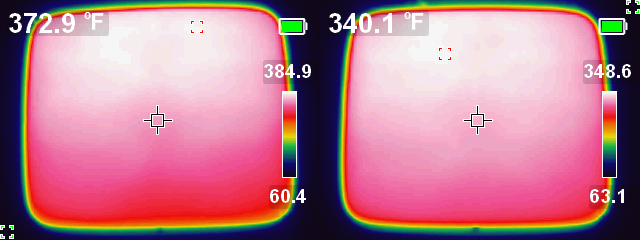

I will note that, like pretty much every consumer heat press, the margin of error on the temperature display is rather large. I recommend using some sort of temperature device to figure out the specific adjustment for maximum accuracy with whatever heat press you choose. I prefer to use a thermal camera for reviews, since it makes it very easy to show the heat distribution of the whole platen. Other options, like an IR thermometer or a thermocouple, also work.

My tests were all performed before I looked at the real temperature of the platen, so I made no adjustments. These images show the platen set to 400° F, then 355° F.

So… what about sublimation?

Will it sublimate?

Sublimation is molecular magic which requires two important factors: heat and pressure. Inadequate heat means the ink doesn’t sublimate; inadequate pressure means it doesn’t fully bond to the target substrate.

Not all substrates are equal, and some are far more amenable to pressing with a hand press than others. You will always get much better results by applying your own force to the press while it’s running, but there’s a slight problem with this: sublimation ink is toxic, and it’s a really bad idea to have your face directly above a heat press while it’s pressing a sublimation project. You might be okay with brief, intermittent exposure, but a lot of materials require at least a full minute, if not much longer, to sublimate properly, so VOC safety becomes a real concern.

I’ve provided a handy table of my experiments and results. After the table are comparison photos of each project – pressed with the hand press, and then a second copy pressed with my HPN press (mostly). Click each photo for a larger view.

Except where noted, these projects were pressed with no human leverage applied, relying only on the weight of the H10, which on its own applies nine pounds of pressure. It’s also important to note: more pressure is required for larger surface area. You aren’t going to successfully sublimate anything covering a full 12×10″ without some additional leverage. The largest item I used in my tests was a slate coaster just under 4″ diameter.

| Substrate | °F | Time | Result |

|---|---|---|---|

| Acrylic | 320° | 80s | ➖ |

| PET | 340° | 60s | ✅ |

| Aluminum | 355° | 90s | ✅ |

| MDF | 355° | 35s | ✅ |

| Nylon | 355° | 50s | ✅ |

| Slate | 355° | 500s | ➖ |

| Glass | 390° | 180s | ✅ |

| Ceramic | 400° | 200s | ⛔ |

| Neoprene | 400° | 45s | ➖ |

Acrylic (60x40mm keychain)

Without any additional human leverage, this acrylic keychain turned out pretty well, aside from the obvious fading around the edges of the image. This effect may not be a problem for crafters, but it’s not great for items you’re producing for resale. I was pretty happy with my results, especially compared to my EasyPress, which was so inferior, I stopped trying. Note that with adequate leverage, the H10 can successfully sublimate acrylic edge-to-edge.

PET (business card)

PET is a very forgiving sublimation substrate, because it is essentially a sheet of polyester, and polyester polymers are sublimation dye’s best friend. My PET sample card turned out really nicely with the weight of the H10.

Aluminum (40x60mm keychain)

Aluminum sublimated nicely with the H10, but without additional pressure, I noticed more visible ink blowout. This is primarily a problem for resale. For crafters, it’s usually a negligible difference.

MDF (2″ keychain)

I am really happy with how well MDF sublimated, and I’m even happier with how the H10 improved the overall workflow with MDF. This particular substrate is a bit of a beast to use, because the glues used smell absolutely atrocious when heated during sublimation. I really dislike pressing MDF for this reason. Beyond this, the pressure of a lever or swing heat press often results in tape leaving a slight impression on the surface of the MDF, as the material’s surface softens slightly during pressing. The H10’s weight was enough to sublimate my keychain blanks cleanly without tape marks, and the portability of the H10 means I can use it in an area with better ventilation, rather than my basement maker space.

Nylon (40x80mm keychain)

The nylon used for sublimation products is a tight, smooth weave and makes for an excellent sublimation substrate. I was very happy with the H10’s results. I do my double-sided sublimation by making the print into a little pouch, so I don’t have to tape on the sublimated side. I had no problems using this method with the H10.

Slate (approx. 4″ coaster)

Slate sublimated reasonably well, but without additional leverage, the H10’s nine pounds of pressure made for a slightly blurred image. It’s not bad enough to be unusable for both gifts and own personal use, but it’s probably not quite good enough for resale.

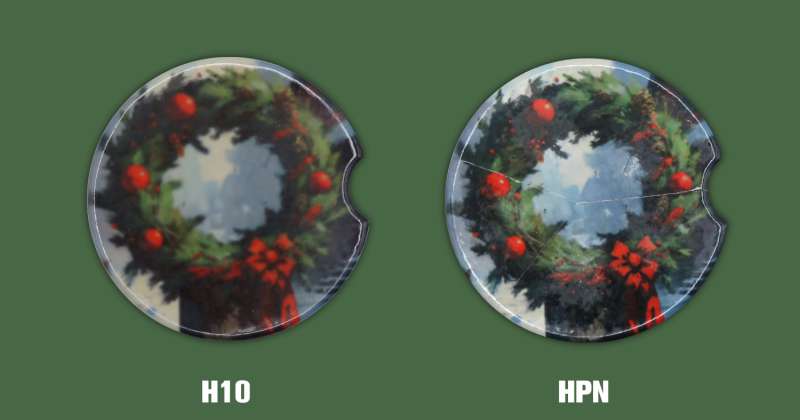

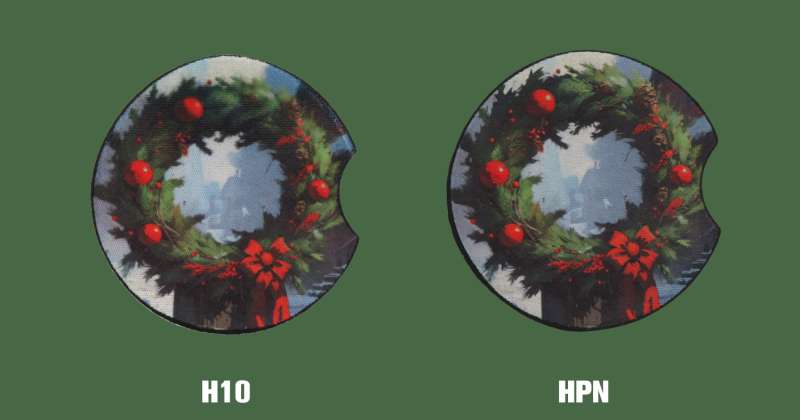

Ceramic (approx. 65mm car coaster)

Confession: I really hate pressing ceramic. I’ve only gotten consistently good results with vacuum sublimation, which is considerably more expensive than standard sublimation with regular paper and a press. The H10 doesn’t apply enough weight on its own to properly sublimate ceramic, and the long press time (200 seconds – over three minutes!) means leaning over the press to apply leverage is infeasible due to the safety profile of the sublimation ink. I will continue avoiding pressing ceramic, unfortunately – as you can see in my photo, my heat press cracked the ceramic! Dialing in the pressure is really tedious and difficult with flat ceramic, especially when working with inexpensive imported blanks.

Neoprene (approx. 65mm car coaster)

Rubber-backed neoprene smells terrible when pressed, so this is another material where you won’t want to be hanging over the press to apply leverage. The downside is, the flexibility of neoprene means the edges will blur pretty easily if you don’t use enough pressure. This results in items which are good enough for gifts and personal use, but they are unsuitable for resale.

What I like about the HTVRONT H10 Heat Press

- Dual-handle design is better for the 12×10″ size

- Realtime pressure feedback ensures consistent results

- Preheats quickly – just under four minutes to 320° F

What can improve?

- Include a silicone mat!

Final Thoughts

The HTVRONT H10 Heat Press is a full-featured handheld heat press for general craft, hobby, and sewing use. It’s also reasonably suitable for hobbyists looking to get into sublimation without breaking the bank, since a quality full-size heat press is a bigger investment. It won’t work well for sublimating ceramic coasters and tiles, but it performed well enough with everything else I tested to work for making gifts for your loved ones and colleagues. Its portability and rapid preheating will make it my first choice for sublimating keychains, business cards, and other small items, and I will definitely be using it for future vinyl textile projects.

Regular Price: $129.99

Deal Price: $89.99

You Save: $40.00

Where to buy: Amazon

Source: The sample of this product was provided for free by HTVRONT. HTVRONT did not have a final say on the review and did not preview the review before it was published.

The novel features of this heat press set it apart from the competition and make this an excellent buy for crafters and makers alike!

![[Strong Magnetic Lock]:Built-in magnets, offering a magnetic force of up to 3000g. Ensures the magnetic wallet fits tightly and attaches securely to the back of your iPhone. [Smart Card Storage]:The magnetic wallet is designed ingeniously to hold 5 c...](https://m.media-amazon.com/images/I/41SFnxrNs0L._SL160_.jpg)