REVIEW – I’ve been a woodworker for most of my life. Starting with simple tools and crude techniques, I think I’ve improved over the years. Advances in woodworking have truly been extraordinary. It’s a great time to be a woodworker. CNC machines are what I consider the pinnacle of these advances. Projects that can be accomplished today can be done in a fraction of the time it took in the past. The TwoTrees TTC6050 CNC Router Machine is one such incredible advancement. Let me tell you about it and the fun I’ve had using this machine over the last two months.

⬇︎ Jump to summary (pros/cons)

Price: $1,499.00 (CNC machine), $139.00 (800W motor), $99.00 (Vacuum), $54.00 (bits)

Where to buy: www.twotrees3d.com, Amazon

What is it?

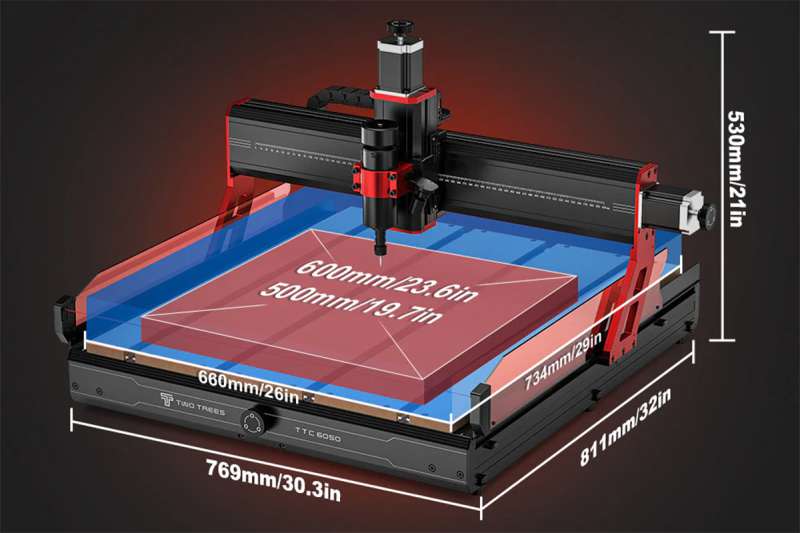

The TwoTrees TTC6050 CNC Router Machine is the latest (and largest) CNC machine from TwoTrees. It comes standard with a 500W spindle that boasts a 12,000 RPM maximum speed. Its working area is a generous 23.6in (600mm) deep x 19.7in (500mm) wide x 4in (100mm) high. It can carve wood, plastics, and soft metals. It comes with an advanced and highly featured controller that has a touchscreen and WiFi connectivity.

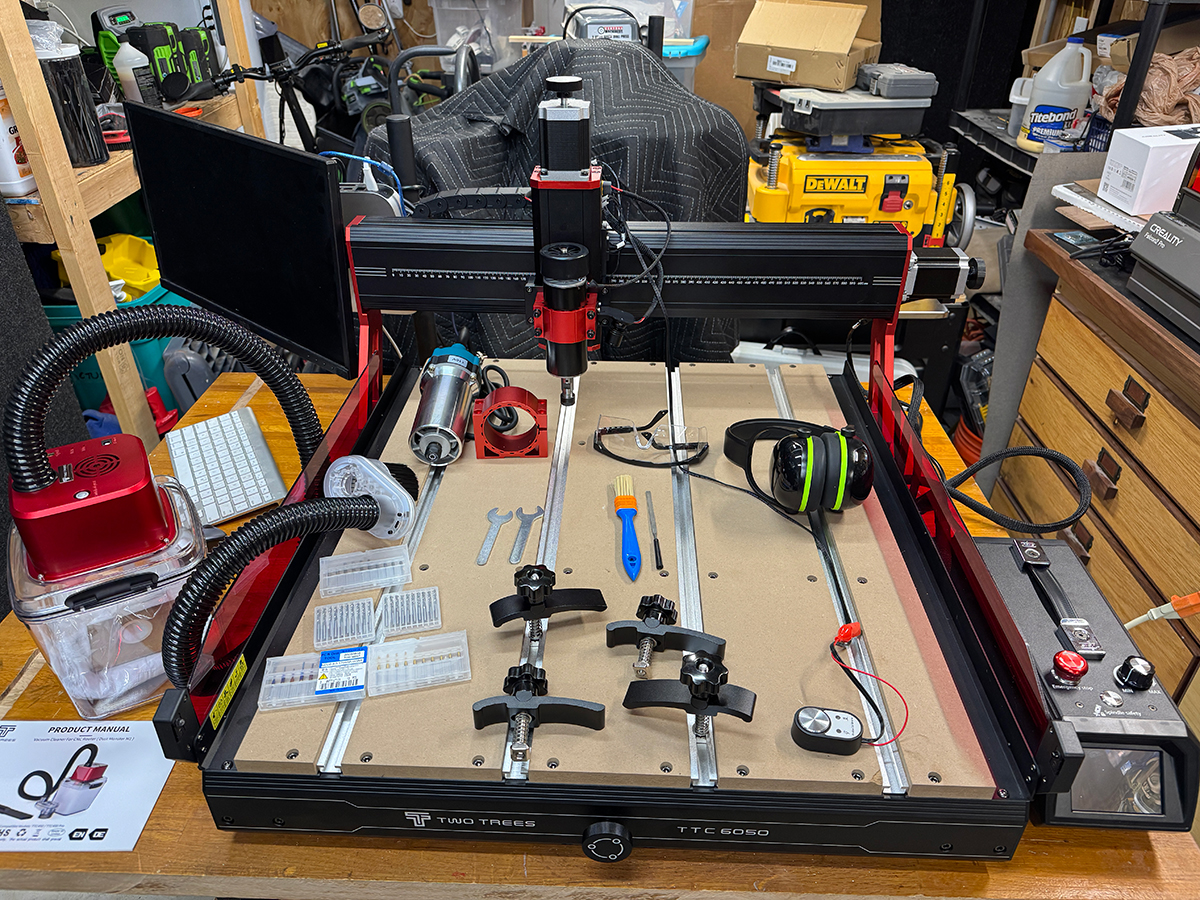

What’s included?

- TTC6050 CNC Machine (95% unassembled)

- 500W Spindle

- Controller with Touchscreen

- 4 Material clamps

- Power Supply

- Tools

- Bit Height Probe

- Safety Glasses, Hearing Protection

- Instruction Manual

- Extras provided for this review: 30,000RPM Wood Router for CNC Machine, 40 PCS End Mills CNC Router Bits, CNC Vacuum Cleaner Monster (M1) Kit

Tech specs

TTC-6050 CNC Machine

- Frame Material: Aluminum

- Engraving Area: 23.6in (600mm) x 19.7in (500mm) x 4in (100mm)

- Max Speed: 5000mm/min

- Engraving Accuracy: 100±0.05mm

- Spindle motor: 500W

- Spindle Speed: 12,000 RPM

- Collet: ER11

- Waste board: MDF, Replaceable

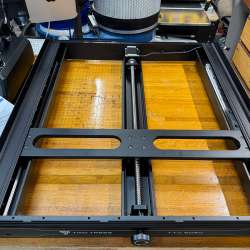

- Transmission Screw Models: Ball Screws + Linear Guides

- Controller display: 3.5-inch IPS resistive color screen, touch (480 x 320 pixel resolution)

- Lighting: 500lm spotlight

- Safety features: Emergency Stop & Infrared Sensor

- Compatible software: VCarve, Fusion360, EASEL, Carveco Maker

- Materials: Wood, Plastic, Soft metals like aluminum, and PCB materials

- Weight: 79.15lbs (35.9kg)

- Overall Dimensions (LxWxH): 31.93in (811mm) x 30.28in (769mm) x 20.87in (530mm)

- Warranty: 1 year

800W Router for Heavy Duty Carving

- Rotation Speed: 10,000 – 30,000 RPM

- Collet: ER11

- Weight: 2.87lbs (1.3kg)

Vacuum

- Motor: Brushless

- Motor Speed: 50,000 RPM

- Startup Modes: Manual and Automatic

- Dust bag: Cloth, 2.8L capacity

- Hose diameter: 1.38in (35mm)

- Hose length: 50in (1260mm)

- Crevice nozzle included

- Dimensions (LxWxH): 6.69in (170mm) x 6.69in (170mm) x 9.45in (240mm)

Introduction

Before jumping into the (spoilers) awesome time I had with the TwoTrees TTC6050 CNC Router Machine, I need to say I stand on the shoulders of those who came before me. Although I’ve never owned or operated a CNC machine before, I knew quite a bit about them from research, and being enrolled in the University of YouTube. I have probably watched hundreds of videos about CNC machines and what you need to know before buying one. Things like speeds, feed rate, plunge rate, end mills, v-bits, uncut, downcut, etc. I thought I knew most of this, but putting it into practice was what I was missing.

My fellow Gadgeteer, Kathleen Chapman, reviewed the previous TwoTrees CNC machine, the TTC450. Her review is a master class on all things CNC. She not only reviewed the TTC450 but also documented her entire journey of discovery in the world of CNC. If you are new to the CNC universe, please read her review first, and then come back here to see how I put what she taught me into practice with the TTC6050. Thank you, Kathleen!

Design and features

The TTC6050 comes in two large, heavy, somewhat adequately cushioned boxes (see below). The instructions give you guidance on how to unpack everything to get prepared for assembly. See the next section for details on the assembly experience.

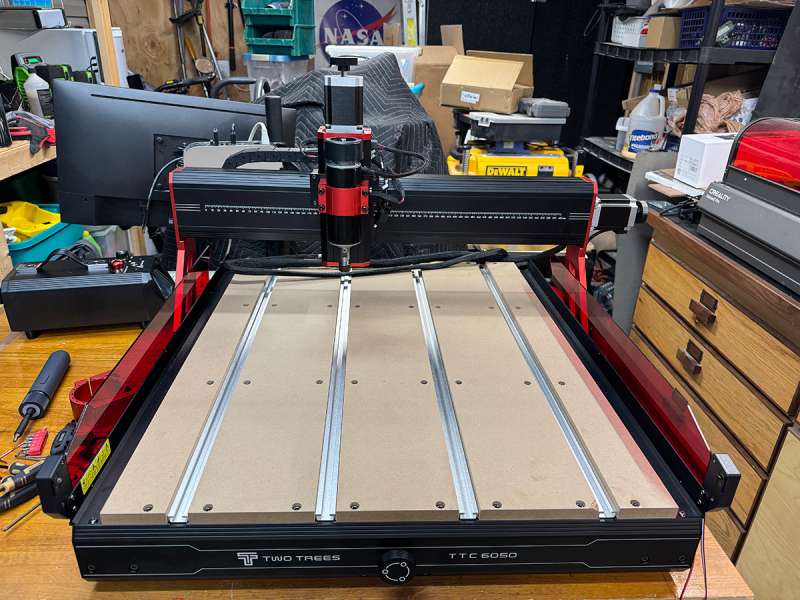

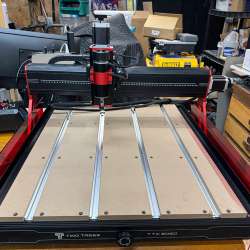

The TTC6050’s frame is all extruded aluminum, with some trim pieces that are plastic or plexiglas. The entire machine weighs in at 79 lbs (35.9 kg). So it’s not going anywhere once it is assembled and in its place. The drive mechanisms of the TTC6050 are precision-machined ball screws and very hearty stepper motors.

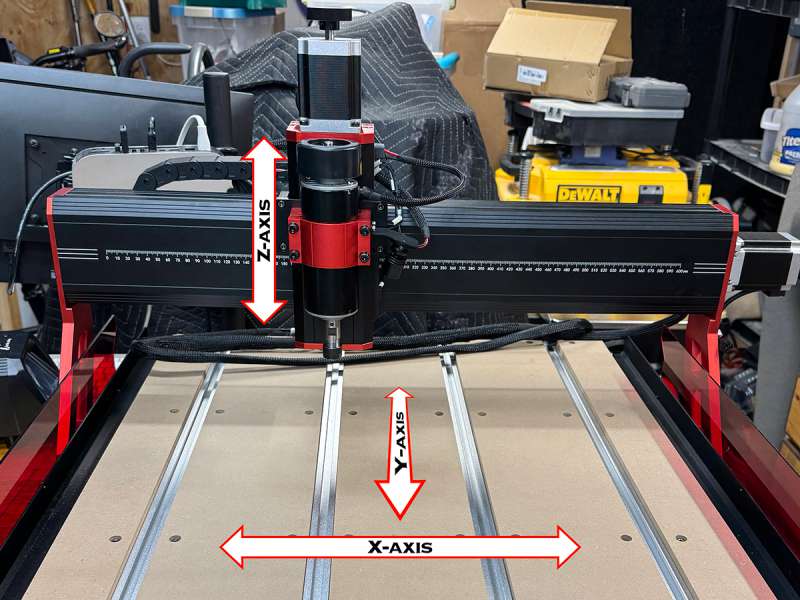

The job of a CNC is to translate a 3D design into movements of the spindle (or router) with the attached carving bit to precise locations in 3D space, along the X, Y, and Z axes. The stepper motors and ball-screws work in tandem to move the router to where it needs to go to complete the carving project. It’s a wonderful dance of high-tech and mundane woodworking. All of this control is accomplished via the chosen software and the controller of the CNC machine.

The brain of the TTC6050 is the Controller, which is an external, separate box that sits to the right side of the frame/working area. It has a nice, clear, 4.3in touchscreen display. It has USB and Wifi connectivity, as well as, an SD-card slot for complete offline operation. I have a computer in my shop that I used to control the TTC6050 via the USB port, so I did not use the SD-card or WiFi features very much.

One main feature of CNC machines is in the working area. This is the depth, width, and height that the machine can work within. These measurements are expressed as Width x Depth x Height. Some CNC machines are as small as 8 × 8 × 2 in (203 × 203 × 51 mm), to as large as 60 × 120 × 8 in (1524 × 3048 × 203 mm). The TTC6050 comes in toward the medium-sized hobbyist market of 23.6 x 19.7 x 4 in (600 x 500 x 100mm). This size is great for a home workbench.

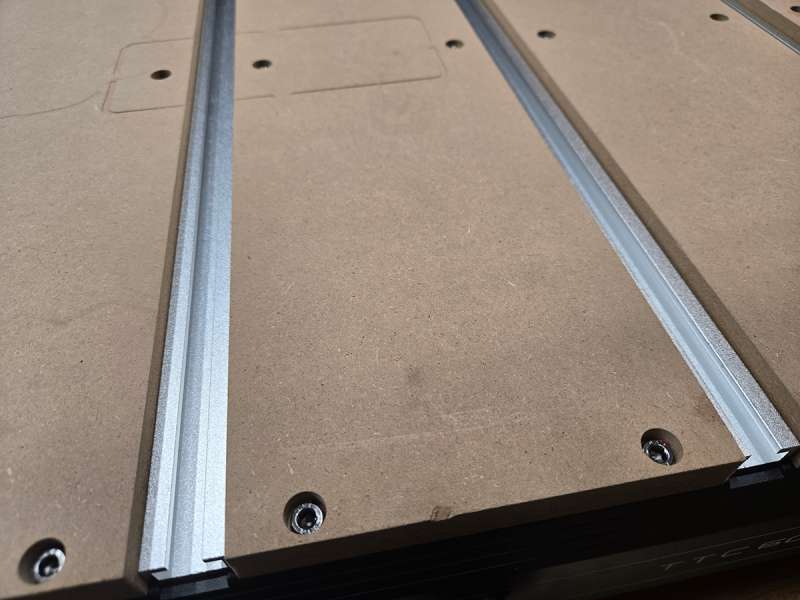

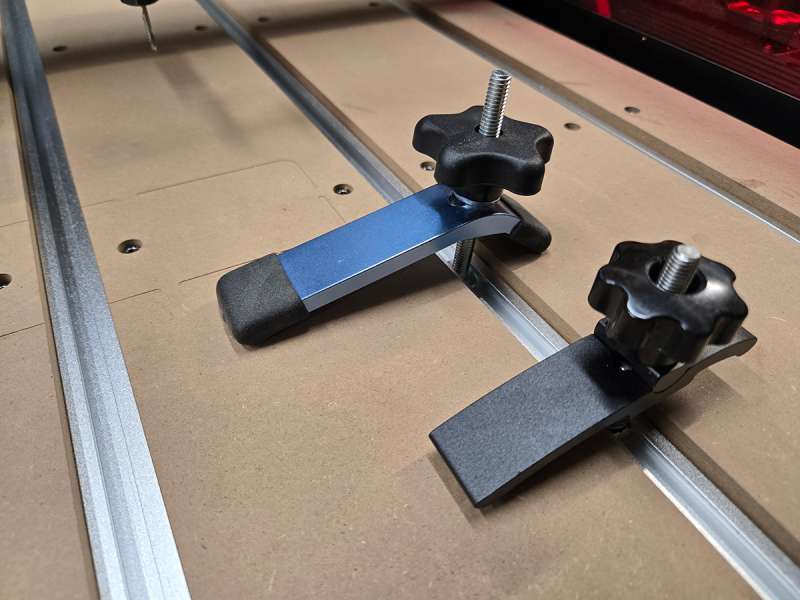

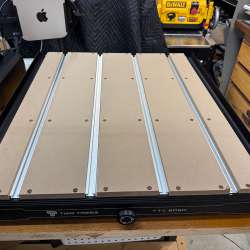

The working area of the TTC6050 consists of two main components: a replaceable, sacrificial MDF waste board and aluminum T-tracks for holding down the material being carved. The waste board is slightly raised to avoid carving into the aluminum T-tracks when the project’s design calls for cutting all the way through the material. The TTC6050 comes with 4 hold-down clamps that slide in the T-tracks for holding the material secure during engraving. Along the sides of the working area are plexiglass walls and channels to help contain any wood chips that are produced.

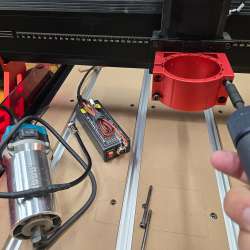

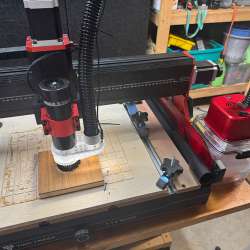

The TTC6050 comes standard with a 500W, 12,000 RPM spindle/motor. The spindle holds the bits that do the carving. The spindle supplied with the TTC6050 (on the right) can hold 1/8 in (3.18 mm) bits. That is to say, the shank of the bit, the non-cutting part of the bit, is 1/8 inch in diameter. For larger bits, say 1/4” bits, which are needed for many situations, a larger motor is needed. TwoTrees does sell a larger, 800W motor (on the left, above) that can reach speeds of 30,000 RPM. TwoTrees did supply this larger motor for the sake of this review.

The spindle/motor is held by the Z-axis component. This Z-axis component moves the spindle/motor up and down to produce the depth or height of the project’s design. The X-axis (or left/right) movement of the motor is accomplished by the large gantry that is holding the Z-axis component. The Y-axis (or forward/back) movement is accomplished by moving the X-axis gantry forward and backward. The large red brackets on the left and right sides of the TTC6050 give the machine a very stable, solid movement in the three dimensions.

Each of the axes has a knob so that the spindle/motor can be precisely positioned manually before carving begins.

The TTC6050 comes with a bit height probe. Used when setting up a carving, the probe tells the software exactly where the top of the material is in relation to the bottom of the bit. The CNC lowers the bit until it touches the probe, and then raises the bit above the material. It is now ready to begin carving.

The TTC6050 and its controller have two safety features. The first safety feature is a large red emergency stop button on the top of the controller. Hitting the emergency stop will cut power to the machine immediately. Also, there are infrared sensors on the leading edge of the working area. These sensors monitor the work area for intrusions by hands or tools. When the infrared beam is broken, the spindle rotation and the X/Y/Z movement of the machine are halted in less than one second. The controller screen will have a warning and an option to resume engraving.

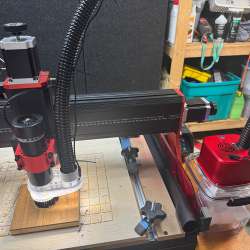

Running a CNC produces a lot of wood chips. Not really sawdust in the traditional sense, but slightly larger wood chips. As you can imagine, this can cause quite a mess. Chip collection is another aspect to consider with any CNC. Most CNCs to not come with their own chip collector, or vacuum. The TTC6050 also does not come with one standard, but TwoTrees sells a vacuum for use with their TTC450 and TTC6050 CNC machines. TwoTrees did supply the vacuum for the sake of this review.

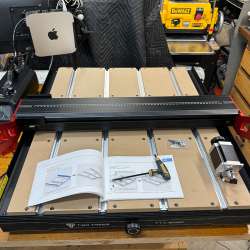

Assembly

The TwoTrees TTC6050 CNC Router Machine arrived in two very heavy, large cardboard boxes. Inside these boxes are all the pieces and parts needed to assemble the machine. In Kathleen’s review, she says the TTC450 came about 95% assembled. The TTC6050 came the exact opposite. It was about 95% unassembled. All in all, it took me about 4 hours to assemble the TTC6050.

Assembling the machine’s frame and working area was pretty straightforward. There are many, many parts, but the steps are laid out well in the instructions. I didn’t run into any issues assembling the main components.

One issue was the included Allen wrenches. As with any product that requires Allen wrenches, I immediately toss them into my junk tool drawer and grab my mechanic’s Allen wrench set or my HOTO tools set, reviewed here. Makes assembly so much easier on my hands.

Once all the hardware components are assembled, the wiring of the motors, limit switches, and infrared sensors is next. The TTC6050 comes with a fairly beefy wiring harness. All of the connections are spaced and measured to fit perfectly where they need to go. Unfortunately, the instructions are severely lacking in explaining where all the wiring connects on the machine. I scoured the internet for information on how to get this step done, but with the TTC6050 being so new at the time, there were no resources, even on the TwoTrees website. At long last, I found a YouTube video from someone who had received their TTC6050 just a week or so before I did. They also had a hard time completing the wiring, yet they figured it out and then posted a video of wiring the TTC6050. It was a godsend. After about 30 minutes, I had it all wired up, and it was ready to go.

TwoTrees also provided the more powerful 800w spindle/motor. Installing that was fun little excursion in frustration. The included instructions with this motor were for installing it onto the TTC450, not the TTC6050. I reached out to TwoTrees, and they gave me a few clues as to how to do it. They did not have any instructions or videos ready yet for the TTC6050. I eventually got it connected and working. See below in the Performance section for how this motor performs.

TwoTrees also provided their vacuum, called the Monster M1, to try out. Why it’s called the Monster M1, I have no idea. The assembly of the vacuum accessory was the smoothest of all the assemblies required. The instructions were straightforward and got me to the finish line perfectly. See how it performed in the next section.

Here’s a montage of the assembly process, sped up, of course. Who wants to watch a 3-hour video of me screwing in screws and yelling at the wiring harness?

Performance

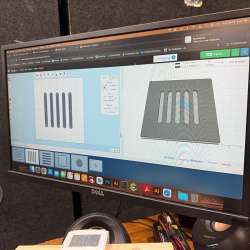

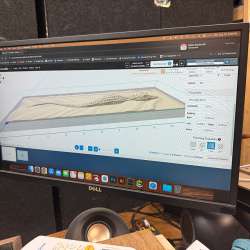

I was so excited to try out the TwoTrees TTC6050 CNC Router Machine. I had it all assembled, wired up, and was ready to go. With several laser etching machines I have reviewed for The Gadgeteer, I always test their accuracy by drawing a circle in the controlling software and let the machine do its thing. I then measure the circle and see if it reproduces the circle accurately. I chose to use Easel Pro software, as it seemed the easiest to learn, and the concepts seem to translate easily to LightBurn, which I used for my laser etching.

In Easel Pro, I drew a simple circle in the design space. Selected a simple 1/8” straight bit, set a moderate speed for movement, and hit the Carve button. Oh my. The TTC6050 produced a horrible sound of metal-on-metal grinding inside the X-axis gantry. The carved circle looked more like an egg. Uh oh. Unfortunately, I did not take a picture of this.

I reached out to TwoTrees, and as I waited for their response, I became impatient. I decided to investigate the issue myself. After a little disassembly of the X-axis gantry, I found that a bracket had come off because two screws had come out during shipping. I think one of the boxes was dropped, and caused the threaded holes for these screws to be stripped out. The main ball-screw, which moves the spindle/motor left and right, had become detached. I took a bunch of pictures and reached out again to TwoTrees support. After a little back-and-forth, they decided they would have to send out a new piece for the X-axis gantry. Unfortunately, they didn’t have any spares and would have to manufacture the piece and send it from China. [Queue the Jeopardy theme] Almost 3 months later, I received the replacement part. I had to transfer all the internal components from the broken gantry to the new one. Once that was done, I reran the circle test, and it worked perfectly. Kudos to the TwoTrees support. Although it took a long time to remedy, they kept me up-to-date with the status of the replacement during that time.

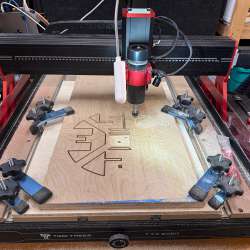

With the machine all fixed and with the circle test passed, I loaded up the two test files that TwoTrees supplies. A relief carving of a small flower, and some simple lettering of “TTC6050”. Both of these files carved well into the piece of scrap pine I had lying around. Pine doesn’t carve well and leaves the finished project all fuzzy. Off to the woodworking store for some better lumber to work with.

My first real project was a new surface for the working area. I didn’t want to carve up the MDF that was used as the sacrificial surface. I got that suggestion from a CNC video I had watched. So I drew a simple 1-inch grid pattern, clamped down a piece of 1/2” plywood, and let the TTC6050 carve it up. I’m so glad I did that, as the grid pattern lets me line up material for my projects very easily.

My next project was something I’ve always wanted to make, a Jack-O-Lantern lantern. The TTC6050 carved away the facial features with ease. I then completed the lantern by adding sides and a top and bottom. Added a couple of RGB LED lights, and viola! A Jack-O-Lantern lantern.

(Click on any picture to see it full-sized)

I then tried a slew of other materials for various projects. Hard maple, multi-layer/color plastics, a bamboo multi-layer material called BamX, plywood, wood coasters, etc. Did all my projects come out well? No. Did I learn from each time I screwed up the carving settings? Yes. Go back to Kathleen’s review of the TTC450. Her documenting the process of learning what all the CNC settings mean and why they are important is invaluable.

The controller for the TTC6050 is very full-featured. It has many screens and options at would make using the machine offline very easy. I only ran the two test files via the included SD card right from the controller. All other projects, I did through the Easel Pro software. About the only time I interacted with the controller was when I had inadvertently tripped the infrared safety sensors during a carve. A quick little tap on the screen, and the carving would continue. One issue I found was that it would not save the WiFi password. After powering off the controller, it would not reconnect to my Wifi network and would require me to enter the password again. I quickly gave up on trying to access the machine wirelessly.

The included hold-down clamps were very small. I ended up replacing them with longer T-track clamps I found on Amazon. They were cheap and a great replacement.

The difference between the two spindles/motors wasn’t as obvious as I thought it would be. Even though the bigger 800W spindle/motor could hold 1/4” bits, and perform carvings in less time than the smaller 500W spindle/motor, the results were about the same. Also, 1/4” bits are much more expensive than the smaller 1/8” bits the 500W spindle uses. I tended to use the smaller 500W spindle more often because I was able to purchase more 1/8” bits for less money for this review.

Speaking of bits. TwoTrees sells and sent me a set of 40 1/8” bits. This set included many different kinds of bits for different project types. Once again, refer to Kathleen’s review for bit types. These bits tended to break more easily than bits I had purchased separately. I broke many bits as I was learning what bits to use in different situations. That is just part of the CNC world.

The vacuum accessory was such a valuable add-on. Making a mess is just part of woodworking, especially with a CNC. I highly recommend purchasing a vacuum with a CNC. The vacuum attaches to the 500W spindle/motor very easily. It has a nice integrated light that illuminates the workpiece very well. It cleans up about 99% of the chips during a carve, making cleanup after the carve significantly easier. The Monster M1 vacuum comes on when a carve starts, and shuts off when it finishes. It’s well worth the money.

Here is a video of the TTC6050 running through a few of the projects shown above.

Final thoughts

The TwoTrees TTC6050 CNC Router Machine is a reliable and robust hobbyist CNC. It would fit in most woodworking shops and be a valuable tool in a short time. The frame and components are very well-made and work great together. For the weekend woodworker, it would be a solid investment. If you are looking to batch out large quantities of things to sell, I don’t think the TTC6050 is the best machine. If you’re looking to get into the CNC world and maybe make a little money on the side, you wouldn’t do wrong with the TTC6050. I highly recommend it.

What I like about the TwoTrees TTC6050 CNC Router Machine

- Excellent customer service

- Very sturdy, robust machine

- Highly accurate

- Can work with a wide variety of materials

What needs to be improved?

- Padding around larger components in the packaging

- Assembly Instructions are lacking

- Material hold-down clamps are small

- WiFi password was not saved in the controller

- 40-piece set of bits break easily

Price: $1,499.00 (CNC machine), $139.00 (800W motor), $99.00 (Vacuum), $54.00 (bits)

Where to buy: TwoTrees, Amazon

Source: The sample of this product was provided for free by TwoTrees. TwoTrees did not have a final say on the review and did not preview the review before it was published.

Check out these other CNC machine reviews!

- LUNYEE 3018 Pro Ultra CNC Machine review – a great entry to the world of CNC

- TwoTrees TTC-450 Pro CNC Router Machine review – Everything you need to know!

Gadgeteer Comment Policy - Please read before commenting

Hey Patrick! Thanks for the really nice shout-out!

When I read that you had an issue with stripped screws that held a bracket in your X-axis gantry, I thought to myself, “Oh noooo…”, but I must say, it wasn’t entirely a surprise. I’ve had a handful of parts that needed replacing on TwoTrees devices. Thankfully, tech support is helpful. But I’ve never had to wait 3 months to get the part replaced!

I really loved your projects – you had some fantastic results! The alligator, clock, and Federation of Planets coasters were some of my favorites. I think you’ve surpassed my level, especially with two-sided carving (the wooden trivet). I don’t know how you did that. I’m not a woodworker, so I’m sure it takes some precise placement.

Did any of your projects need a lot of post-processing (sanding, etc)?

Fantastic review!

I was thinking about the trouble you and I had with our CNCs. Their service is great and responsive, but I hope they learn from the issues and correct any manufacturing/packaging/instruction writing to help future buyers.

The trick for two-sided carving is to make sure to get the piece in the exact same place on the spoil board for both sides. I used screws for one project, and markings and double-sided tape on the spoil board for the trivet.

The clock needed a lot of sanding because it was plywood. I should have used a hardwood, but I didn’t want to have to glue up a panel. The clock is 13″ wide. The alligator also needed a lot of sanding because I used the wrong bit for the detail pass. I should have used a slightly larger bit. The inverse Gadgeteer logo came out perfect. No sanding needed at all. So, I think a combination of the right wood and the correct bit can minimize the sanding needed.

Thanks!

It would be wonderful if TwoTrees learned from the issues we’ve had and produced better video setup instructions and written instructions for users. However, I haven’t seen any indication of that based on your issues with the lack of wiring instructions (I had wiring issues with my CNC and the 500W spindle and setup issues with the rotary accessory). *Sigh*

Thanks for the tips on how to do the double-sided carving. I may give it a try.

Finding that sweet spot (the right wood, correct bit, and settings) to produce the perfect project with minimal post-processing is what I want without all the trial and error (lol)!

One more question – did you create the carving files for the projects yourself or did you find the files elsewhere?

Both. The Star Trek coasters, clock, trivet, and the red/white sign were created by me in Photoshop/Illustrator and imported into Easel. The rest I found online or in the Easel shared projects. The inverse Gadgeteer logo took a little work in Easel to get the carving areas figured out. The alligator I bought off Etsy for a couple of dollars.

Great review. I am just getting into woodworking and have made a few cutting boards, an outside planter, and a cabinet I use to hold my 3D printer. I have been thinking about using epoxy for infills like you did on the Star Trek coasters (Live long and prosper!!!). What epoxy did you use for the small infills like that? I know you don’t need deep pour epoxy. Thanks for your help!

I just bought a cheap epoxy kit from Hobby Lobby. I think it was around $25. Make sure to mix it correctly. One of the coaster’s infill took forever to cure because I didn’t mix it perfectly.