REVIEW – A few short years ago, I’d never seen a 3D printer in the wild. In 2021 I got my hands on my first 3D printer to review: the ANYCUBIC Vyper 3D printer. Since that first printer I’ve lost count of how many printers I’ve reviewed and bought, but I currently have a print farm with ten different machines running 24/7 (the hobby has turned into a part time job selling on Etsy and Amazon). For my print farm, I have to balance price with reliability and quality. I have 4 different Bambu Labs models running including A1s, P1Ss, and H2Ds. The CoreXY machines (P1S/H2D) have been much more reliable for my larger models than the “bedslingers” (where the whole bed moves front to back like the A1 series). When the model you’re printing is larger and heavier, the belts and motors can struggle to move the increasing mass quickly, but on a CoreXY machine the model isn’t being moved around as much (instead, the print head itself is doing most of the movement). The Anycubic Kobra S1 is very interesting to me because it offers the advantages of similar machines already in my farm with some new tricks (like drying filament while printing). Will it meet my quality and reliability needs? Read on!

⬇︎ Jump to summary (pros/cons)

Price: $749 (on sale for $549 at time of review)

Where to buy: Anycubic

What is it?

The Anycubic Kobra S1 3D Printer is a FDM (fused deposition modeling) printer. It uses an enclosed CoreXY structure (good for high speeds and stability) and supports multiple color filament printing through the ACE Pro filament dryer and feeder. Even if you’re not doing multiple color models, it can be very nice to have something like the ACE Pro where you can load 2+ rolls of the same filament and instruct the printer to automatically start using the next roll when the first runs out, ensuring no pauses in printing. The printer supports pretty much any popular filament (including high temperature filaments like ABS/ASA).

What’s included?

- Anycubic Kobra S1 3D Printer

- ACE Pro

- Spool holder

- Signal cable x1

- Filament tube x4

- Power cord x2

- Screws and tools

- USB disk (with software and pre-sliced test models)

- Filament sample

- Nozzle cleaner

- Activated carbon packet

- Nozzle cleaning module

- Nozzle silicone part

- Cable/PTFE tube organizer (x2)

Tech specs

Print volume: 250 x 250 x 250 mm

Kobra S1 Dimensions: 400*410*490mm

ACE Pro dimensions: 365.94*282.84*234.5mm

Printing speed: 300 mm/s recommended, 600 mm/s maximum

Noise: Standard mode: as low as 46dB; Quiet mode: as low as 44dB

Machine weight: Kobra S1 18kg, ACE Pro 4.6kg

Recommended materials: PLA, PETG, TPU (externally fed, not in ACE Pro), ABS, ASA

Nozzle temperature: up to 320°C

Hotbed temperature: up to 120℃

Nozzle diameter: 0.4mm standard, supports 0.2-0.8 mm in slicer

Pressure advance: Supported

Flow calibration: Supported

Printer structure: CoreXY

Extrusion: Dual gear direct drive

Hot end: metal, quick-detachable

Air filtration: Activated carbon purification

Control screen: 4.3″ capacitive touch screen

Resume from Power-off: Yes

Filament detection: Yes

Camera: Yes

Remote monitoring: Yes

Time-lapse: Yes

Door and top cover material: Polycarbonate

AI detection: Spaghetti recognition

Skip objects while printing: supported

Multicolor support: Up to 8 colors (with 2x ACE Pro)

Design and features

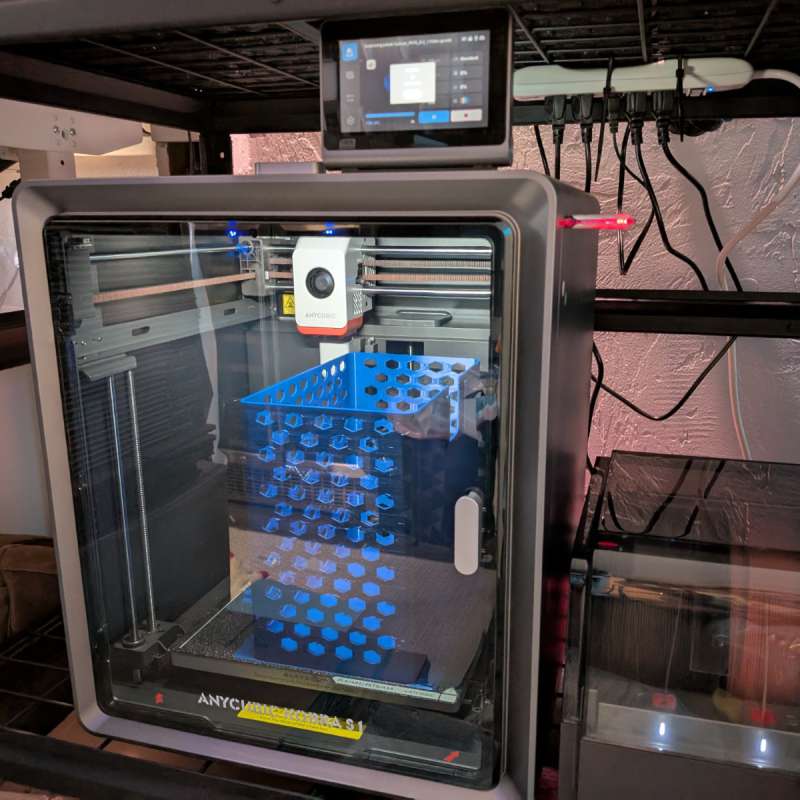

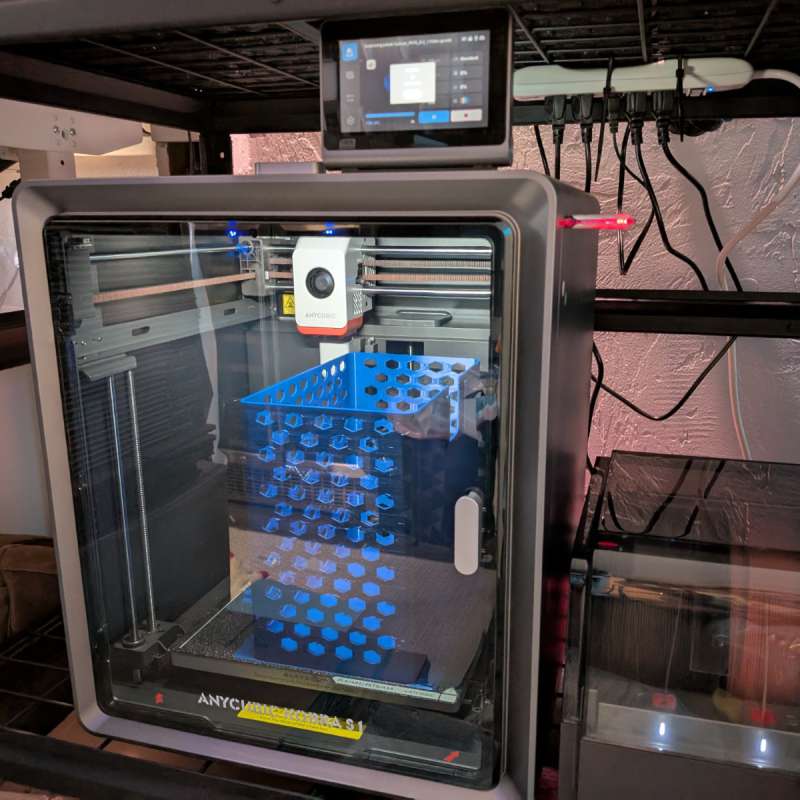

The basic design of the Anycubic Kobra S1 3D Printer combo is very similar to the most popular CoreXY printers on the market: basically it’s a large cube shaped unit with a screen. The ACE Pro filament dryer/feeder can either be placed on top of the printer or to the side. A large clear door gives you great visibility from the front and a similar clear panel on top allows for even more visibility and access. Anycubic has a nice internal LED lighting kit in this model that allows you to check up on your prints (in person or through the camera remotely).

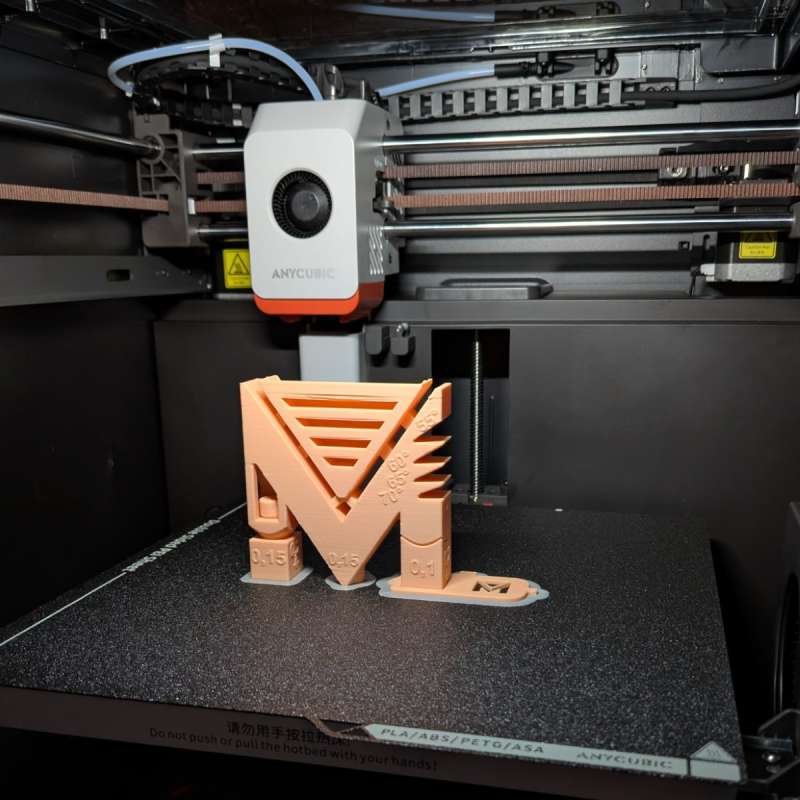

The print head is a large rectangular block of plastic, which hides an internal dual-gear extruder and a clever quick-release nozzle mechanism. The front cover pops off fairly easily for maintenance or nozzle changes, and swapping a nozzle is as easy as unplugging one wire connector and then flipping a lever to pop the old one out. You can then push the new one in and close the lever, then reattach that wire connector and you’re done. I didn’t have any clogged nozzles during my testing but I like that it’s a quick-change style since the more common screw-on nozzle always takes a lot of force to get off and I worry about breaking things whenever I change one like that.

The above shot shows the touchscreen as well as the top panel. Said panel can easily be lifted off to provide easy access from above (either for ventilation or maintenance access).

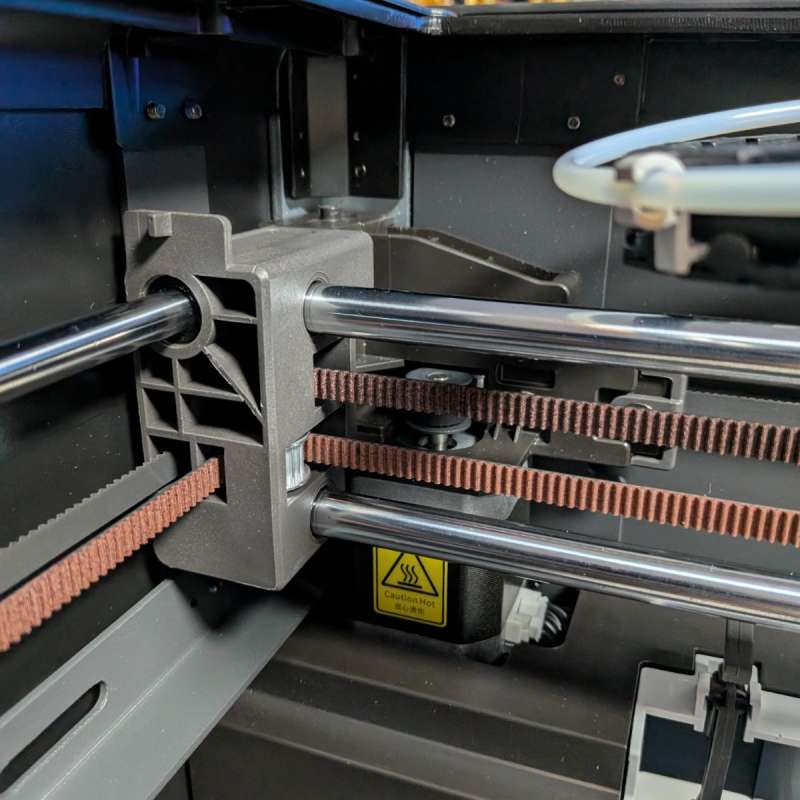

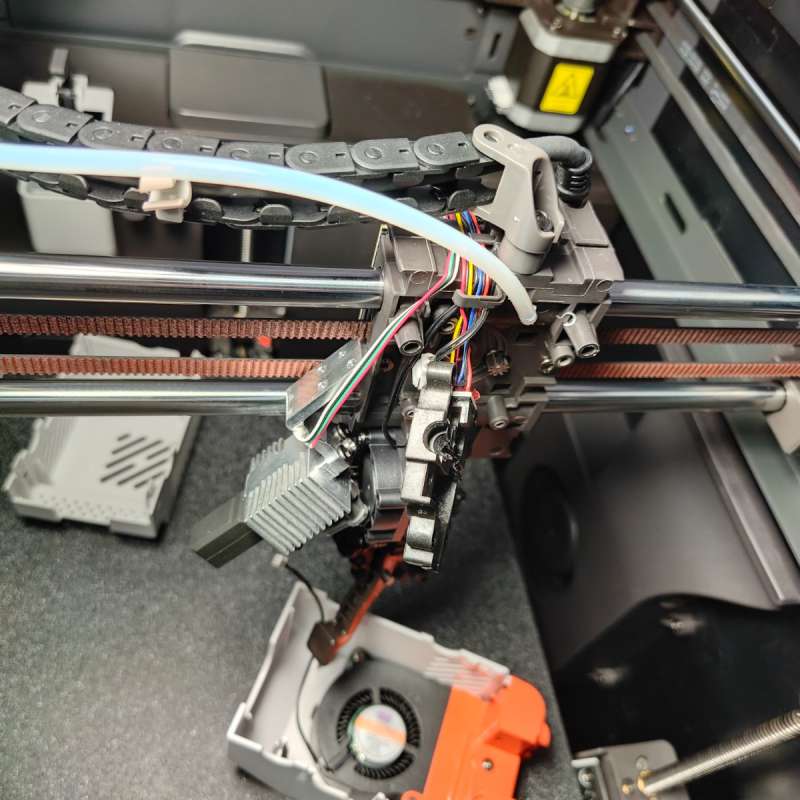

A CoreXY printer uses clever long belts that allow a few motors to quickly move the print head in the X and Y directions simultaneously. The metal rods you can see in the picture above act as rails for the print head to slide along while the belts and motors are doing the work.

Meanwhile, the print bed is moved up and down via lead screws (the threaded rods in the image above).

The ACE Pro filament feeder/dryer can hold up to 4 different spools of filament (pretty much anything but TPU – that can’t be run through the ACE Pro but can be used if fed externally). The ACE Pro has RFID readers inside that can detect and change settings for specific filaments. This worked perfectly for the 4 assorted rolls that Anycubic provided for my review. For other spools without RFID chips (or other brands) I simply had to define each filament slot type and color through the control screen, which was easy enough.

In the back of the printer there is a waste chute and nozzle wiper. The machine will “purge” blobs of plastic between color changes and between prints, then drop these out the back of the machine. The nozzle is then wiped on the Teflon-coated nozzle wiper to clear off any remainders and start printing the next color.

A provided USB drive plugs in the right side of the machine and acts as the storage system for files you send to the printer as well as timelapse videos (which you can toggle on for any print). There’s a selection of ready-to-print files and software on the USB disk so you can install on your computer without the need to download (though you should probably grab the latest off Anycubic’s website).

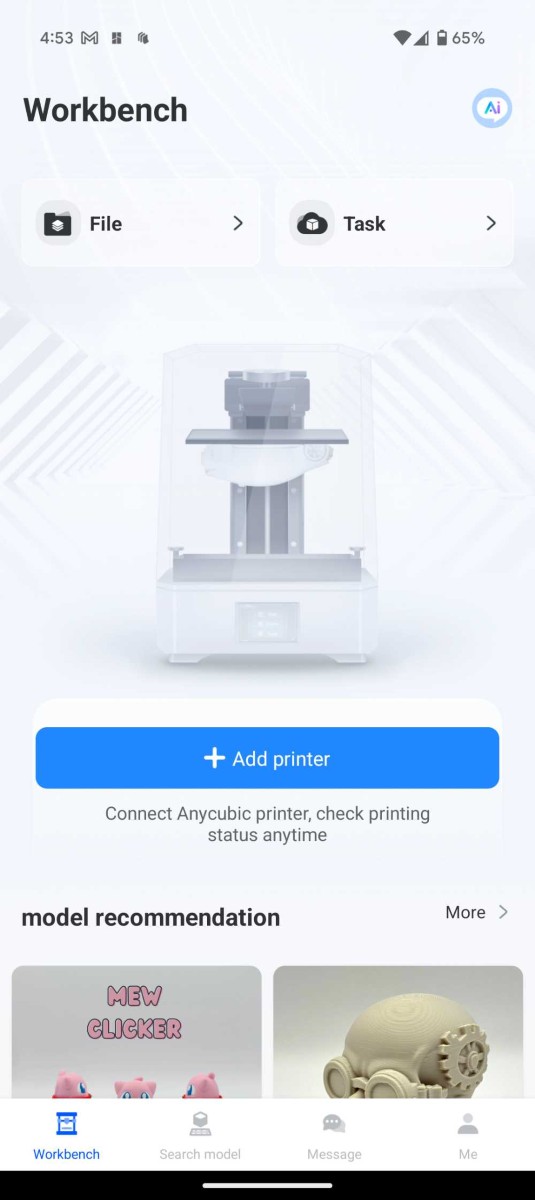

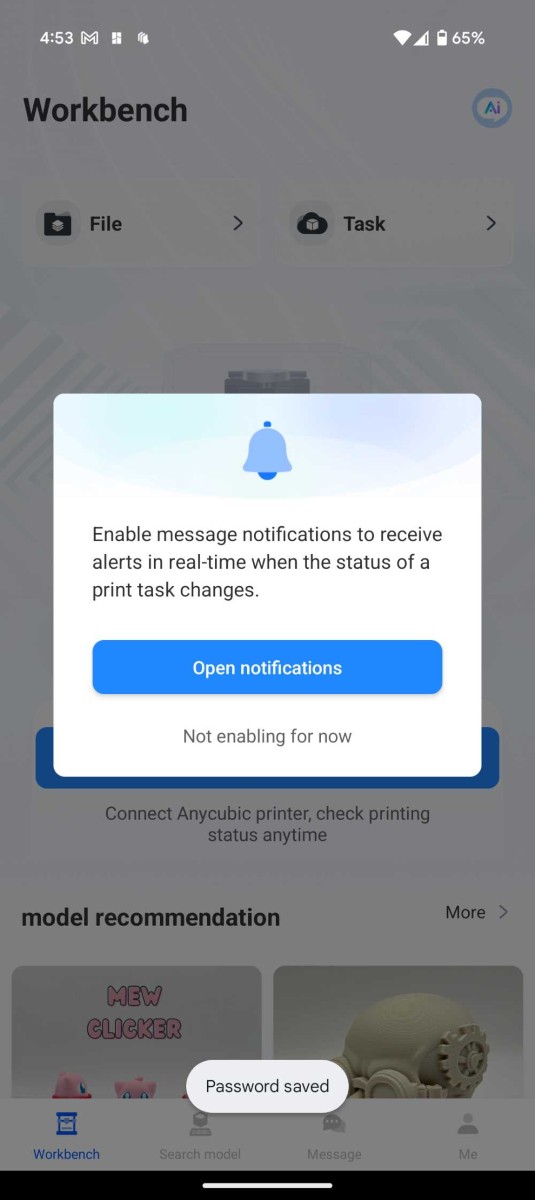

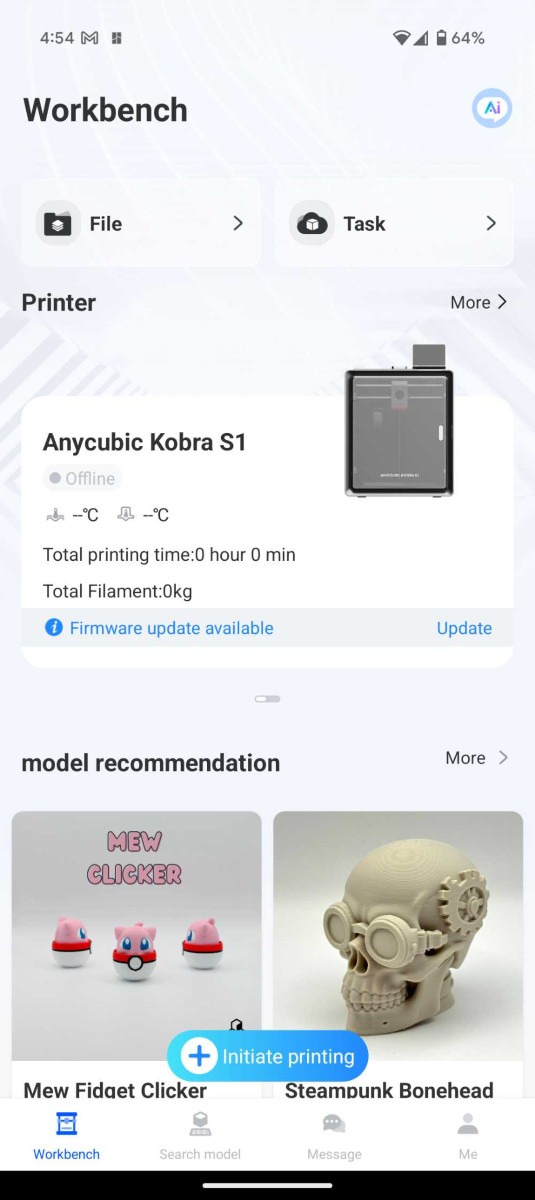

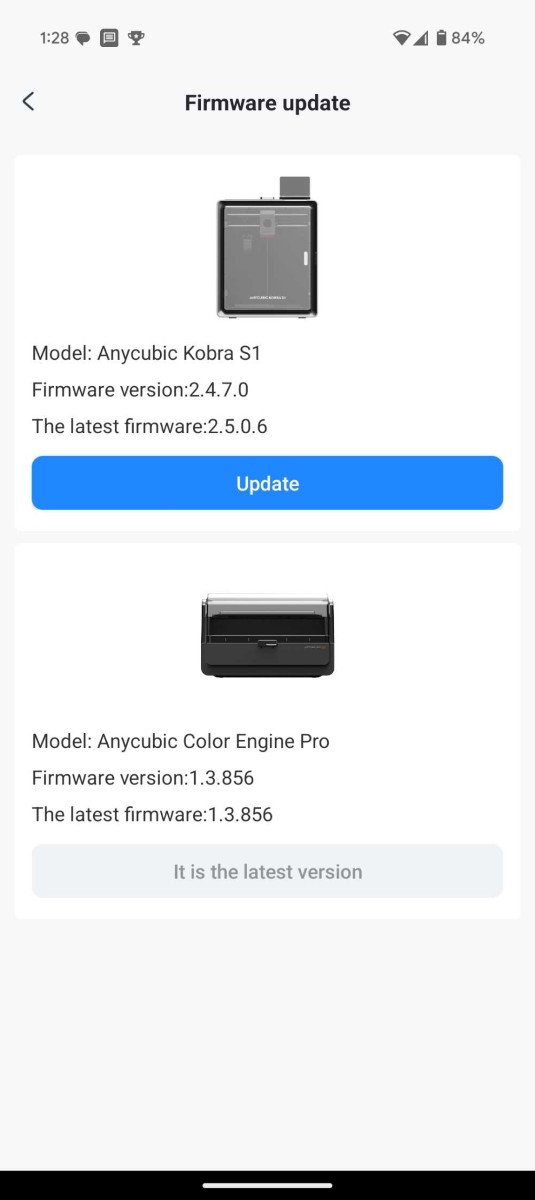

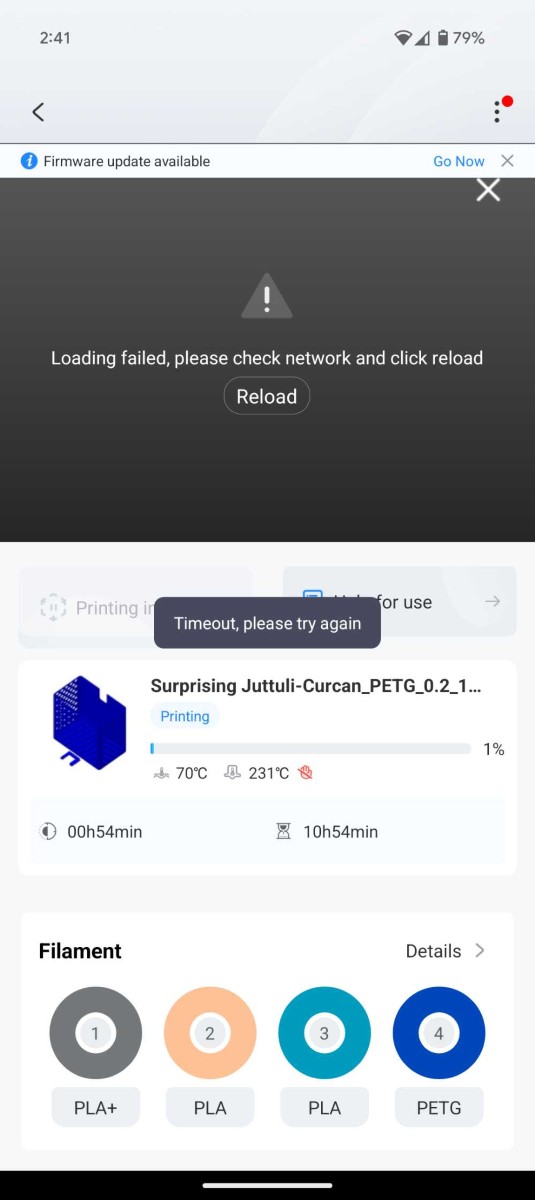

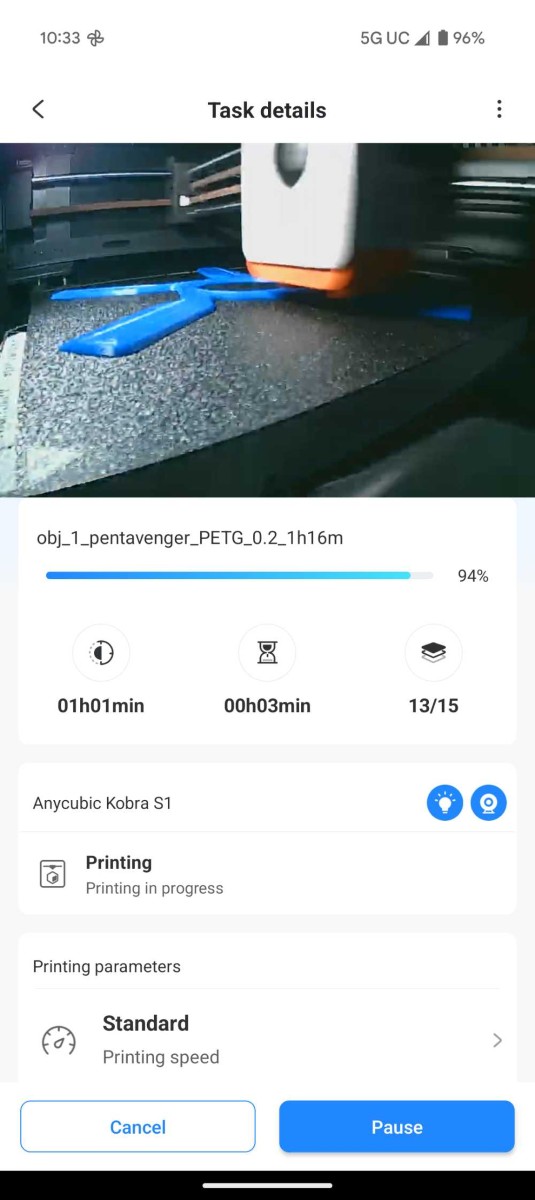

The control screen is a nice size and is easy to navigate and use. Turning on the drying feature on the ACE Pro is quick and easy, and it continues to run while you’re printing! There was no annoying lag or freezes like I’ve encountered with other machines in the past. You can adjust anything you’d need with your printer through the various menus. Here are some screenshots of the mobile app (tested on Android):

The mobile app was fairly intuitive as well, but I did receive frequent “timeout, please try again” messages when attempting to check the camera (both on my WiFi network and through 5G away from home). You can search through Anycubic’s 3D model library and send files straight to the printer from mobile, though for most users you’ll just be using the app to check on the printer and do your actual slicing and sending from a desktop/laptop computer.

Assembly, Installation, Setup

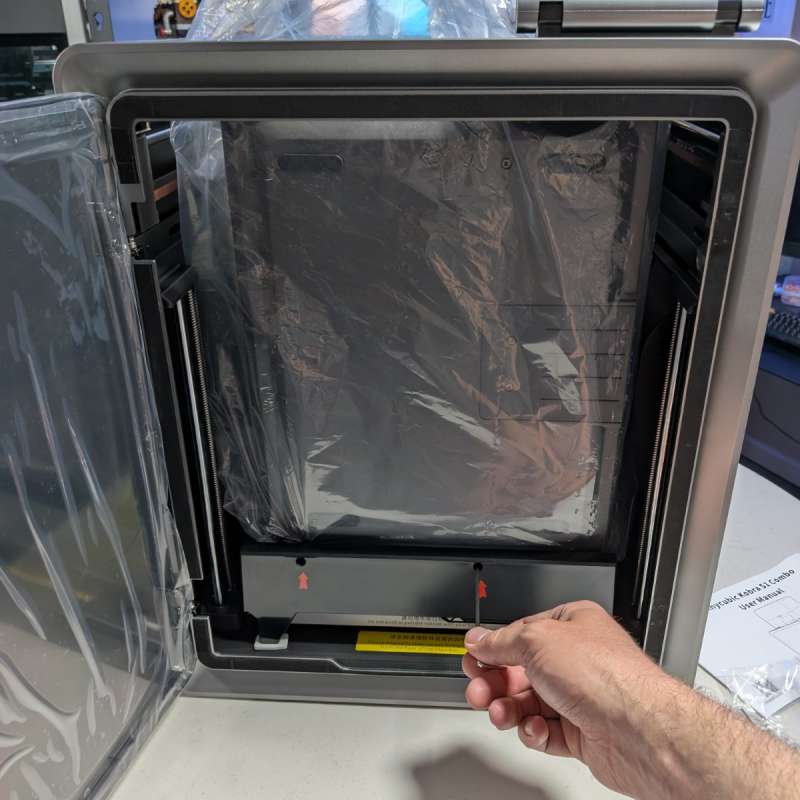

Installation on the Anycubic Kobra S1 3D Printer combo was pretty easy. An included setup guide walks you through the steps, and large red arrows make it easy to find the bolts to remove for each step.

The ACE Pro unit was secured by bolts, as was the heatbed.

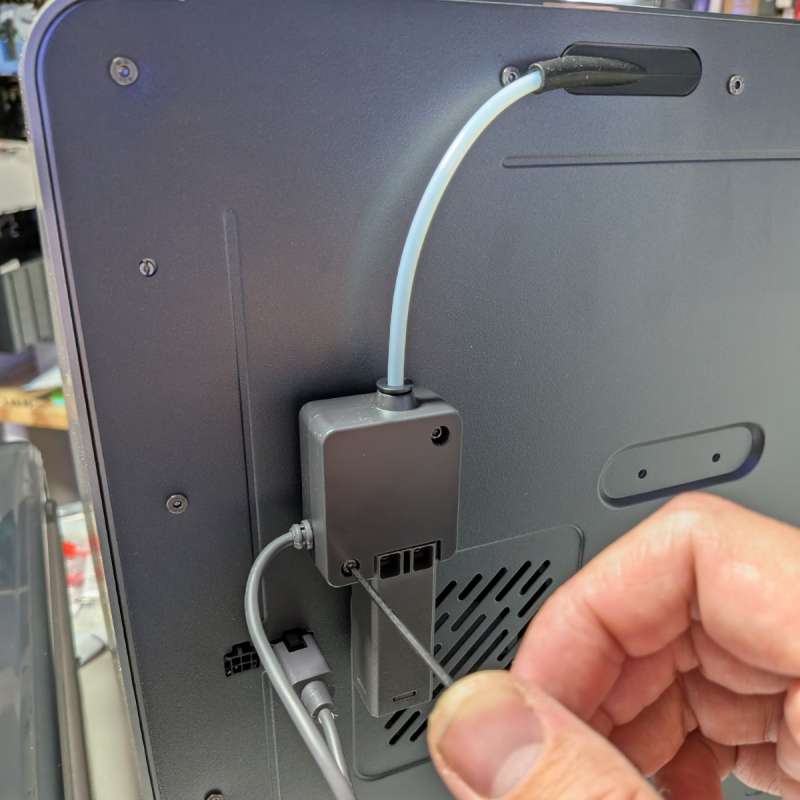

Next, the filament buffer and PTFE tubes are installed. Finally, a power cable has to be connected to both the printer and to the ACE Pro (you’ll need two AC outlets for the combo).

An included activated charcoal bag is stuffed into a compartment at the back of the printer to reduce harmful VOCs and fumes, which I appreciate.

Finally, when powered on the printer itself walks you through the final steps. It performs auto-levelling, and calibrates vibrations to optimize performance and reduce noise while printing.

I then printed out a “Benchy”, and it was on par with the many other printers I’m currently running in my farm, even without any fine tuning. There was a bit of stringing, but I don’t worry about that unless it globs up and interferes with the print (light wispy strings like the ones you can see below are easily blown away by a heat gun after printing).

Performance

I tested out at least 10 different designs during my review period with the Anycubic Kobra S1 3D Printer combo, including tiny multicolor sloths and a large waste bin to collect the purged plastic from multicolor printing.

I was impressed with the quality and speed of the Anycubic Kobra S1 3D Printer combo from the first print, and had no issues with models that have had adhesion issues with my other printers (the included plate has a sandpaper-like texture that grips quite well during printing). I did zero calibration besides the built-in automatic features offered by Anycubic in their slicer.

Speaking of the slicer, it was very familiar since it’s based on Orca Slicer (which in turn is based on Prusa Slicer), so a lot of the settings and interface are what I’m already used to. My only minor complaint with the slicer is that it seems to be slower than the other ones I’ve used in the last few years.

The only print issue I ran into was with some old PETG that decided to break off inside the print head. This lead to a fairly intricate surgery in order to repair the printer:

This repair took a couple of hours and I had to lean on Anycubic support to get the replacement part needed. They got it to me in about a week and a half (shipped from China), and after that repair all was good for the rest of the review.

Final thoughts

I wasn’t expecting the Anycubic Kobra S1 3D Printer to perform as well as it does for the price they’re asking. I love the ability to dry-while printing (especially for PETG stuff) with the ACE Pro unit. I’ve slotted this printer onto a shelf in my print farm, and wouldn’t hesitate to add more of these in the future if I need to expand (especially if they’re on sale).

What I like about the Anycubic Kobra S1 3D Printer combo

- Fast printing with good quality

- Being able to dry filament while printing is very nice – especially for hydrophilic filaments like PETG

- Use of plastic exterior and windows to keep the cost down is a big plus for me – I’m less worried when handling those panels than the glass ones on my other printers.

- Price is good – especially if it’s on sale

What needs to be improved?

- Print head isn’t the easiest to work on (though it’s not the worst either)

- Remote monitoring is flaky – often failed to load

Price: $749 (on sale for $599 at time of review)

Where to buy: Anycubic

Source: The sample of this product was provided for free by Anycubic. Anycubic did not have a final say on the review and did not preview the review before it was published.

Check out these other reviews!

- Bambu Lab X1 Carbon 3D printer review

- Elegoo Centauri Carbon 3D printer review

- FLSUN S1 FDM 3D printer review