REVIEW – 3D printers just keep getting better and better. The best machine is still likely to be one you already have and know how to use, but if you’re looking for new features or faster speeds, or are just getting ready to drop cash on your first printer, there’s never been a better time. Case in point: TwoTrees has just released the SK1 CoreXY printer, and it’s been my best experience yet.

What is it?

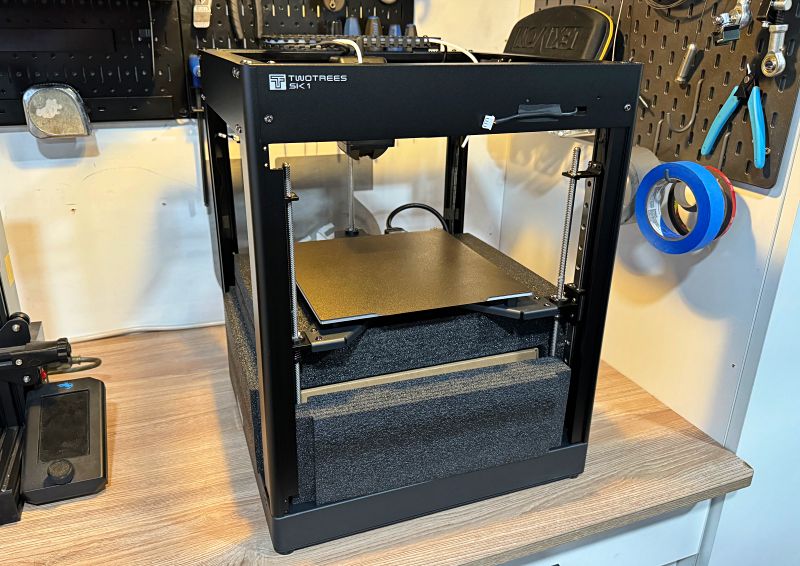

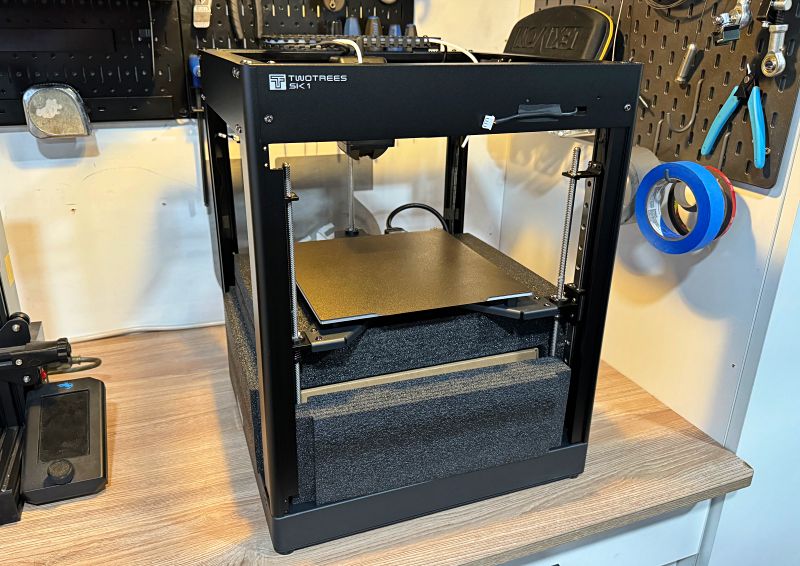

The TwoTrees SK1 CoreXY is a 3D printer that uses the CoreXY motion structure (more on that later). It’s blazing fast at up to 700mm/s, supports WiFi printing, has a large print area of 256mm³ and supports multiple materials.

What’s in the box?

- TwoTrees SK1 CoreXY 3D Printer

- Power cord

- Touch screen and mount bracket

- WiFi antenna

- Assembly manual

- Tools

- Starter roll of filament

- USB-A TF and adapter

Hardware specs

Speed: Up to 700mm/s | 20,000 mm/s² | Flow 32mm³/s

Sizing: Print = 256 x 256 x 256mm | Machine = 400 x 400 x 530mm

Screen: 4.3″ Color capacitive touch screen

Leveling: Z-Tilt + 36 points bed mesh

Firmware: Klipper (open source) featuring input shaping, motion advance and more

Nozzle: 0.4mm diameter, filament diameter or 1.75mm, heats up to 300º F in 30 seconds

Filament Types: PLA | PETG | ABS | ASA | TPU | PC | UltraPA

Extruder: Dual-gear direct extruder

Print: USB, LAN, WiFi | Format = G-Code

Print Bed: Magnetic PEI Plate

Accuracy: Print = ±0.1mm | X/Y/Z axes = ±0.0025mm

OS Support: MacOS | Windows | Linux

Design and features

The TwoTrees SK1 CoreXY is a 3D printer that uses the CoreXY motion structure. That means that the extruder moves on both the X and Y axes. The print bed uses three drive shafts (front left, front right and center rear), allowing it to tilt for automated leveling. A capacitive touch panel enables easy control and maintenance, while a WiFi or LAN connection allows remote web monitoring and extensive reporting.

The print bed is heated (up to 100º) using a magnetic plate but with the small detail of adding rear anchors to guarantee alignment. It just makes things easier, and the texture creates a clean visual on whatever surface you have facing down.

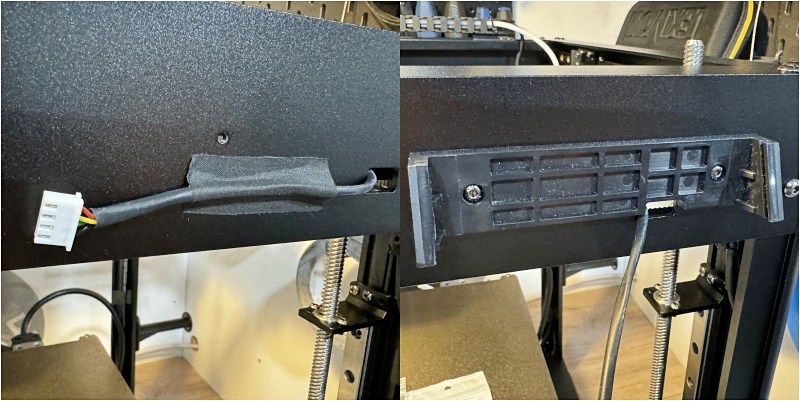

Power and filament to the extruder are already routed through a tank/tread/chain structure keeping everything clean.

A built-in LED inside the front panel illuminates your in-process prints well.

Setup

The TwoTrees SK1 CoreXY 3D Printer arrives almost fully built. The assembly process involves removing a few screwed-in shipping blocks, assembling the screen and securing the drive shafts. There’s a QR code to scan for updated documentation, but let’s walk through it. Start by removing the foam pieces that kept everything stable during shipping.

Next remove these screwed in blocks that kept everything locked down. Install the supplied screws where the blocks were. I believe there were 8 and there were a couple that were not present on my machine.

Install the filament spool hanger on the right side.

Prepare for the screen by freeing the cable and installing the mounting bracket.

Connect the cable to the port on the back of the screen, and then slide the screen down onto the bracket.

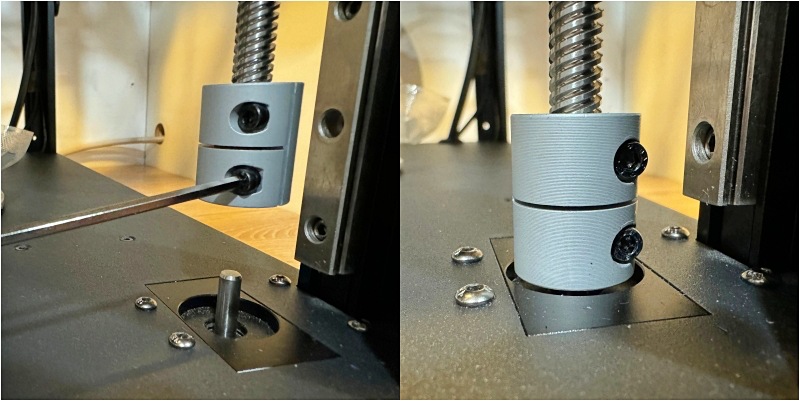

This step had the least guidance. I manually spun each of the three drive shafts until fully lowered to flush with the main surface, but above the recessed floor to prevent direct contact. Then tighten the lower screw with the included hex wrench. Check the upper screw while you’re at it.

Install the WiFi antenna onto the post and we’re about ready to go. On the opposite side, make sure the recessed switch is set to the correct voltage for your country.

Connect the power cord and flip the red switch to power up the SK1. Give it a minute to start up and then navigate to the settings screen to set up a connection to your WiFi. Note the IP address when you see it on the screen as you’ll need that for remote access whether on WiFi or LAN.

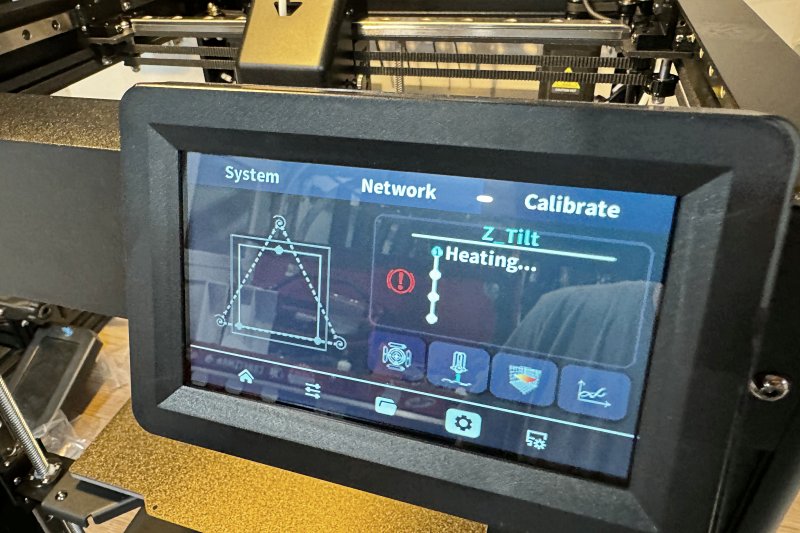

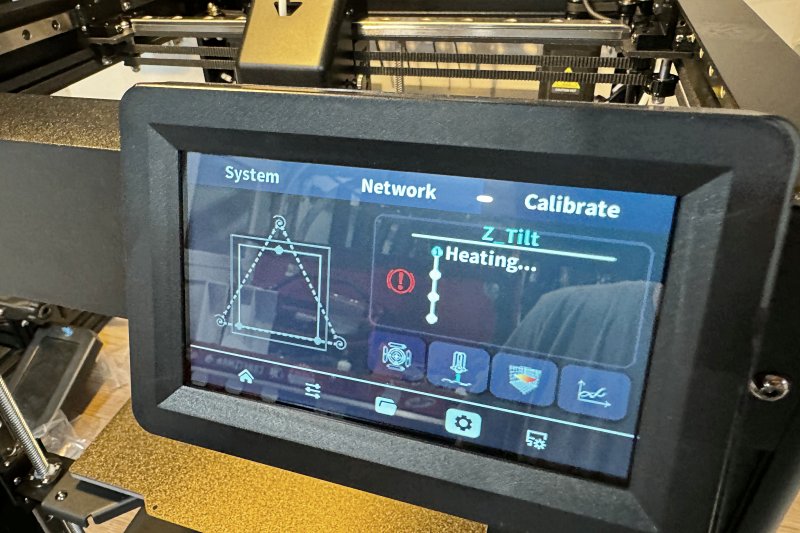

The last step is to calibrate everything. Below is that screen. In order from left to right, you’ll press the icon for each of the following…

Z-Tilt calibration, Probe calibration, Bed Mesh calibration, and Vibration calibration.

All of these are fully automated and will finish on their own with the exception of the Probe calibration. After the heating, it will take 3 probe measurements and then wait for you to calibrate final distance using a sheet of paper and the Z up/down controls. This is pretty straightforward, but keep in mind that the down arrow means moving the probe closer to the bed. That may seem obvious, but because the bed moves up to make that happen it’s easy to get confused. Also the movements are in 0.2, 0.1 and 0.02mm increments, which are small, and the bed moves away and then closer with each adjustment, so it can sometimes feel like it isn’t getting closer. Just start with 0.2 and go slowly, switching to finer movements as you get close. Stop when you feel a small amount of drag on the paper as you pull.

Install the filament reel onto the hanger and begin to feed the filament into the tube until it stops. The built-in lights should flash twice at this point. On the screen, navigate to Controls (one to the right of the home icon) and then choose load/unload, and press the load button. The extruder should begin to pull the filament. If not, you may need to push the filament manually and/or check for any hard angles in the tubing that are preventing the filament from sliding smoothly. The extruder will take over and run about 15 seconds of filament and then you are ready.

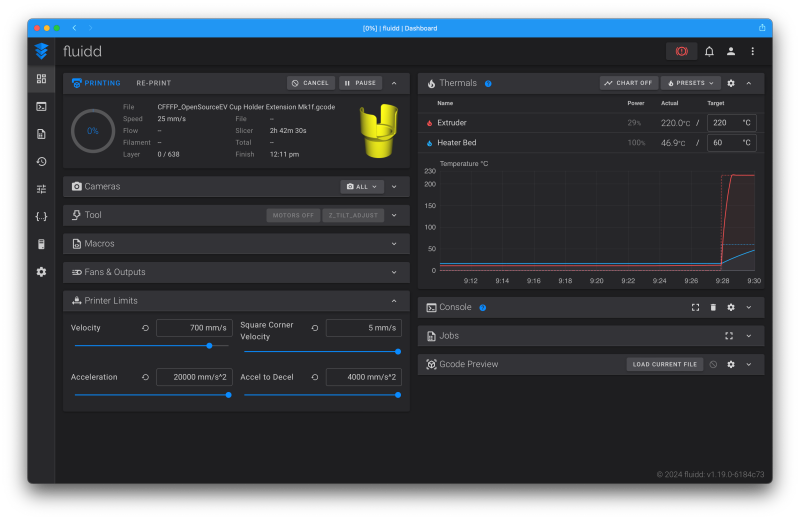

The last step is to open a browser on your computer and type in the IP address noted earlier. When you hit return, you’ll be presented with their web interface called Fluidd. Here you can monitor and control almost every aspect of a print project.

Performance

My experience with consumer 3D printers has been limited to two models by Creality. The Ender 7 (also a CoreXY), which I reviewed two years ago, and the Ender 3 Pro, which I bought for myself after letting my son run off with the Ender 7. I got pretty comfortable with the 3 Pro but was looking for more features.

The TwoTrees SK1 CoreXY 3D Printer is a perfect upgrade for me. It has a print bed that’s an additional 20mm in both the X and Y axes, but for me, the biggest improvements were the speed and remote abilities. Being able to use my slicer of choice (Cura), and then send it directly to the printer with a start print command, is awesome. Note that this does require the printer to be on.

Both the bed and the extruder heat quickly and hold temperatures accurately. The trickiest part (as usual) is discovering the best temps and settings for each material you’re going to use. Find a good temperature tower to print and get in the habit of printing one for each new material. It’s also been colder than usual here and since my printer is in the garage, I’ve had to make a few adjustments for that as well.

I ran into very few issues. I had to slightly tighten the belt tension as I had a couple slips in the first benchy build. The display seems to lock up occasionally on longer builds and is only corrected by a restart. I’m hoping there will be a screen firmware update to fix that soon. It’s only been launched recently, so I would expect to see some updates over the next couple of months. I also noticed that all the sides have a recessed area with tapped screw holes to accept plexi panels. I don’t know if that’s in the works or not, but I’ll probably laser cut some myself to help temperature and humidity control in my garage.

As far as materials go, I usually stick with a PLA or PETG. TwoTrees sent along their high-speed PLA that was remarkably consistent. Here’s a high resolution print of the moon that I tested with. The detail was impressive.

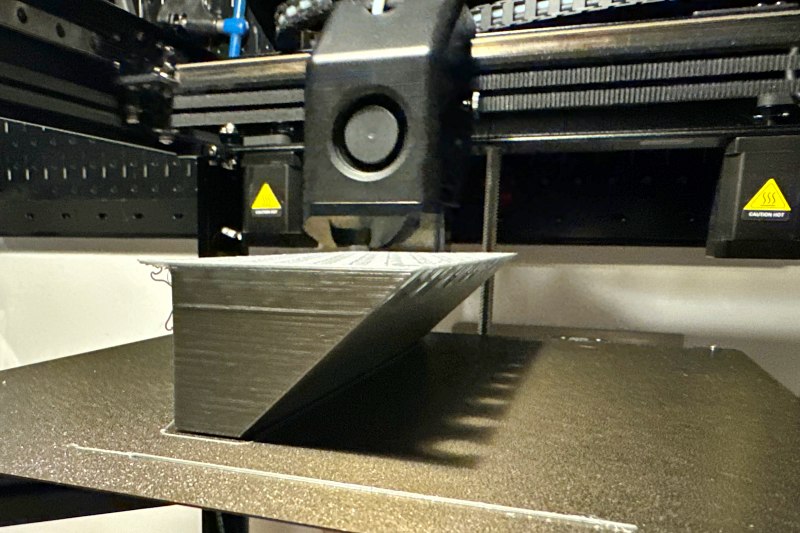

The heated bed also did a really good job of supporting some prints with large overhangs without support structure, like this earlier attempt at a Hex Wrench holder I designed in the Shapr3D app for iPad.

Here’s the revised print to use less material and angle the wrenches out.

I also printed some filament bearing rollers compatible with the IKEA skadis grid. They came out like this.

Here’s a video of those in process where you can see the speed, accuracy and get an idea of the machine’s sound.

And finally a Benchy for your reference. Very clean and very fast.

What I like

- Super fast and consistent prints

- Larger print sizes of 256mm³

- WiFi printing and management

- Built-in lights

What I’d change

- Better assembly and use instructions

- Touchscreen occasionally becomes unresponsive requiring a restart

- WiFi occasionally drops out where remote control panel cannot connect

Final thoughts

At a full retail price of $599, the TwoTrees SK1 CoreXY 3D Printer is easy to set up, and it’ll have you printing successfully in no time. While the instructions can be a bit vague, they’re enough to get you started, and the web interface provides more control than most users will need. Find your favorite slicer and get after it.

Price: $599 – Currently at $499 unbundled with US Plug

Where to buy: TwoTrees

Source: The sample of this product was provided by TwoTrees.