REVIEW – I’ve reviewed quite a few 3D printers so far at The Gadgeteer, but many of the items I print take all day (or even multiple days for things like full-sized helmets). What can I say, I like big … things. But what if you could speed a 3D printer up to five times faster than your usual FDM 3D printer? There’s a handful of newer entries to the 3D printer market that boast print speeds of 300+ mm/s (typical FDM 3D printers are usually 50-80 mm/s), and the Geeetech THUNDER High Speed 3D Printer is now one that I get to try out!

What is it?

The Geeetech THUNDER High Speed 3D Printer is a Fused Deposition Modelling printer, which melts spools of plastic and deposits the melted goo layer by layer to create whatever 3D model/figure/part you’ve designed or downloaded. It can print a variety of materials like PLA, PETG, ABS, and TPU. The biggest differentiator between most other 3D printers though is the speed, the reinforced chassis, stronger motors and extra fans allow for 300 mm/s+ prints.

This speed is great, especially for makers who are working on projects and need to rapidly produce parts to prototype. The ability to crank out 3D prints in minutes instead of hours can result in much faster workflows that previously required industrial 3D printers costing magnitudes more to achieve.

What’s in the box?

- Geeetech THUNDER High Speed 3D Printer

- Touchscreen

- 2x T-shaped reinforcement plates

- Shovel/scraper

- SD card

- USB cable

- Replacement Teflon tubes and zip-ties

- Filament holder

- Toolkit (wrenches, hex wrenches, nozzle cleaner needles

- Install screws

- Spare 0.4mm nozzles (x2)

- Test high-speed PLA filament

- Quick-plugs (for teflon tubes)

- Manual and service/warranty cards

- Bed levelling kit

Hardware specs

- Print volume: 250x250x260mm (x,y,z)

- Max Printing Speed: 270 mm/s

- Filament Diameter: 1.75mm

- Max Nozzle Temperature: 250℃

- Max Hotbed Temperature: 110℃

- Supported filaments: PLA, PETG, TPU, ABS

- Max Acceleration: x=5000mm/s²,y=4000mm/s²

- X/Y Closed-loop control, Z axis silent driver

- Display: 3.5″ color touchscreen

- Filament runout detection: Yes

- Extruder: Dual gear direct drive high speed

- Fans: 6 x various fans

- Levelling – auto and manual

- Power outage resume: yes

- Machine size: 472(L)*488(W) *525(H)mm

- Weight: 10.7 kg

Design and features

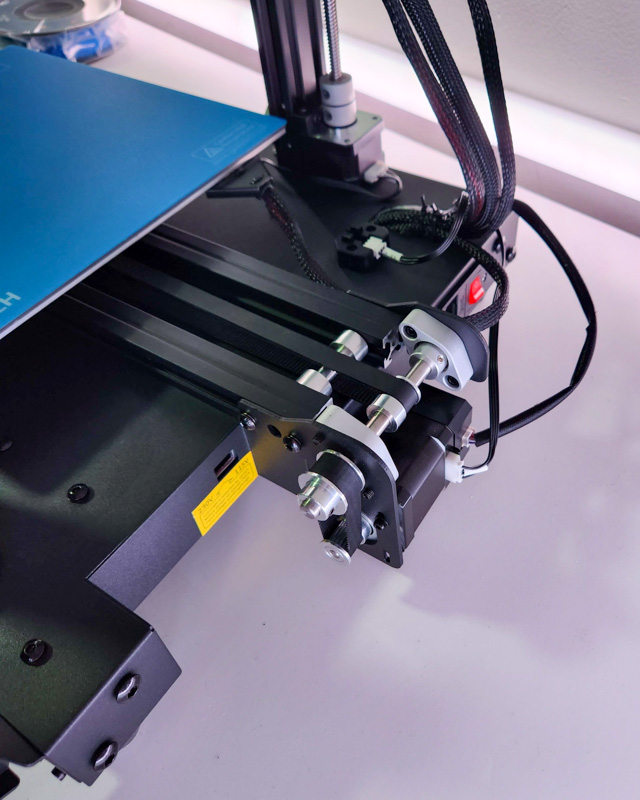

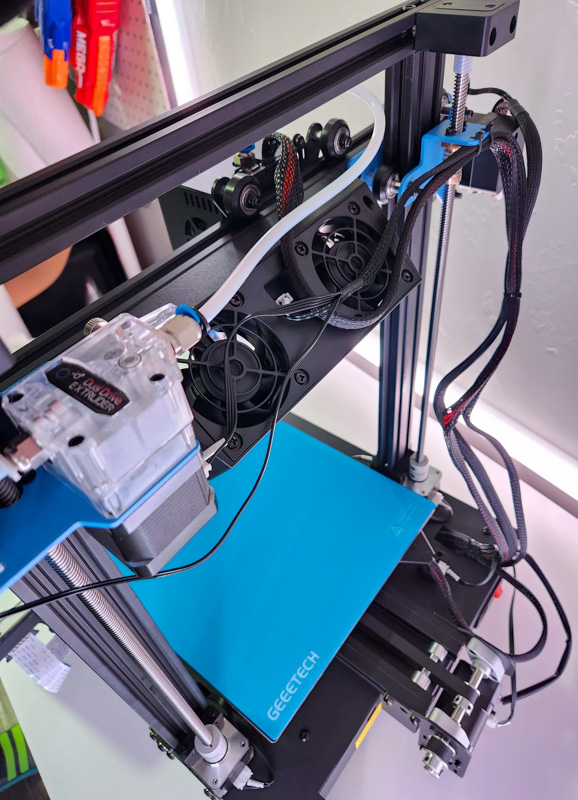

The above shot of the back of the Geeetech THUNDER High Speed 3D Printer gives you a good idea of the build quality from the start, everything seems built like a tank. The entire body and gantry is metal and solid. The Y-axis motor is specially designed for both speed and to dampen vibrations (caused by speedy movements) so you don’t lose quality despite printing fast.

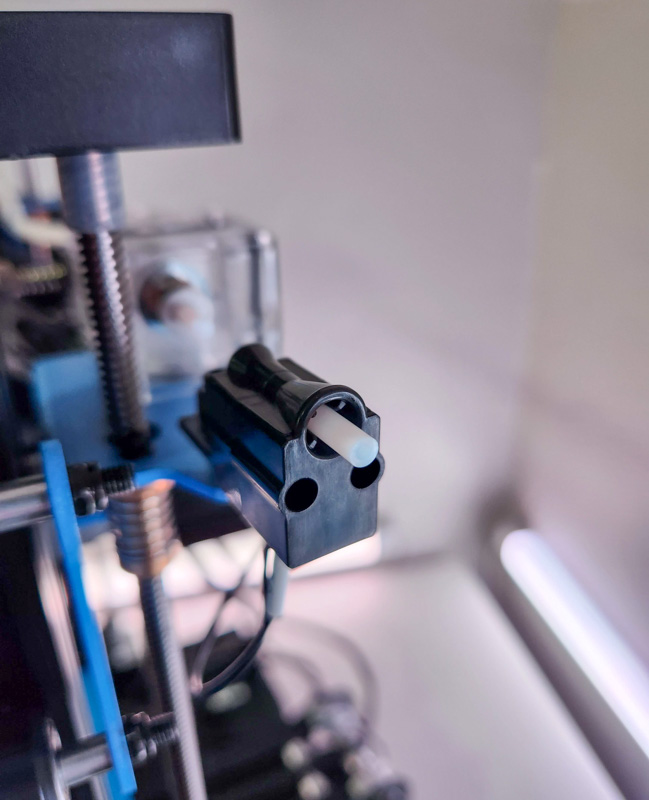

The nozzle and hotend are hidden under a cover that also houses two high speed fans (with 3D printed fan ducts directing the airflow right onto the freshly oozed plastic!).

I didn’t even notice that these fan ducts were 3D printed until processing these photos to put into my review. There’s also a white LED light that can be turned on to illuminate your print and notice the two holes and data port on the front – ready for the auto-leveling system to be installed.

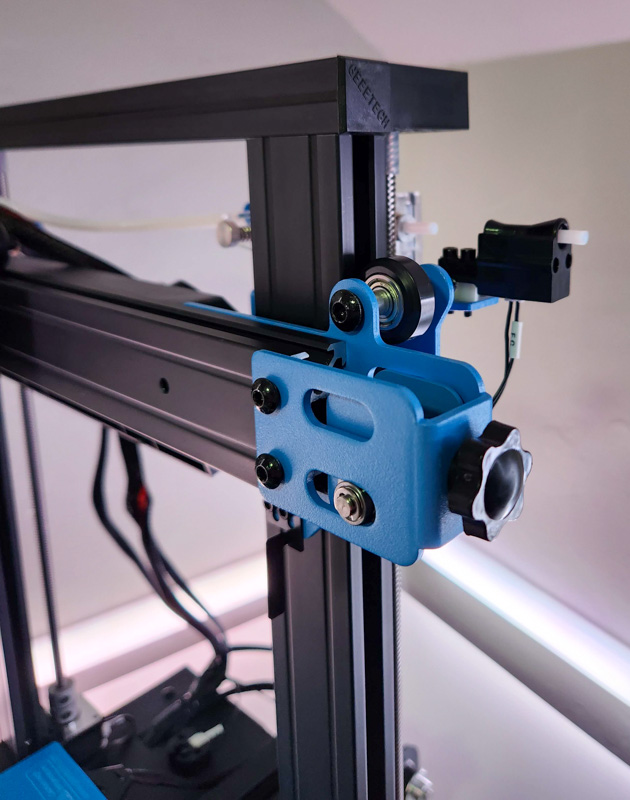

The gantry is all very solid, and you can see the knob on the far right in the picture above – this allows for easy control of the belt tension. Knobs are available for all axis to adjust tension (much nicer than adjustments requiring a wrench).

Moving a bit further back is the filament sensor – this stops printing if the filament breaks (though I had it break once after the sensor but before the extruder, so most of a model didn’t print at all since the machine thought it had filament and was printing but was just moving through empty space).

Speaking of filament, it hangs on the spool holder to the right of the machine. This is a pretty standard affair, no complaints here. I prefer the side option because I can remove it and use a filament dryer instead, allowing for the filament to stay nice and dry right until it’s pulled into the machine for printing – this is a bit harder to set up on top-mounted 3D printers.

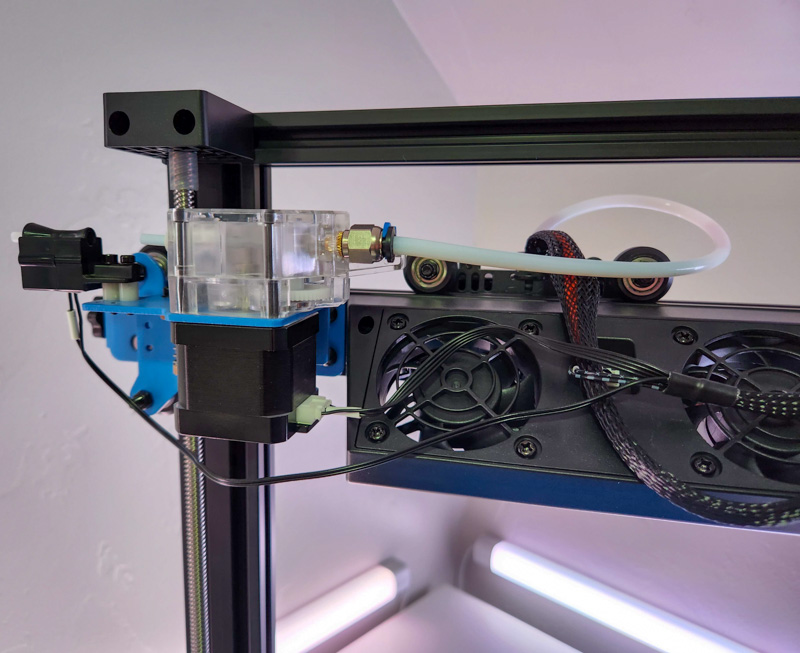

Moving around to the back of the Geeetech THUNDER High Speed 3D Printer you can see the Bowden extruder and extra fans. Based on past experience I usually prefer direct extrusion systems (extrusion gears in the print head), but for speed the Bowden setup allows the print head to be lighter and faster. I also had none of the issues that have plagued me with past Bowden extruder systems like excess clogging and stringing issues due to slower retraction – it seems Geeetech’s dual-gear setup works great here.

Above is another shot of the back looking down.

The front of the machine has two USB connections (one for USB-A drives to be inserted with printable gcode models on them, and the other for direct control by a computer) and a micro-SD slot. When printing, you can choose either the USB drive or SD slot to select models from. Also, notice the heavy duty drive belt and reinforced Y axis assembly, again with an easy knob for tension adjustments.

The print bed itself is a rubbery coated flexible plate that can be pulled right off the heatbed (magnetic). This is by far the grippiest print surface on any FDM 3D printer I’ve used, the first few test models I tried to get off were seemingly glued to the bed and required a lot of cursing and jabbing to remove, sometimes in pieces. Be smarter than me and read the manual, you’ll discover that Geeetech recommends heating the heatbed an additional 20 degrees C or so after printing and then scraping the print off. This worked perfectly every time after I discovered that.

The extra grip is crucial for the speeds at which this printer operates I’m sure, but I also like that I’m not worried about a print failing from bed adhesion at all with the Geeetech THUNDER High Speed 3D Printer.

Setup

Setup is very similar to most of the other FDM 3D printers I’ve used so far: carefully position the top gantry over the base and then insert and tighten screws from the bottom.

However, after the bottom screws, you’re instructed to install these T-shaped plates to reinforce the already beefy structure even more. Did I mention this thing is built like a tank yet?

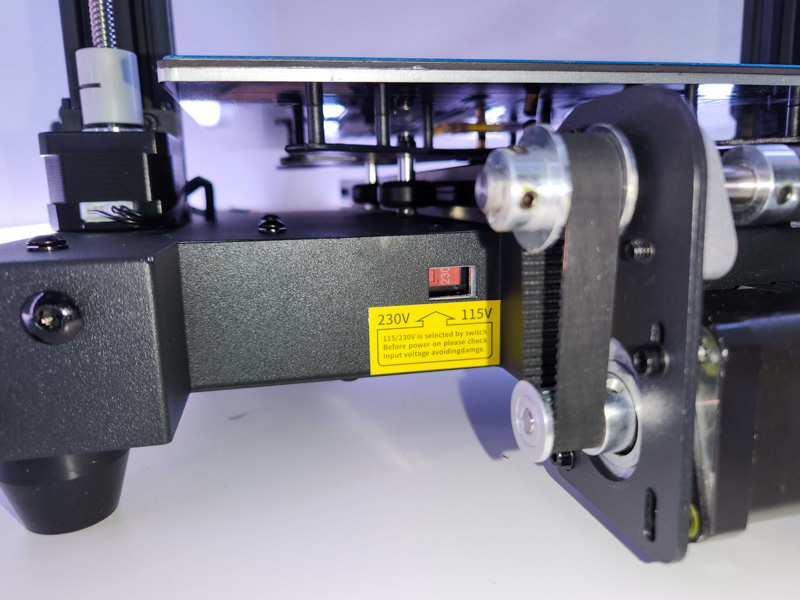

It’s very important to check the voltage setting on the back, it was set to 230V as sent to me, you’ll want to verify it’s at the correct setting for your outlets.

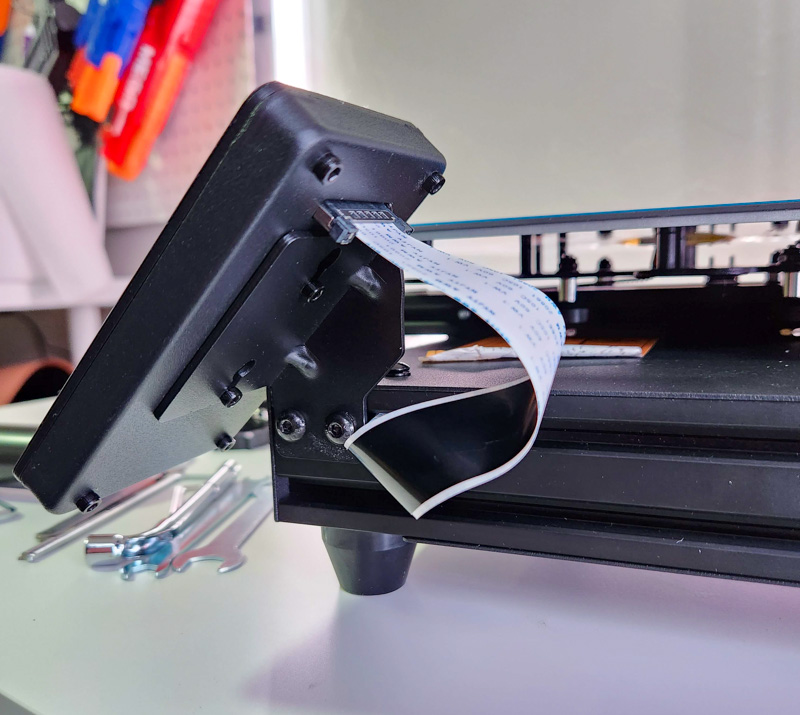

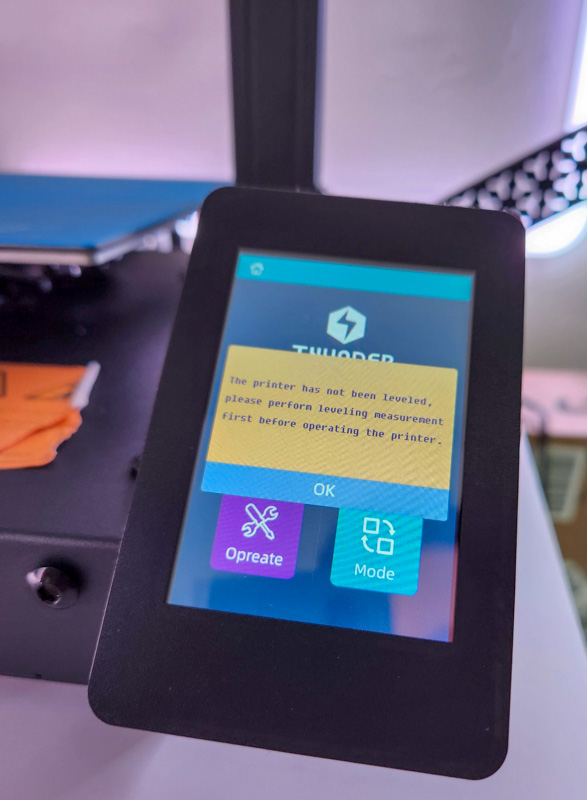

Installing the touchscreen is as simple as a couple of screws and attaching the ribbon cable. You’ll also need to install the auto-bed-leveling kit, this just takes a couple of bolts and nuts and attaching a cable to the print head.

Upon first power on, the touchscreen invites you to auto level, which I did:

I checked manual leveling after performing the auto-level, and didn’t need to adjust any spots, it was great.

At this point, you’re ready to print! There are a couple of test models right on the included micro-SD card, or you can design your own 3D parts using a CAD program, then you’ll need to “slice” the 3D model to convert it to 3D printer language (known as GCODE). I used the latest version of Ultimaker CURA, which included built-in profiles for the Geeetech THUNDER High Speed 3D Printer.

Included is a small sample of high-speed PLA filament. You can also print regular PLA, ABS, TPU, and PETG (and any other filaments with similar heat requirements), but be aware that filaments should specifically say they’re rated for high-speed if you want to use the Geeetech Thunder’s speed. If using a non-high-speed filament you should set the print speed to 80 mm/s or slower depending on the filament.

Performance

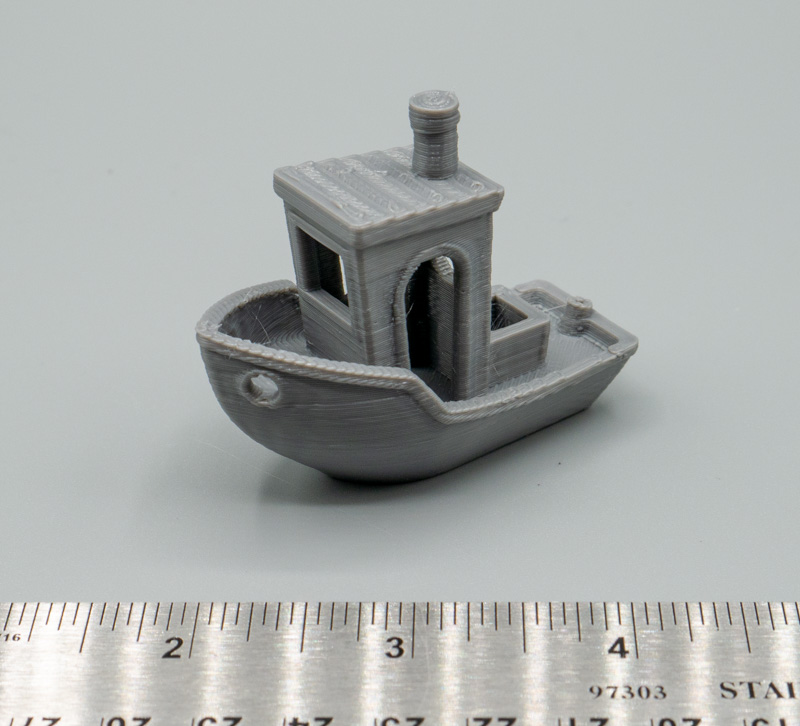

I knew the Geeetech THUNDER High Speed 3D Printer would be fast based on other videos I watched, but seeing it in person was shocking to me, someone who’s used to printing most things 5-10x slower.

The above Benchy was printed in just over 20 minutes (usually takes about ~90 on my other printers). While there are some flaws, it’s better than most first Benchy’s I’ve printed, and with a bit of calibration would rival most other printers even at high speed.

Calibration prints and a flexi-shark also printed out remarkably quickly, while trading blows quality-wise with the previous printers I’ve tested.

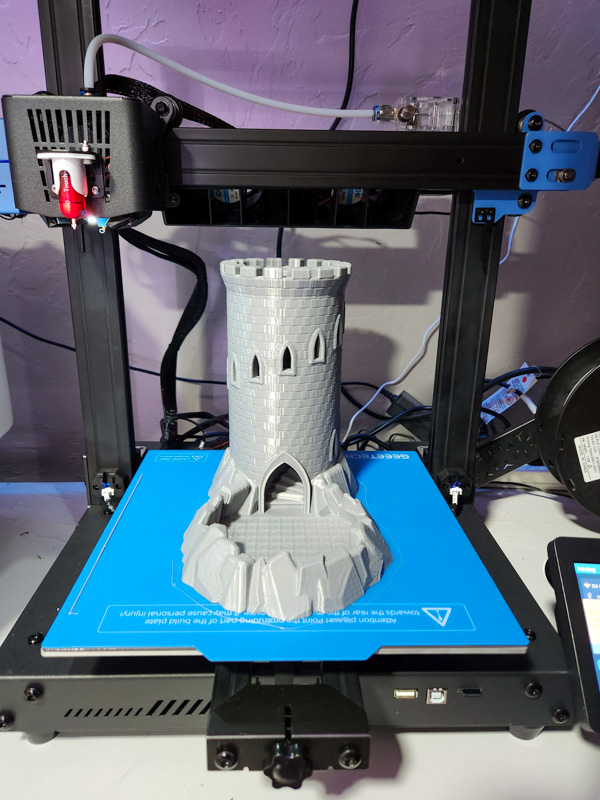

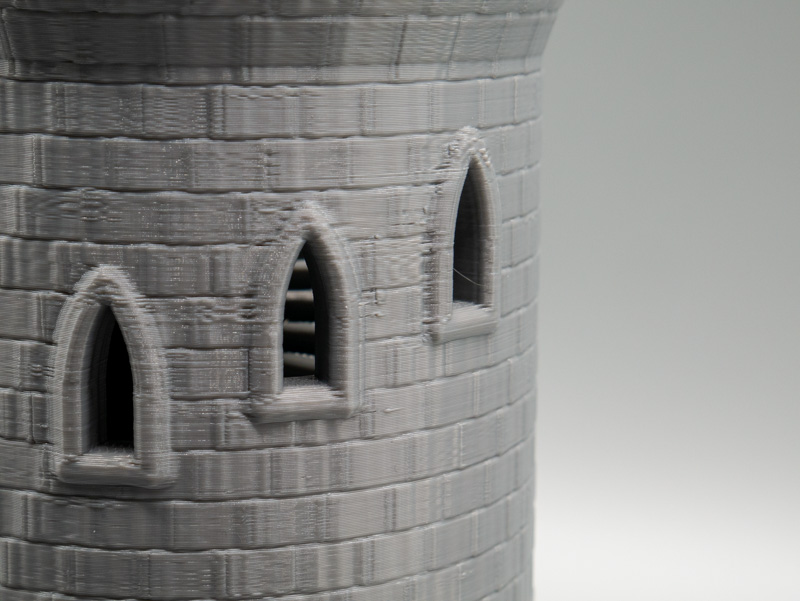

I decided to give the Geeetech THUNDER High Speed 3D Printer a real challenge – a large dice tower printed at full speed. Again, it printed in a fifth of the time other printers can do and overall had great quality.

You can see some of the minor flaws when zoomed in above, but some of it may have been day-old PLA that wasn’t in a dryer rather than anything related to the speed or accuracy of the Geeetech THUNDER High Speed 3D Printer. I had very little stringing even before calibration using Geeetech grey high-speed PLA.

What I like

- Good quality even at high speeds

- High print speeds

- Very sticky print bed

What I’d change

- Loud fans – would benefit from an enclosure just for the noise (would be safer as well)

- New models hitting the market are competitive in price and speed, like Creality’s K1 Speedy

Final thoughts

If you’re looking for a fast printer, the Geeetech THUNDER High Speed 3D Printer is a solid option. I was impressed throughout the review by both the speed and quality of the prints. If competitors weren’t dropping similar printers right now (like Creality’s upcoming K1 Speedy), it would be almost unrivaled in the market, but it’ll soon have healthy competition, which is good for us consumers. All told, this is a great addition to my 3D printer farm, and will be especially useful for rapid prototyping parts (whenever I print something to use around the house, I always end up printing 3-10 versions as I realize which dimensions or angles I measured wrong).

Price: $699.99 (on sale for $489 at the time of review)

Where to buy: Geeetech and Amazon

Source: The sample of this product was provided by Geeetech