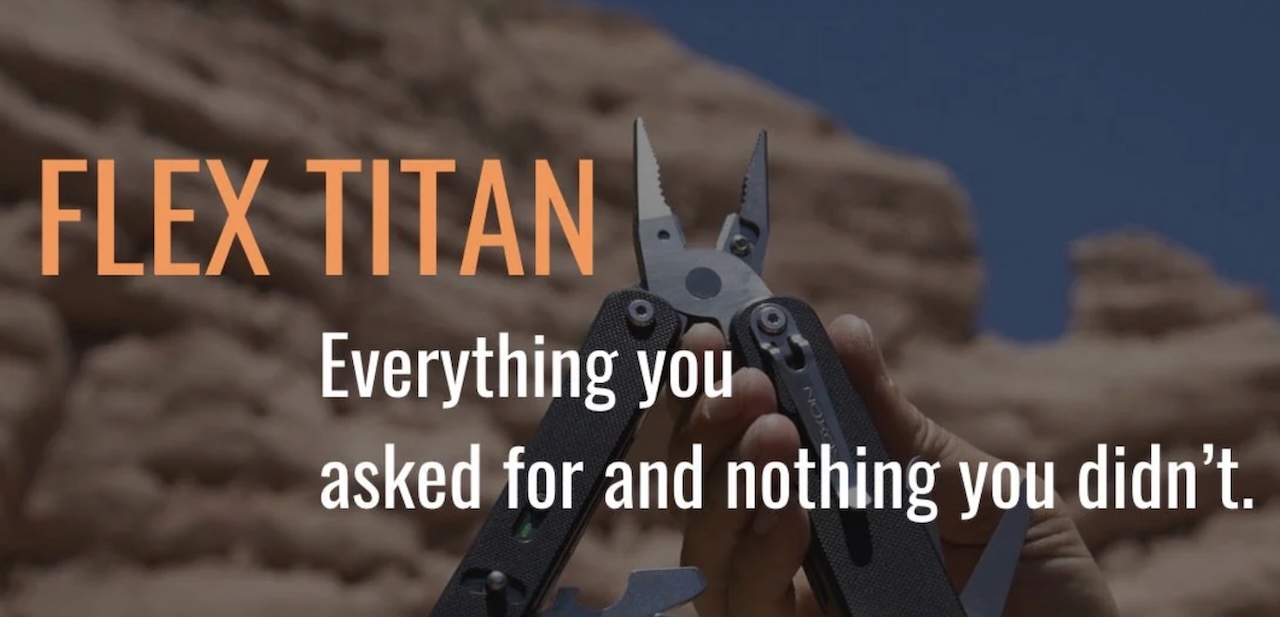

Roxon has announced the Flex Titan, a plier-based multitool that taps into two separate modular ecosystems simultaneously. It’s the company’s most robust modular platform to date, built for users who’ve been requesting something tougher than Roxon’s current lineup.

Price: TBD

Where to Buy: Roxon

The tool launches later this month with reinforced construction and dual compatibility with both Flex and Phantom Blade systems. What sets the Titan apart is how it combines Roxon’s hook-to-bar Flex system with its button-lock Phantom Blade system on one chassis, giving users access to 55 Flex implements plus 17 Phantom options. Most modular multitools force you to pick one ecosystem. The Titan lets you use both, which means you can swap out blades, drivers, saws, and specialty tools without carrying separate platforms.

Why Two Systems on One Tool

Roxon’s been building modular multitools for a couple years now, but the Titan pushes the concept into heavier construction. The Flex system uses hook-to-bar attachments that let you swap implements quickly without tools or hardware.

The Phantom Blade system swaps knives and small tools through a button-lock mechanism. You flip two locks, pull off a handle plate, drop in the new blade. It’s simpler mechanically than Flex and designed specifically for knife customization rather than full tool replacement.

Running both systems on one platform expands adaptability beyond what single-ecosystem tools offer. You’re not stuck with a fixed blade profile or a predetermined implement set. You stock what matches your work, and the tool morphs around it.

That flexibility comes at the cost of added complexity and weight, but for users who actually swap tools in the field rather than in their garage, the trade-off makes sense. The dual system means you’re carrying more hardware, but you’re also eliminating the need for multiple separate tools.

Design and Construction

The Flex Titan ships with needle-nose pliers featuring wire cutters, two straight blades, small scissors, a saw, a ruler, and a bottle opener. That’s the base configuration before any modular swapping happens.

Unlike Roxon’s existing stainless steel modular tools, the Titan features texturized G10 outer panels. The material is commonly used on higher-end folding knives for its durability and grip properties, particularly in wet conditions. G10 adds both functional grip and visual differentiation from Roxon’s previous bare-metal designs. The texture catches your palm differently than smooth steel, which matters when your hands are wet, oily, or gloved.

Roxon says it applied thicker materials and structural reinforcements throughout the chassis to handle high-torque tasks without loosening bolts or failing at pivot points. Exact specifications haven’t been released yet, but the company designed the tool specifically for demanding use cases: off-road work, wilderness survival, overlanding, and professional trades where tool failure isn’t an option.

The Flex Ecosystem Explained

Roxon’s Flex ecosystem currently includes 55 swappable implements. Options span blades, saws, screwdrivers, hex keys, fire-starting flints, bicycle spoke wrenches, and task-specific tools like angling implements.

Hook-to-bar attachment means you swap tools quickly without additional hardware. That’s important because fumbling with screws or clips defeats the point of modular design. If your needs change mid-task, you rebuild the tool in seconds.

The practical advantage of modular is that you’re not carrying five separate tools. You carry one chassis and a selection of implements that match your expected tasks.

Weight savings matter when you’re backpacking or managing limited vehicle storage in an overlanding rig. Trail work shifts to camp maintenance, day hike turns into an overnight repair job, whatever the situation demands.

Roxon’s been refining the Flex attachment mechanism since it launched the system. Early versions had issues with implements loosening under heavy lateral load, but the company addressed that in later iterations. The Titan uses the latest version of the hook-to-bar system with thicker engagement points.

Phantom Blade Integration

The Phantom Blade system offers 17 options, primarily blades and saws, plus a file, comb, and 10-in-1 multitool that includes a seatbelt cutter, ruler, can opener, and hex wrench set.

Swapping requires flipping two button locks, removing a handle plate, and installing the new blade. The button locks feel more secure than friction-fit systems. That’s important when you’re putting pressure on a blade edge during cutting tasks.

The locks prevent unintended blade release, which is a failure mode that cheaper modular tools sometimes suffer from. This matters more than you’d think when you’re working with force.

Phantom blades are simpler to swap than full Flex implements because you’re only replacing the knife component rather than an entire tool assembly. A hunter might carry a gut hook blade, a skinning blade, and a fillet blade on the same chassis without needing separate knives.

An electrician might carry a standard blade, a wire stripping blade, and a scraper blade. The system works for any profession that needs multiple blade profiles but doesn’t want to juggle separate handles.

The Phantom system accommodates that kind of task-specific blade rotation without forcing users to carry multiple complete tools. It’s narrower in scope than Flex but deeper in its specific category.

Who Actually Needs This

Roxon developed the Titan in response to customer requests for a larger, more durable modular platform. The company is targeting users who need heavy-duty capability in harsh environments: off-grid wilderness trips, professional trade work, and overlanding scenarios where space is limited but tool versatility matters.

This isn’t meant for casual everyday carry. It’s meant for users who actually stress-test their multitools and have encountered cheaper tools that bend, wobble, or fail under real workload.

The target user is someone who carries tools professionally or recreationally and needs gear that holds up when pushed hard. That includes wildland firefighters, search and rescue personnel, outdoor guides, vehicle recovery specialists, and tradespeople who work in remote locations without easy access to replacement tools. If you’ve never broken a multitool, you probably don’t need this one.

Pricing and Availability

Roxon hasn’t announced pricing or detailed specifications yet. The company’s current modular multitools range from $18 to $60, but the Titan’s reinforced construction, dual modular systems, and premium materials suggest positioning toward the higher end of that range or potentially above it.

Price: TBD

Where to Buy: Roxon

Given the G10 handle scales, upgraded internal reinforcements, and compatibility with two complete modular ecosystems, pricing around $70 to $120 seems reasonable based on the existing modular tool market. Heavy-duty construction costs more to manufacture, and Roxon’s targeting professional users who’ll pay for durability rather than casual buyers shopping on price alone. The Flex Titan launches later this month, with full specifications and pricing available at that time.