REVIEW – As my exploits with sublimation and goods customization have expanded, I jumped at the opportunity to review the AKEYDIY 3-in-1 Auto Hat Heat Press. Let’s find out if it’s a worthy addition to your crafting and maker space!

⬇︎ Jump to summary (pros/cons)

Price: $165.99 on Amazon and $139.99 ok AKEYDIY

Where to buy: Amazon and AKEYDIY

Warning: designing hats is harder than it looks. My apologies for the aesthetic abominations which lie ahead.

What is it?

This is an auto hat heat press, which means it uses a motor (rather than leverage and human energy) to apply the pressure and heat required for working with a variety of materials, like anything iron-on. The curved shape of the platen and base are designed for the curved face of various types of fabric headwear.

What’s included?

AKEYDIY includes everything you need to get start making a hat.

- The heat press

- Three bases with integrated mats:

- 70 x 170mm

- 80 x 154mm

- 90 x 168mm

- 16A standard grounded power cord

- Heat-resistant polyester knit gloves

- 5mm polyamide (Kapton) tape roll

- White polyester double snapback trucker hat

- Pack of five assorted DTF stickers

Included accessories

The DTF stickers gave me a chance to try using DTF for myself, but the designs leave a lot to be desired. It’s an easy way to get started using the hardware though, so I appreciate AKEYDIY including the pack.

The included hat is a very cheap foam polyester trucker design. I really dislike this particular material, because it retains impressions too easily.

The included gloves are absolutely terrible. Do yourself a favor, and buy a pair of decent heat-resistant gloves, instead. That said, since fabric cools quickly and the platen is tilted reasonably far from the base when the machine is open, I didn’t find gloves necessary for safety – and I am hilariously klutzy.

I don’t like the quality of the accessories AKEYDIY included with this heat press. I’d rather nothing be included than low-quality product which is just going to end up in the garbage.

Design and features

The AKEYDIY hat press uses different base plates to make it easier to press different hat sizes and shapes. The medium (80mm) plate is a flatter curve than the small (70mm) and large (90mm) options.

The plates install into two large holes atop the heat press. It’s unclear whether these plates are available as a separate purchase.

The heating element is inside the teflon-coated platen, which is attached to a hinged arm. There is a mechanism inside this arm’s plastic shell which tightens to apply pressure when activated.

This type of auto hat press generally features a lever mechanism for applying tension to a blank hat, which stretches and straightens the material for pressing.

The backlit control panel is all touch. The power button is illuminated red when the machine is plugged in and powered off. Pressing and holding this button toggles the power state of the machine; pressing it momentarily (after powering on) will activate or deactivate the auto press. The temperature and time buttons allow adjusting these two parameters. Conspicuously missing is a means of adjusting the pressure. This is annoying. This additional adjustment would make it easier to dial in the right settings for optimal results, no matter the substrate or applique. The large, segmented display above the control panel displays the time or temperature while setting these parameters and otherwise shows the realtime temperature during preheating.

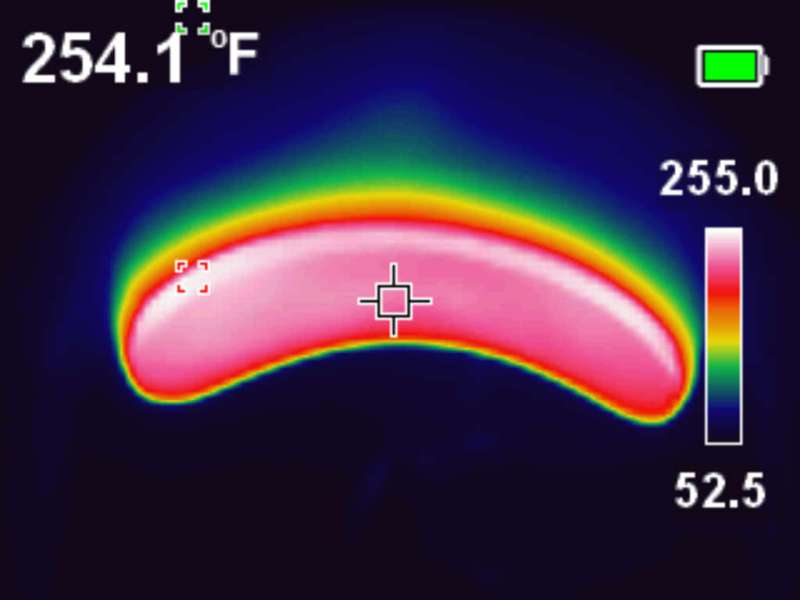

On my machine, the platen temperature appears to be quite a bit cooler than indicated on the display. This is easy enough to accommodate, but I do wish it was more accurate.

Comparing to other hat heat presses

Although I haven’t evaluated or owned other hat presses, I did a little research on currently available hardware.

Consumer hardware for producing hats falls into three categories:

Hand presses: These presses are hand-operated, meaning you apply pressure through your own physical exertion. They generally include some sort of form or stand to support a hat for pressing. The press itself has a concave platen, making it suitable for many hats. Hand presses are inexpensive, compact, and portable – but they’re also more tiring to use if you plan on making a lot of hats, and obtaining consistent results can be more of a challenge.

Manual presses: A manual press is workbench equipment. Like a regular heat press, these rely on leverage and human energy to apply pressure. The pressure is usually adjustable with a knob. Due to the lever design, manual hat presses have a sizeable vertical footprint. Very frequent use (making a dozen hats, for example), can lead to pain from repetitive motion injuries.

Auto presses: These benchtop presses use an electric motor to apply pressure, making operation as simple as pressing a button. Some auto presses include a knob for manual pressure adjustment, but most consumer options do not offer any means of accomplishing this.

So which is right for you? Any type of heat transfer material (HTV, iron-on patches, etc.) generally only requires fifteen seconds to adhere, which means using a hand press might not be too difficult or tiresome for you. Sublimation takes quite a bit longer (at least a full minute), making the use of a real hat press much more appealing.

Consider what you want to produce, how often you want to customize headwear, and where your press is going to live. If you want to produce other goods which require a heat press, do some research on various benchtop presses which are flexible and can switch between hat and flat platens.

What can you make with this heat press?

A wide variety of products are designed to be applied with a normal household clothes iron. Any of these products are compatible with the AKEYDIY hat press, including (but not limited to):

Patches! I used my laser engraver to customize some inexpensive pleather patches with an iron-on adhesive backing. The heat from the press toasted the fish patch a bit, but the final effect is really nice with the vintage cotton fabric of the baseball cap.

Vinyl! If you own a Cricut or other craft plotter, you can use HTV of your choice to make all sorts of custom headwear. The fish hat in the below photo is made with a glow HTV; the rabbit is sublimated on glitter sublimation HTV.

Sublimation! You can sublimate designs directly onto polyester, neoprene, and nylon. This requires a white hat, although I did experiment with sublimating on some color block polyester trucker hats.

DTF stickers! Direct-to-film (DTF) printing is a method of printing an image in reverse on disposable transparent film. A powder adhesive is applied to the printed image, which cures into a solid layer. The resulting sticker is applied to a hat using the aforementioned film to hold it in place. One the sticker is set, the film is removed and discarded.

Because it’s not possible to adjust the pressure, I’m not sure how well iron-on rhinestone materials will work. Additional padding might be necessary between the press platen and the surface of the iron-on material.

I found this press tends to leave an impression on hats regardless of hat material. I used a small teflon pillow from a set I purchased on Amazon awhile ago, and it worked to minimize, but not eliminate, the impression left by press. You can try steaming 100% cotton hats, but polyester might be a bit of a challenge to shape once pressed.

What I like about the AKEYDIY 3-in-1 Auto Hat Heat Press

- Easy to operate

- Small footprint

- Easy to move and store

What needs to be improved?

- Adjustable pressure

- Temperature isn’t calibrated

Final thoughts

Of all the sublimation and heat press devices I’ve used, I have to admit, I’m the least enthusiastic about this hat press. It’s a bit of a challenge to come up with good hat designs – what looks good on screen doesn’t always look very good on a person’s head!

That said, this press works fine for applying all manner of iron-on embellishments to your favorite styles of headwear. I haven’t used other hat presses, so I can’t compare it to other options, but the hardware itself is pretty standard as these products go.

With an MSRP of $160 (currently $140 on Amazon), this is what I’d consider an entry level heat press. I don’t expect a particularly long lifespan out of any of the components which will experience the most wear (the heating element, motor, and tension springs). The lack of adjustable pressure is a big miss, and I’m inclined to recommend a manual press over this model.

Since there’s no obvious way to purchase replacement base plates and mats, it’s a good idea to use a replaceable silicone mat to maximize the longevity of the base plates.

If you make a lot of custom hats, a benchtop press is a worthy investment, but I think it’s probably wise to choose higher quality brand and machine.

If you don’t produce hats often enough to need the features of a benchtop press, a handheld press is more than adequate for applying iron-on embellishments of all kinds. Sublimation is where high heat and steady, strong pressure matter most, and hats just aren’t a good product for sublimation.

Price: $165.99 on Amazon and $139.99 ok AKEYDIY

Where to buy: Amazon and AKEYDIY

Source: The sample for this review was provided by AKEYDIY. AKEYDIY did not have a final say on the review and did not preview the review before it was published.