REVIEW – I remember reading a Time magazine article in the 1980s about computer numerical control (CNC) manufacturing. I never thought decades later, I’d be able to have that kind of power at home in a DIY kit from Monoprice, of all places. I also never thought I’d burn three days trying to figure out how this all works.

What is it?

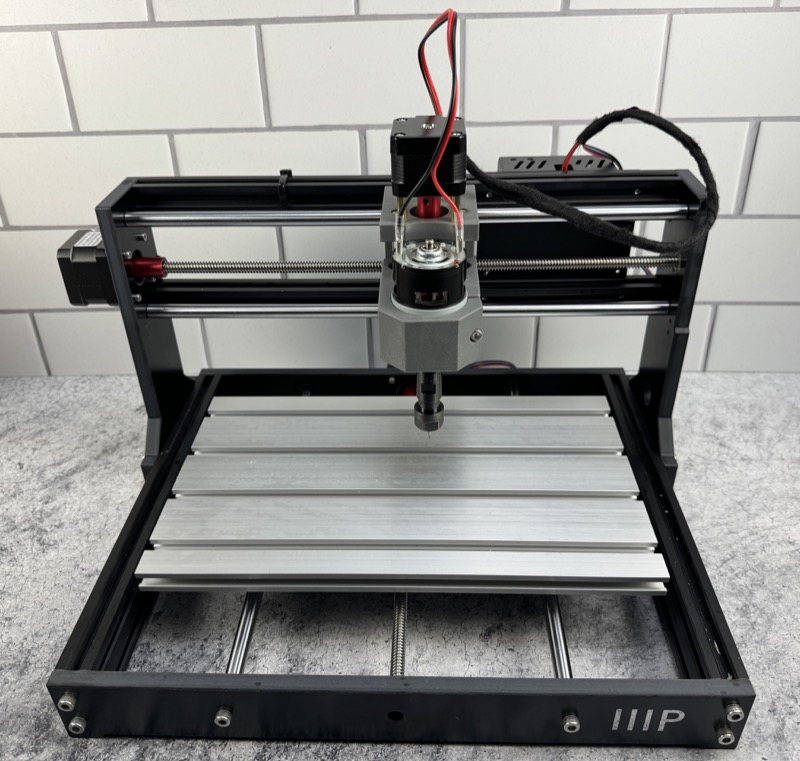

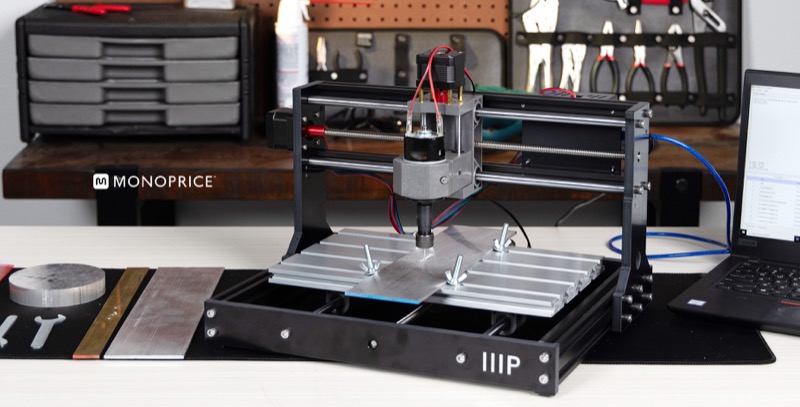

The Monoprice CNC router kit (part# 44220) is a compact, USB programmable, 3 axis engraver and miller. It appears to follow the same specs and dimensions of a class of CNC routers known as “3018” style, named after the size of the workspace (300 x 180 mm).

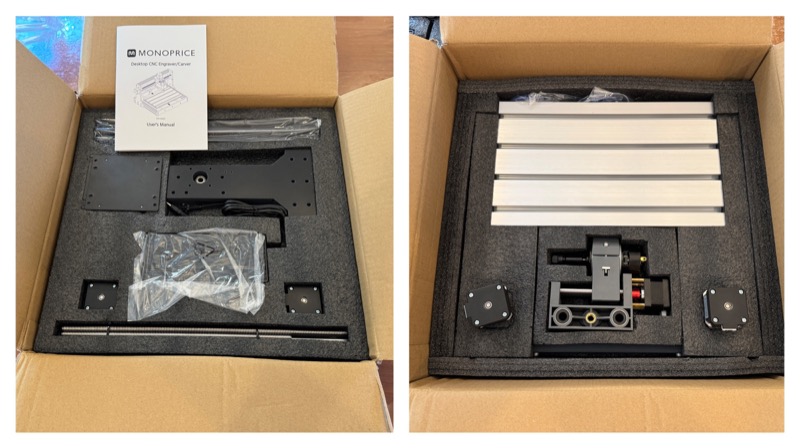

What’s in the box?

- All the parts of the Monoprice 44220

- 24DC power supply

- USB cable

Hardware specs

- P/N 44220

- Supported Software Candle or other GRBL software

- Supported Carving Materials Soft metals and materials (e.g. copper, brass, aluminum, plastic, wood, acrylic, PVC, PCB, and similar)

- Engraving Area 11.8″ x 7.1″ x 1.6″ (300 x 180 x 40 mm)

- Input Power 24 VDC, 4A

- AC Adapter Input Power 100 ~ 240 VAC, 50/60 Hz

- Spindle Motor Speeds 7000 rpm or 9000 rpm

- Stepper Motor Torque 1.3A 0.25Nm

- Supported Operating Systems Windows® XP, 7, 8, 10 Home Version

- Drill Bits 3.175mm diameter, 0.1mm tip, 30mm length

- Dimensions 16.5″ x 10.0″ x 11.0″ (420 x 255 x 280 mm)

- Packaging Method Corrugated Box

- Dimensions (LxWxH) 17.9″ x 16.1″ x 6.4″ (455 x 409 x 163 mm)

- Weight 17 lbs. (7.7 kg)

Setup

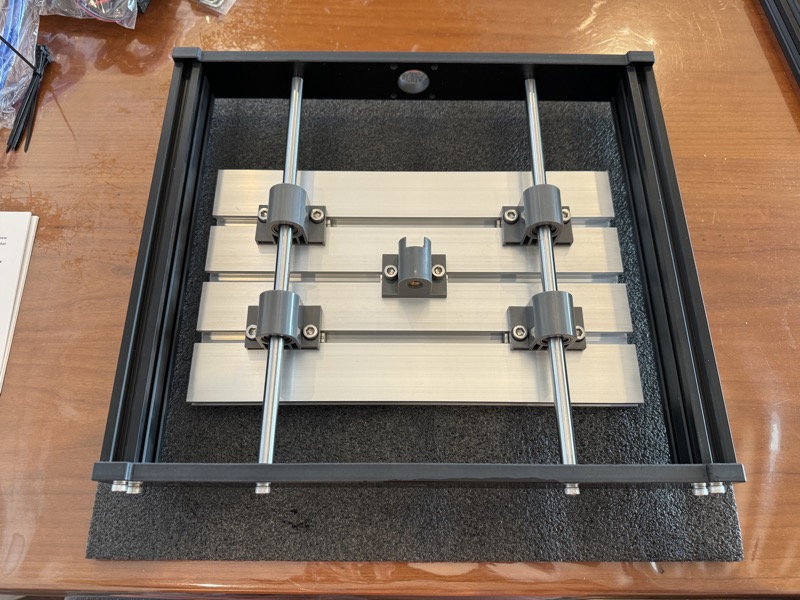

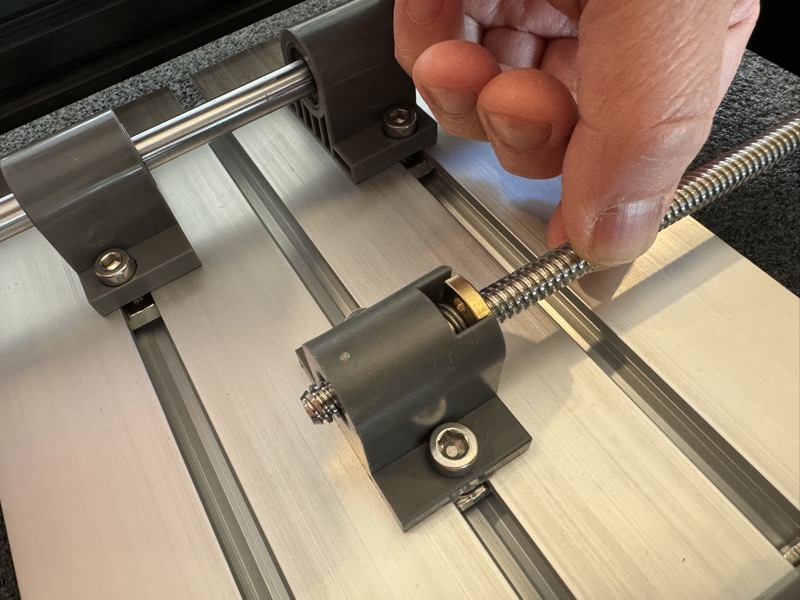

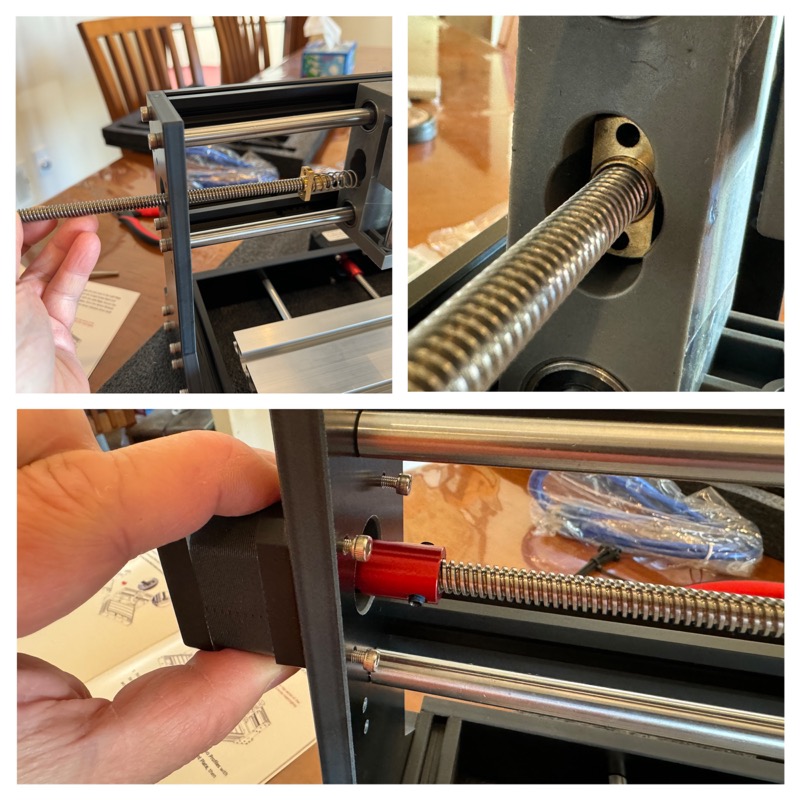

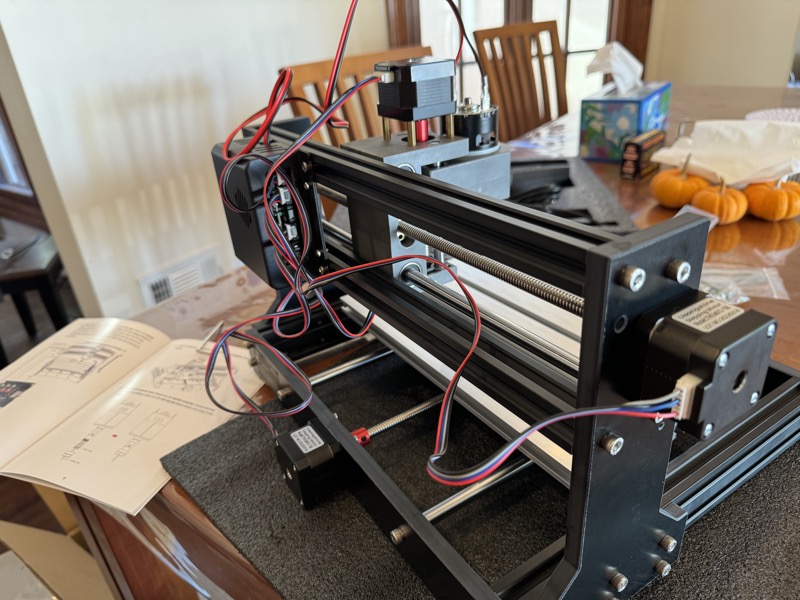

The largest item in the box is the sliding work surface. A threaded rod moves the surface.

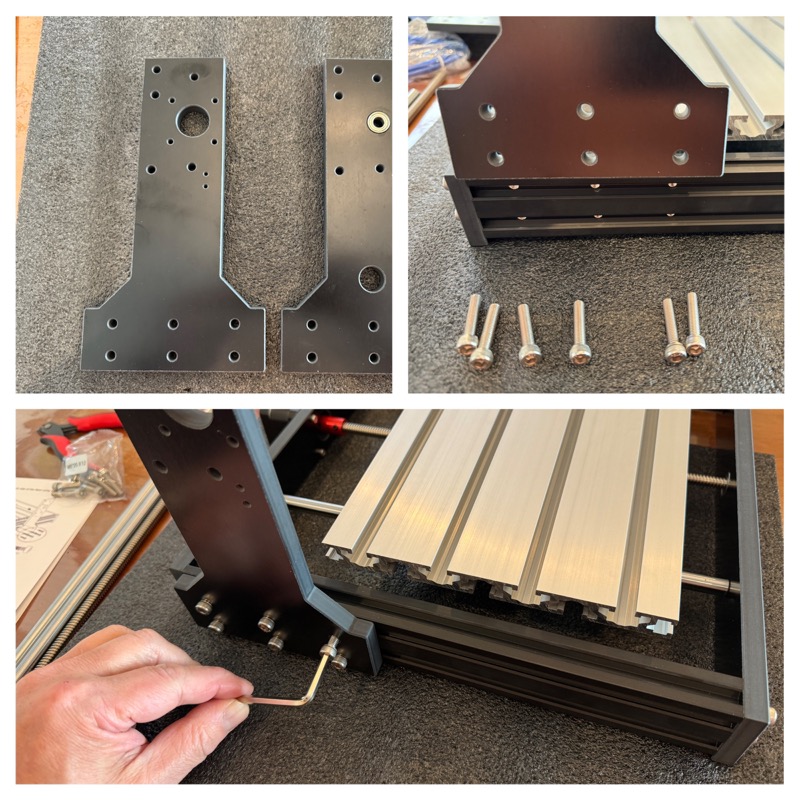

Six bolts secure the vertical risers on each side.

Another threaded rod slides the cutting head left and right.

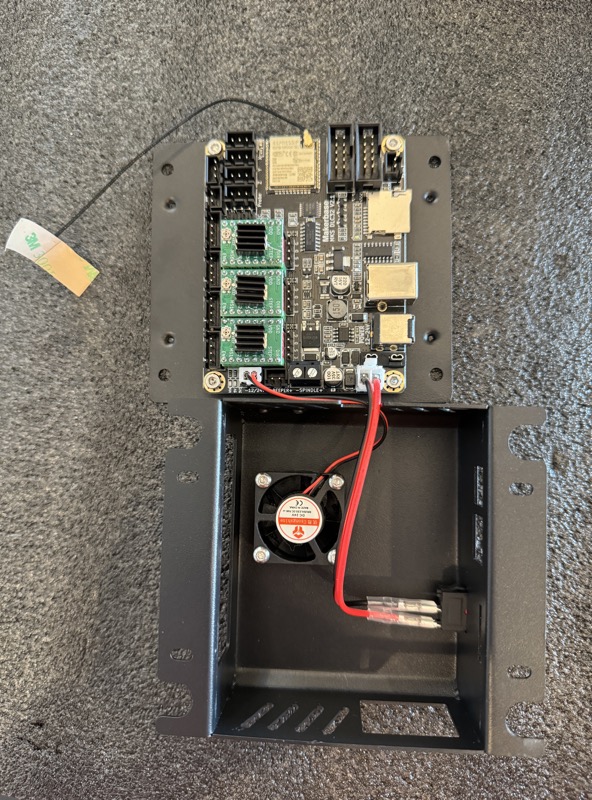

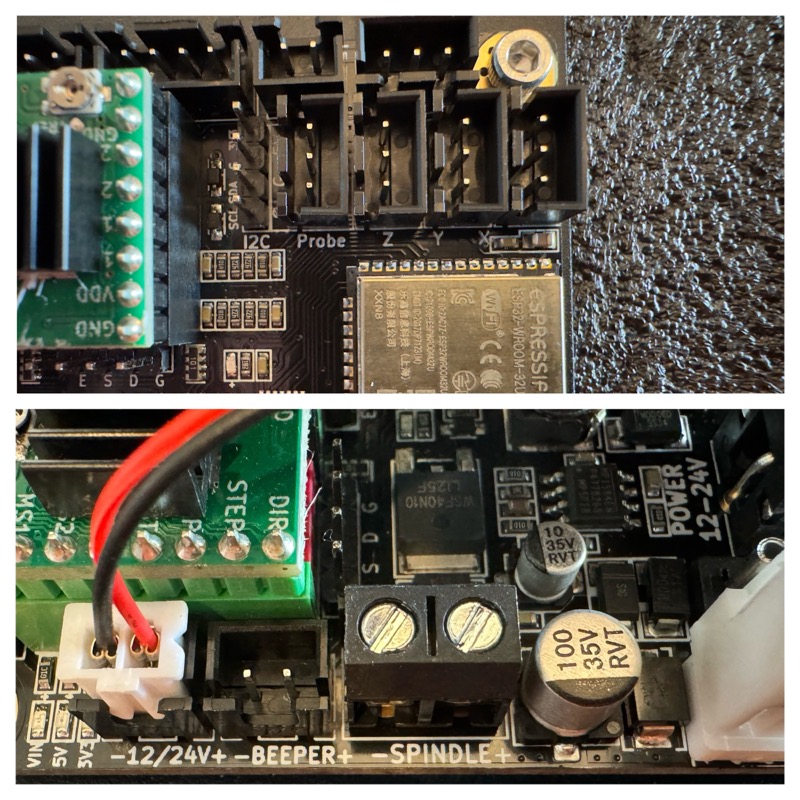

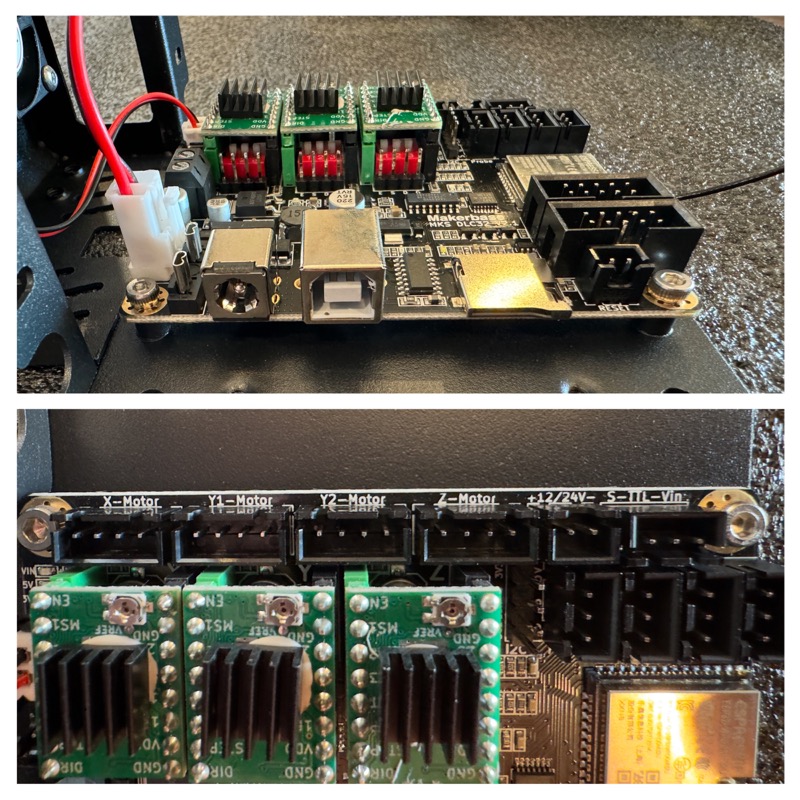

The controller is labeled as a Makerbase DLC32 V2.1. The power switch and cooling fan are preinstalled.

There are many ports on the board. Not all of them are used, such as the Z probe and limit switches.

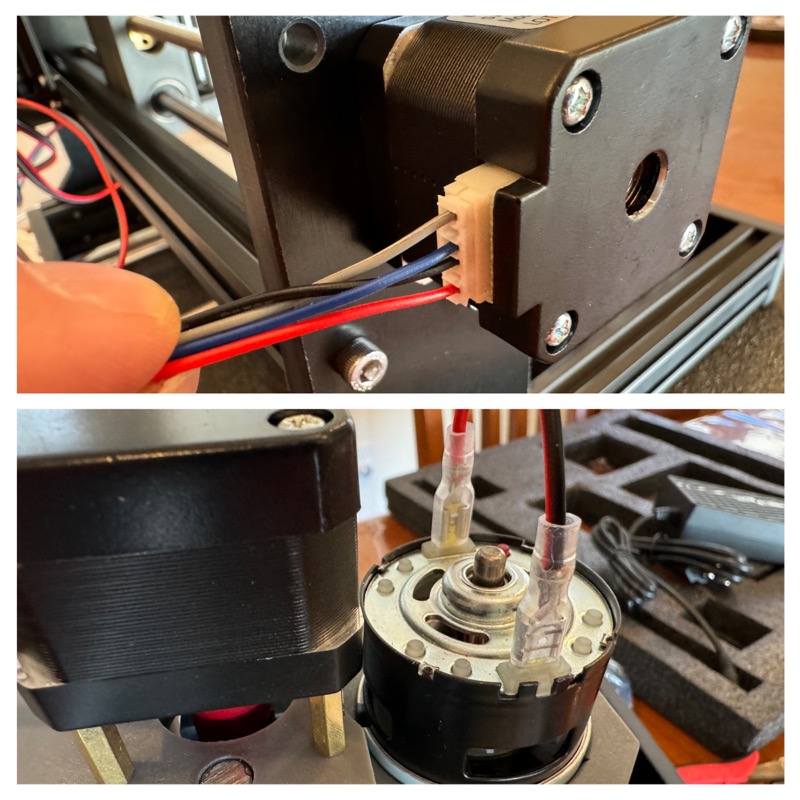

Three cable bundles go to the three stepper motors: One for X, Y and Z. The cutting motor itself connects to the Spindle header on the board.

The rear of the 44220 with the cables attached. I eventually tidied it up a bit but careful not to interfere with the X, Y and Z range of motion.

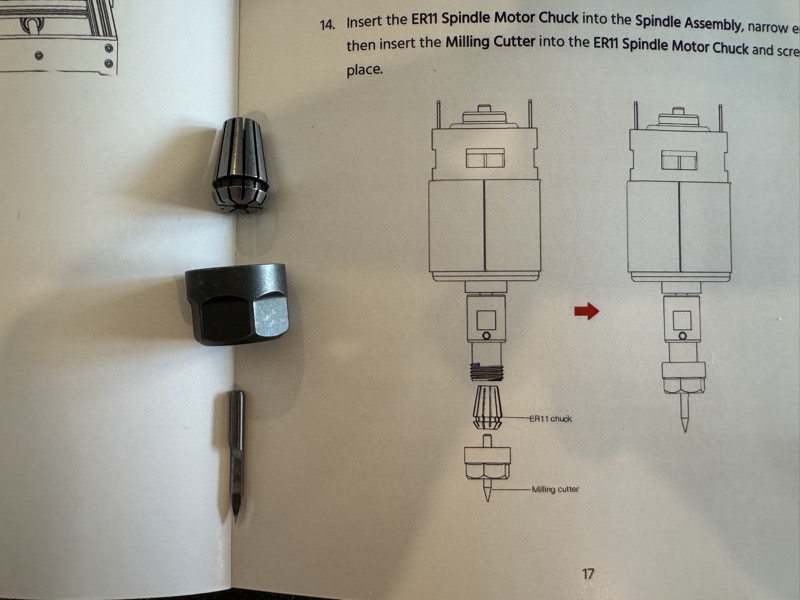

The kit comes with 10 pointy cutting tools, which fit into the ER11 chuck.

I discovered that assembling the 44220 wasn’t too difficult. What was excessively hard was climbing the steep learning curve involved in bringing such a tool to life.

The world of hobbyist CNC is boundless and full of potential, but be prepared to spend some time figuring out how to get started. I have zero experience in this area, but over three days, I managed to assemble the 44220 and carve out a simple project.

There may be slicker ways to go about this, but there are three basic steps to creating a CNC project:

- Come up with a design in a usable format, such as SVG

- Convert the SVG into machine routing instructions

- Send the routing instructions to the CNC machine itself for actual cutting

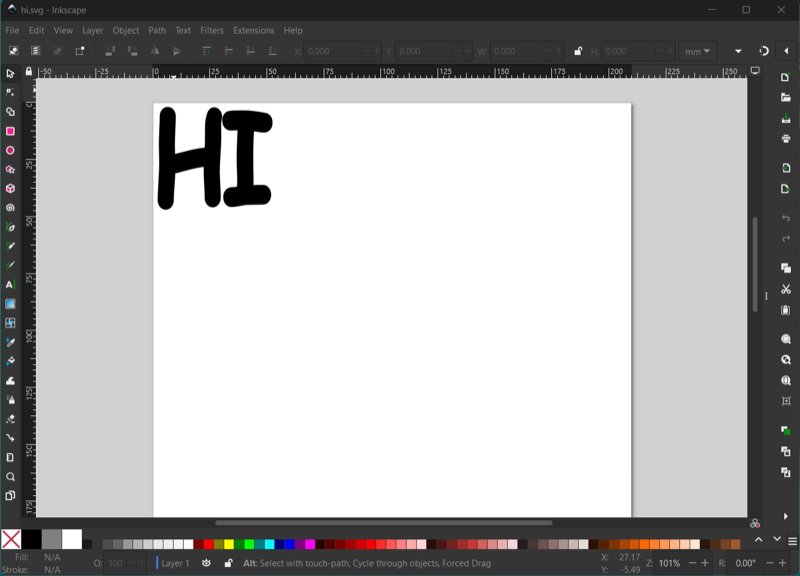

I use a program called Inkscape to create an SVG file. In this case, the word “HI” in Comic Sans- which seems to be tailor made for CNC. I invoked the “object to path” command and saved the file.

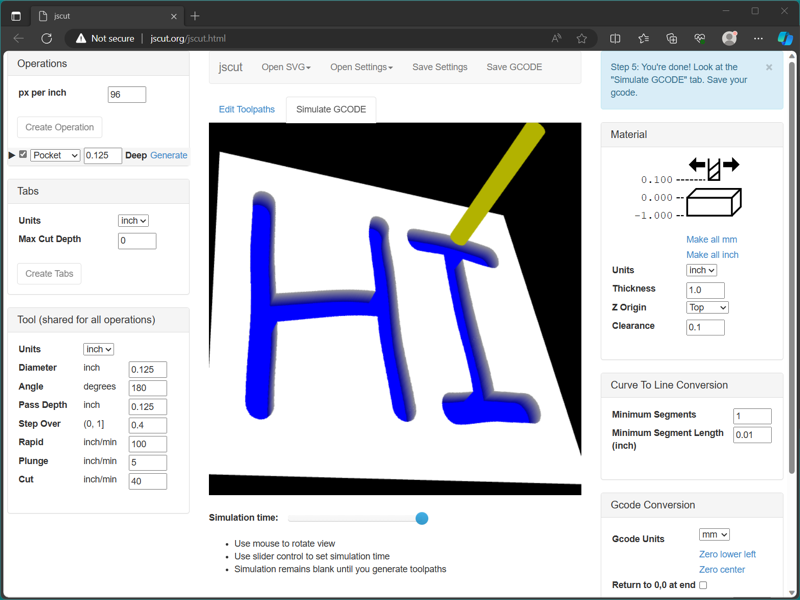

Next, I had to take that SVG and create turn-by-turn instructions that a CNC can read. For this, I turned to jscut, a brower-based tool. Here you can see a simulated preview. Saving the GCODE saves a text file you can edit. For example, I learned jscut doesn’t automatically add code to turn the spindle motor on and off. It can be added in manually in a text editor if you wish.

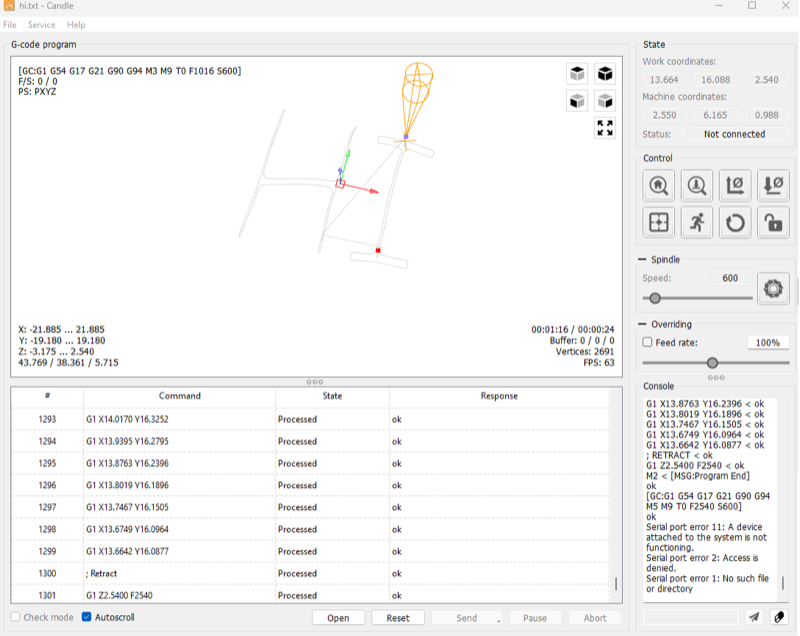

Now that I had the “instructions” in a text file, I used a program called Candle which can take these instructions and send them to the CNC. I also fiddled around with Universal G-code Sender (UGS) as well. Both are free.

Performance

This isn’t anything fancy, but that’s on purpose. Here’s a short clip of the CNC in action.

You’ll notice the big clamp holding down the board. I borrowed that from my drill press. The bolt and wingnuts that came with the 44220 aren’t very helpful.

As you can see, there are still bits of wood in the center of the letter strokes. Oops! Clearly, there’s some fine-tuning required!

What I like

- Not hard to build

- All the wrenches are included

- Affordable

What I’d change

- There is a long and steep learning curve

Final thoughts

I can see how in the right hands, the Monoprice 44220 “3018-style” CNC router is an affordable, powerful DIY tool. There are no printed instructions on getting this set up for your first project. I had to figure out everything from extensive Google-Fu and watching YouTube videos. Even then, simple tasks such as calibration and interpreting the user interfaces of Candle and UGS actually hurt my self-esteem and I consider myself fairly handy.

Bear in mind that all the software I used are free. There may be other software packages that make life easier, but that’s not the scope of my review. If you’re already familiar with 3018 CNC machines, I’ll bet the 44220 looks familiar to the dozens of lookalikes available out there.

Price: $189.99

Where to buy: Monoprice and Amazon

Source: The sample of this product was provided by Monoprice.