REVIEW – This may surprise you (or not), but the Gadgeteers have a gadget Discord where we chat about all kinds of things. It’s kind of a geekfest, as you might imagine, but if you are a geek like me, you kinda love it. The coolest of the geek discussions by far is the laser cutter/engraving discord. People post up the coolest stuff that they’ve made. I have the “hobbyist” version of one of these, the Cricut, but I was looking for a way to go more hard core — and then the Swiitol folks launched the Swiitol C18 Pro 18W laser engraving machine. I wasted no time in getting it up and running.

What is it?

The Swiitol C18 Pro is a high accuracy 18W laser cutter/engraver.

What’s included?

- The parts to make the laser cutter/engraver (there were a lot)

- The tools to make the laser cutter/engraver

- A USB cable

- A few spare parts that will figure prominently in the review

- Some “blanks” for testing (small pieces of metal and wood)

- An instruction book/manual

Tech specifications

Engraving ruler: 400mm x 4000mm

Electric power: 90W

Laser output optical power: 15-18W

Laser wave: 455 +/- 5nm

Engraving accuracy: .01mm

Net weight: 4.6kg

Data transmission type: USB connection

Focusing Type: Fixed focus laser, no focusing

Operating software: LaserGRBL, LightBurn, with WinXP/Win 7/Win 8/Win 10

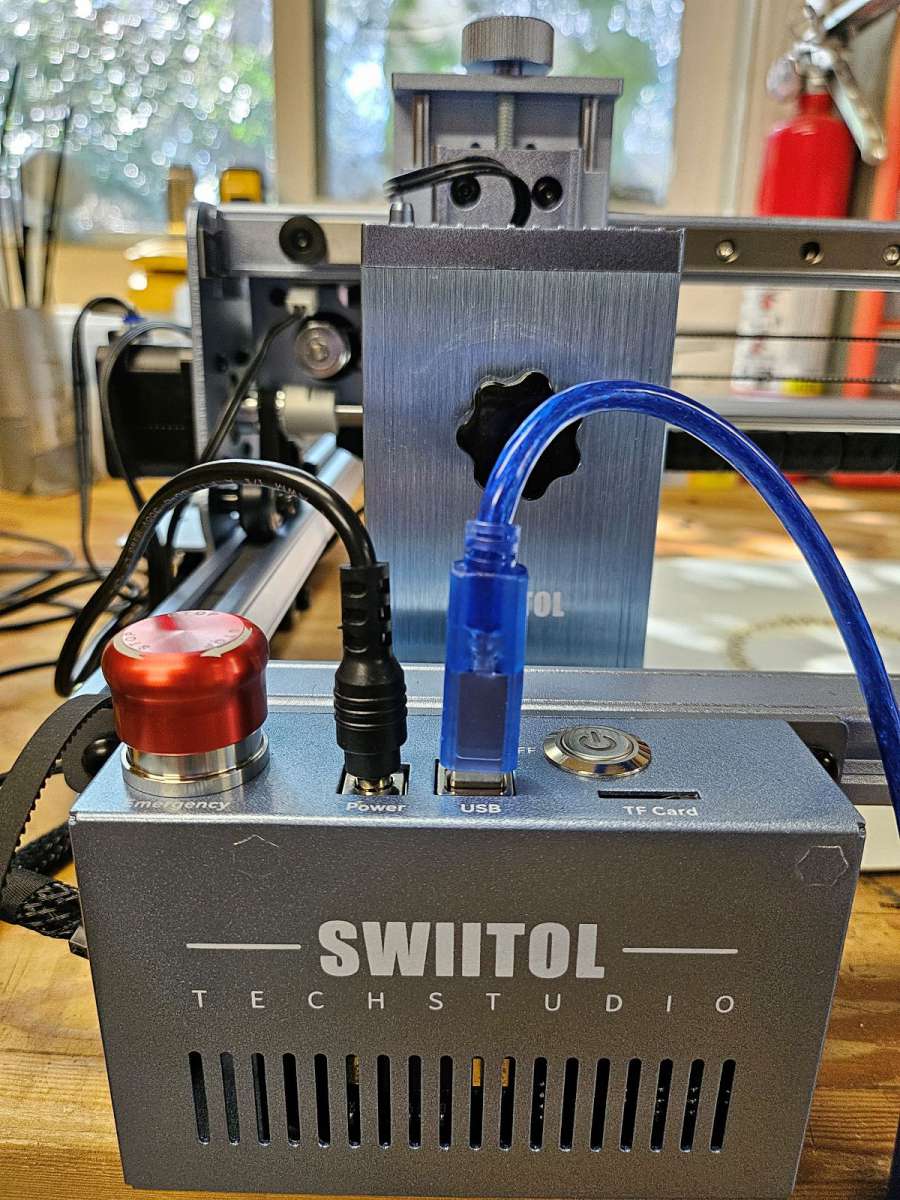

Design and features

The Swiitol C18 Pro 18W laser engraving machine is a laser cutter/engraver that features a .08x.08 laser spot that is supposed to work much faster than other products on the market. It includes a pre-installed air-assist and a light filter that should filter 97% of harmful light. There are multiple security features including a flame alarm, a stop button, a safety lock and slope protection. There is also an app for designing projects and accessing a material library called Burnlab that is compatible with this machine. I should note that I was pretty confused about what model I was reviewing because the website for this product shows extendable legs, and there are not extendable legs on this machine.

Assembly

My son was so excited that we were getting the Swiitol C18 Pro laser engraver that he couldn’t wait to open the box. Unfortunately, he opened it upside down, so any cool pictures I was going to take of the packaging were out of the question. What I can say is this: everything arrived and worked, so my best guess is that they were all packed very well until my son got busy with the box cutter.

The instructions were fairly straightforward. Did I have to take it all apart once because one of the critical pieces was upside down? Yes. Was it hard? No. I did manage to lose a screw and a screw and metal piece that locks down the gear belt. I went crazy trying to find the screw with the metal piece, because it seemed pretty important to the functioning of the machine, and even though I swept the area with a magnet and got out a flashlight to search…it didn’t turn up until I carried the Swiitol C18 Pro to the workshop for testing. Then it rattled out of some crevice in the machine. By that time, however, I had MacGuyvered something that seemed to work, so I just kept those pieces handy in case and I’m glad I did.

The Swiitol C18 Pro laser engraver comes with a couple of spare parts, but for the life of me I don’t know where those spares are supposed to go. That brings me to my first recommendation: if you’re going to include spare parts, make them useful. The items in the spare parts don’t fit anywhere I can figure out.

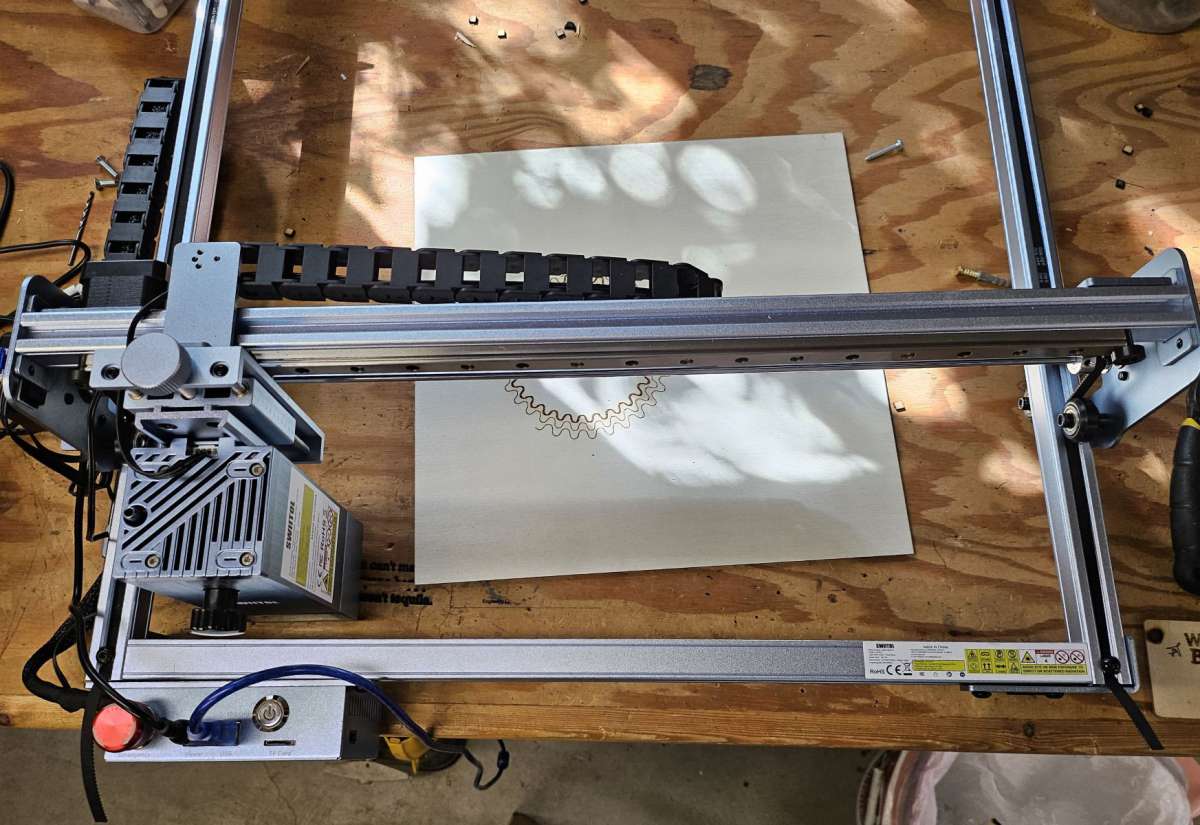

After the Swiitol C18 Pro laser engraver was built I installed LaserGRBL and Inkscape, watched some videos about how both of those pieces of software worked, and then I got down to burning some stuff!

Performance

I’d like to kick off this section with the disclaimer that I am a complete engraving/cutting novice. I have never used Inkscape, LaserGRBL or a laser engraver before. I really had no idea what to expect. Thankfully Youtube showed me a few tips and tricks, and I had ordered plenty of wood from my favorite online retailer and so I had plenty of materials to mess around and an experiment with.

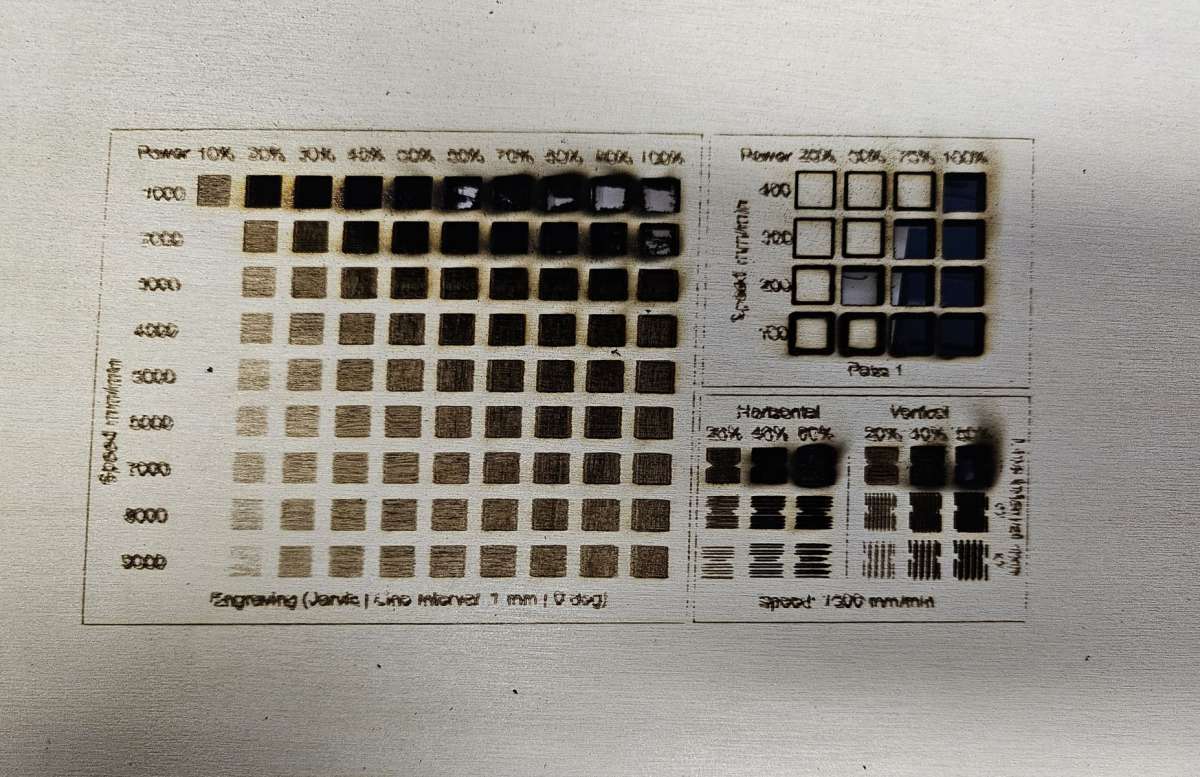

My first goal was to make a luggage tag, because that involves cutting out a rectangle and a hole, and engraving some information. I watched a video on how to do it, but I never really made a great one. I think I might have started with the hardest task. I was able to engrave on wood but I was having trouble finding a great setting for cutting the wood.

That’s when I learned that you should make a test sheet of your laser cutter at different speeds and power so that you can tell how your particular machine works on different materials. I scoured the internet for one and that gave me a pretty good idea of what power would cut the kind of wood I was using. I made three “tags” and all with their strengths and weaknesses. I really liked the way the Swiitol C18 Pro laser engraver made such precise engravings! On the flip side, I do not like how hard it is to center things and make sure they are level/even. Perhaps this is a problem common to all laser engravers, I don’t know. In LaserGRBL you can see an outline of the items you are about to engrave or cut, but you really can’t see your graphic before it starts so you know how well it lines up with the edges of your material. I found it very frustrating and time consuming.

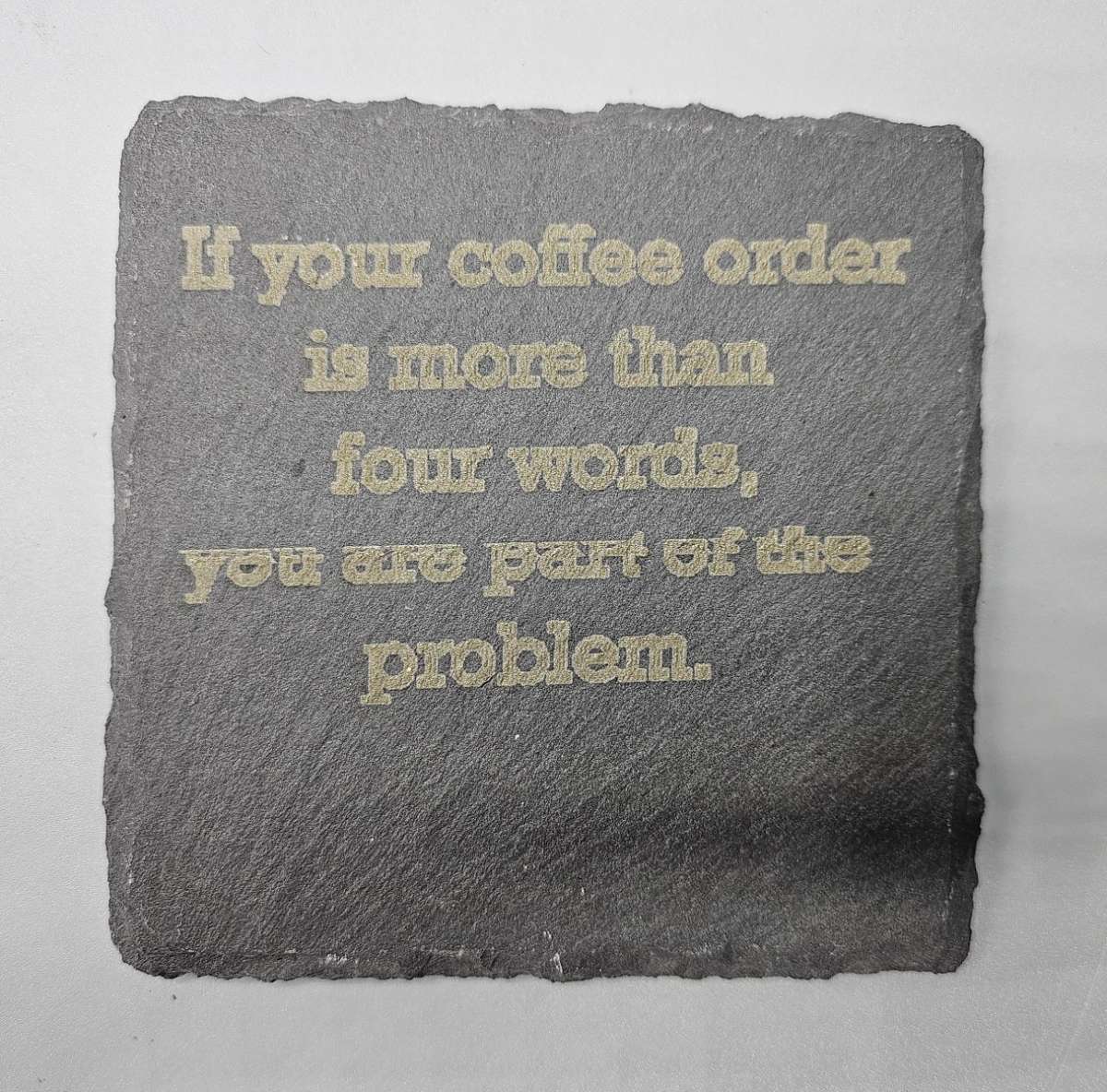

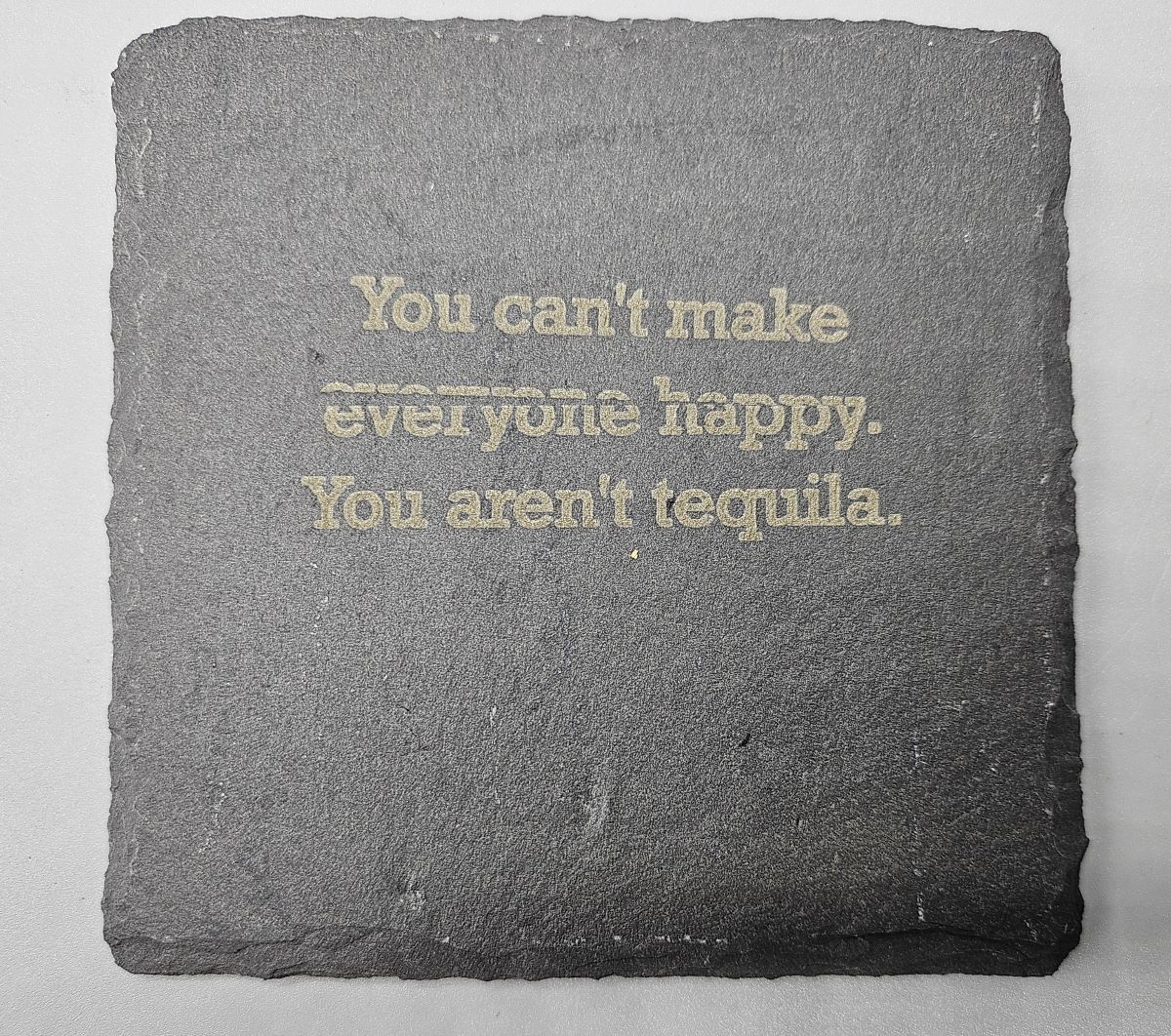

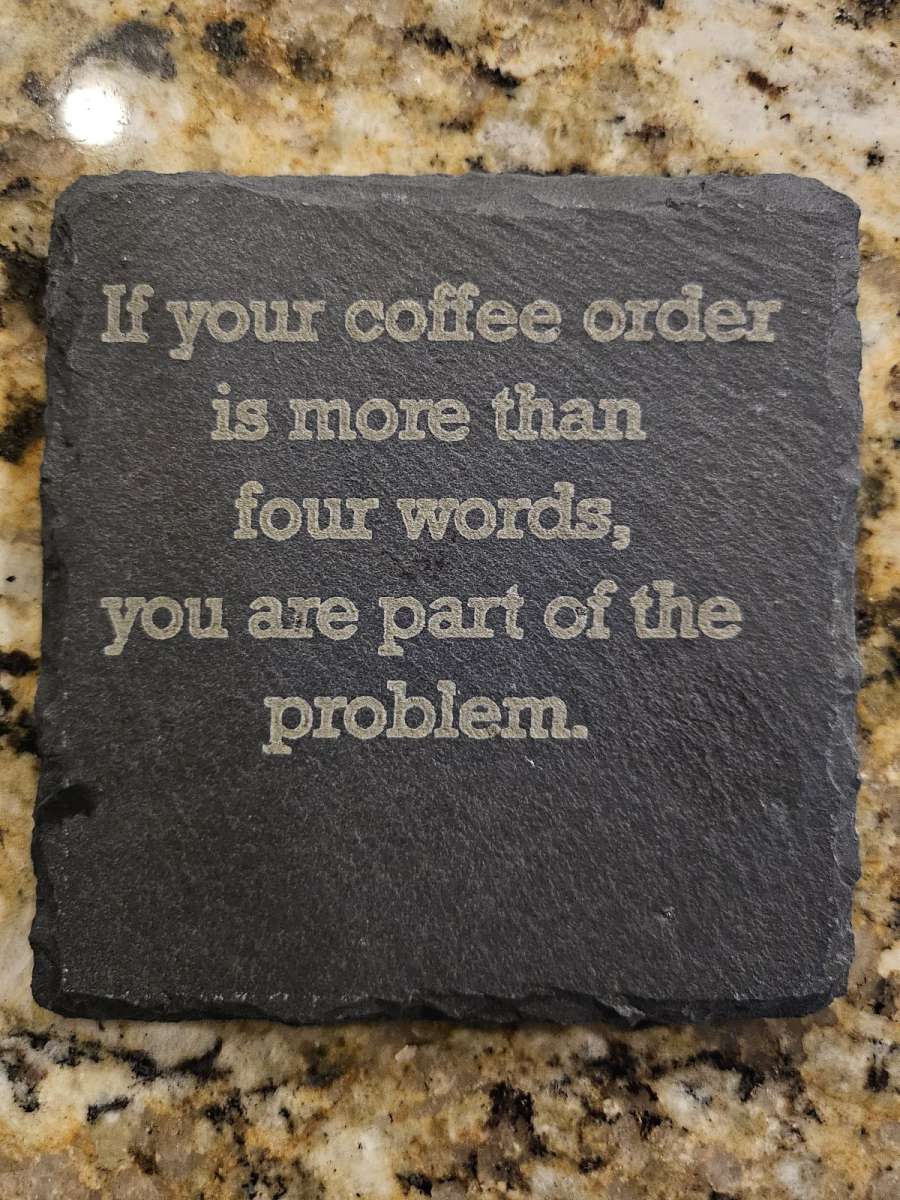

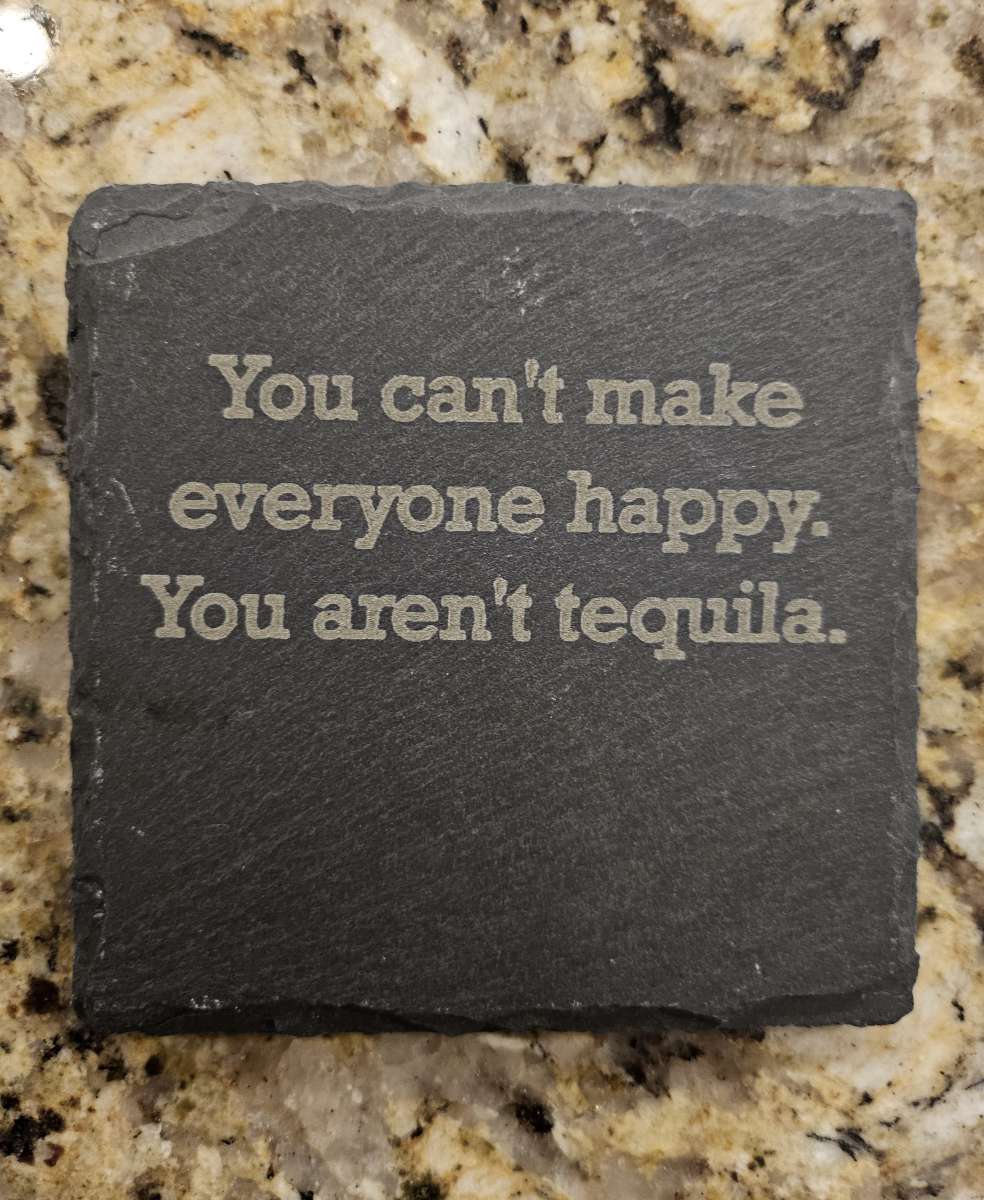

I moved on to make some coasters. I bought some slate coasters that I wanted to engrave, so once again, I did a test pattern burn on slate to pick some good settings. Then I created my designs (which are just some sassy quotes from a calendar I have) in Inkscape and then imported them into LaserGRBL. After painstakingly trying to center the text, I engraved the costers with the Swiitol C18 Pro laser engraver. The beauty of slate, I think, is that it doesn’t scorch! I liked the way these turned out a lot, but it wasn’t the easiest project because my computer would disconnect from the C18 Pro for seemingly no reason. Once I reconnected to the C18 Pro, the program asked me if I’d like to resume at the last line of instruction, and even though that should mean a seamless start, it messed up the engraving. Even if I sat and babysat the project for the full engraving time (which you should do anyway since you’re dealing with lasers that can catch things on fire), I still wound up with some coasters that had problems. Is this the fault of the C18 Pro, or is it my computer? I don’t know. But it wasn’t the easy project I’d hoped it would be.

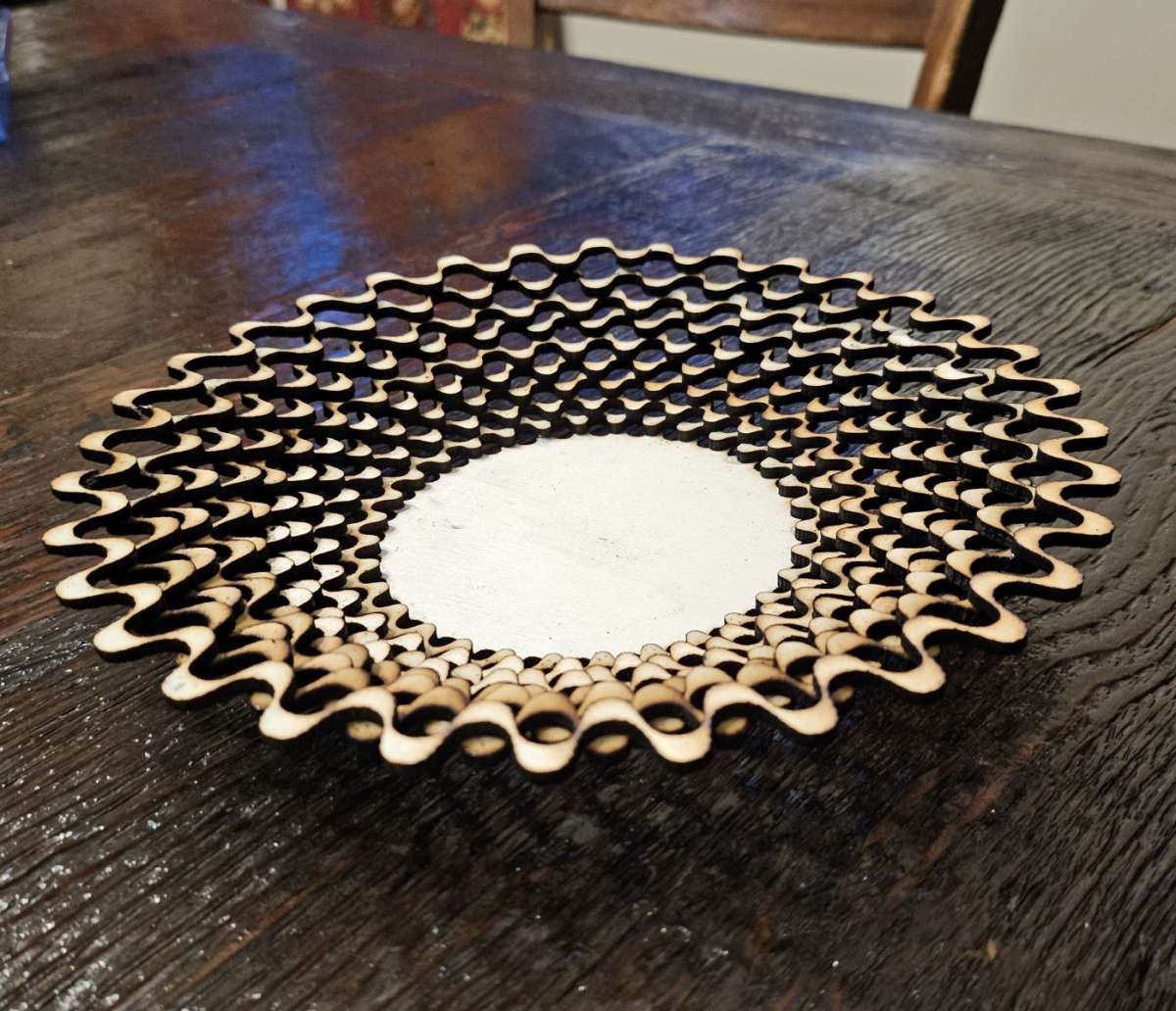

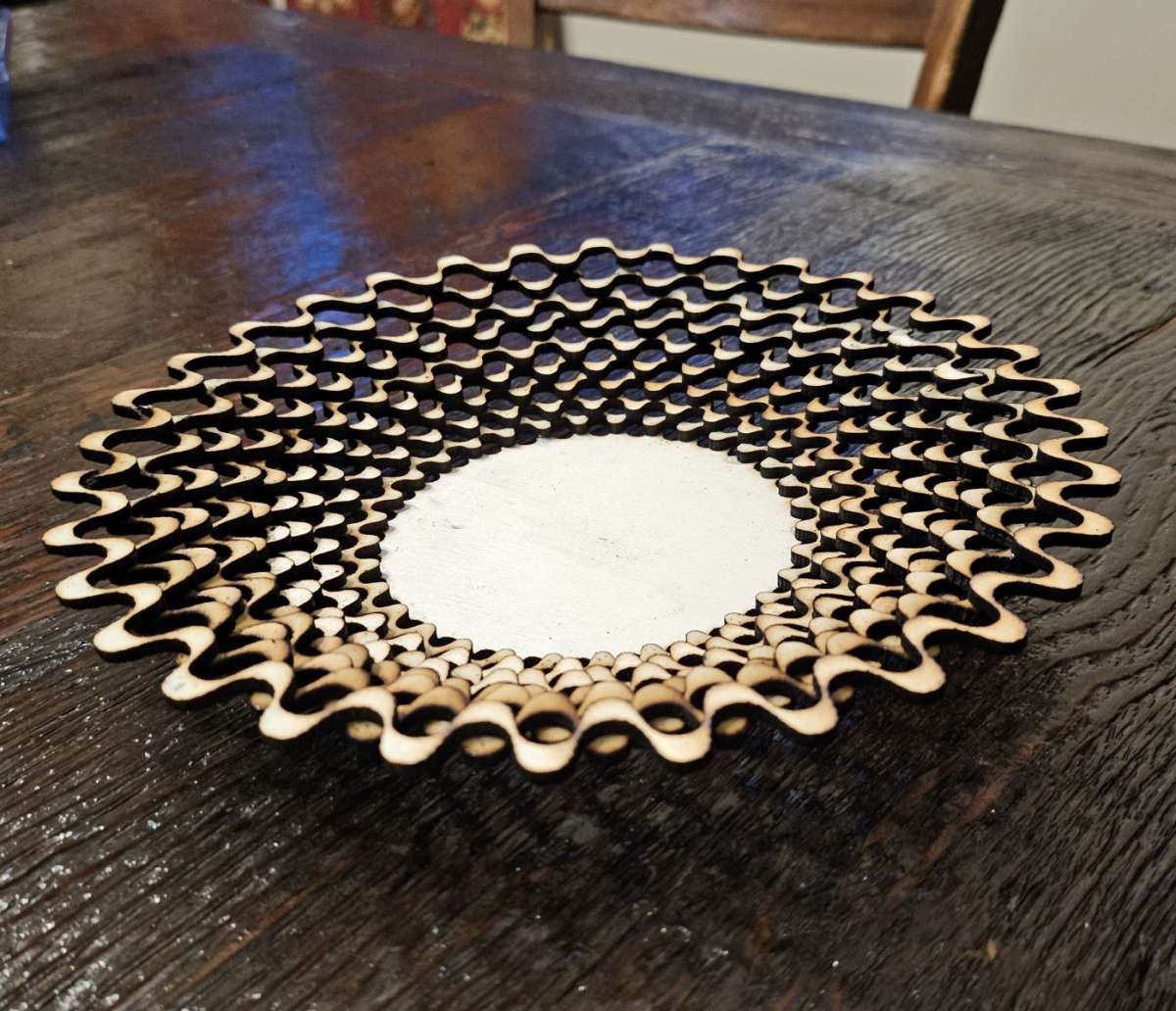

Finally, I decided to try and do something more complicated in design, so I downloaded a pattern for a wood bowl and picked a setting for cutting wood. This wood bowl turned out great, but half of it was more “scorchy” than the other side. I posted this on my social media and one of my friends from high school who is an experienced laser cutter said it looked like one of the belts was loose. He was right! It was from the side of the Swiitol C18 Pro laser engraver that I had to “rig up” because the screw and clamp that were supposed to be there were lost. The bowl still turned out pretty nice, but it brought home the fact that you really have to be careful when you assemble these kinds of machines. If anything is out of whack, it shows in the finished piece.

I attempted some more coasters after I tightened the belts and ran into some of the problems I described above with the connecting and disconnecting mid project. In the future I might try using the app to see if things go better, but the app kind of confuses me. The Burnlab app allows you to connect to the machine with your phone, but it’s not made by Swiitol. It is an app that works with several brands of laser cutter engravers. I didn’t use it because I can’t imagine trying to design something on my dinky phone screen. However, if it solves my connection issue, I might try to get used to it.

What I liked about the Swiitol C18 Pro laser engraver

- Precise engravings.

- Built-in air assist

- Safety features

What needs to be improved?

- Connection issues and other issues that affect the final product

- Include useful spare parts

- Don’t show extendable feet on the website if there are no extendable feet on the product.

Final thoughts

I wasn’t wowed by the performance of the Swiitol C18 Pro laser engraver, quite frankly. I don’t know if the problems I ran into that affected the final products are typical or an issue with my computer, but my computer is fairly new and I couldn’t figure out a reason why the connection was dropped. All I know is that I wasted some blanks because this machine didn’t always behave as expected, and that’s disappointing.

Price: $321.99 with an $8.00 coupon on the Swiitol site

Where to buy: Swiitol and Amazon

Source: The sample of this product was provided for free by Swiitol. Swiitol did not have a final say on the review and did not preview the review before it was published.

![[Strong Magnetic Lock]:Built-in magnets, offering a magnetic force of up to 3000g. Ensures the magnetic wallet fits tightly and attaches securely to the back of your iPhone. [Smart Card Storage]:The magnetic wallet is designed ingeniously to hold 5 c...](https://m.media-amazon.com/images/I/41SFnxrNs0L._SL160_.jpg)

Gadgeteer Comment Policy - Please read before commenting

Have any idea what the hdmi port is for?

Have any idea what the hdmi port is for?

I don’t know. The instructions didn’t seem to cover that.

My SWIITOL c18 pro was retired a few days ago. I seem to have a problem with their support and can not get an answer as to why my laser lost power and would not cut anything unless it had full power and speed set to 50 or less. I replaced it with a Longer Ray5 20 watt. It is a much more cooperating machine.

That is good to know. I didn’t know if some of the issues I had were because I was inexperienced or because of the laser or ? After some conversations with others, I think my computer losing connectivity could have been because of Lasergrbl. Over the holidays I might try and figure out a few more things and experiment a bit more.

Something else to not like is the lack of specs and details on use for greenies.

Bought one of these last summer but only got to use it once. Now the power is constant on if it’s plugged in but the device won’t finish powering up.

Have you reached out to their customer support? I’d be interested in knowing how it is. I haven’t used mine in a while.