I love technological advances of all kinds and I loathe illness-causing bacteria. So when Professor Dennis Hess, Associate Professor Julie Champion, Postdoctoral Fellow Yeongseon Jang, and Postdoctoral Fellow Won Tae Choi at Georgia Institute of Technology developed a new nanotextured surface for stainless steel that kills common bacteria I was thrilled.

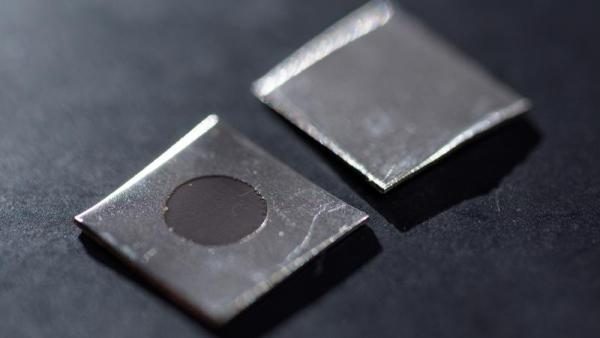

This isn’t a coating that wears away – the stainless steel is physically etched and is thus a permanent treatment. The researchers used an “electrochemical etching process on a common stainless steel alloy” (Georgia Institute of Technology News Center, Curiosity) to create the nanotexture.

The researchers aren’t sure about the mechanism that causes bacterial mortality, but they speculate that the bacteria (which are much smaller than mammalian cells) are physically skewered by the microscopic sharp edges while mammalian cells are left undamaged because of their differences in sizes. So far, they say that the nano-etching has been shown to kill Escherichia coli and Staphylococcus aureus.

This nanotextured stainless steel also seems to improve corrosion resistance and has potential future applications in implantable medical devices and food processing equipment but researchers will be conducting long-term studies to ensure that mammalian cells remain healthy and determine how the etched surface responds to wear over time. Please visit the Georgia Institute of Technology News Center to read more about this promising stainless steel.

Gadgeteer Comment Policy - Please read before commenting

Your headline says that bacteria are killing stainless steel. Now, if you were to hyphenate it as bacteria-killing, you would have an adjective describing a property of the stainless steel, as you intended.

Yes, I first read the headline that way.