REVIEW – I have a small confession: I’m addicted to dye sublimation. I’ve been improving my techniques over time and have made some pretty cool gifts for friends and family. I was stoked when Julie told me about the HTVRONT A200 machine. I was in the market for a drinkware press, so did this cut the mustard? Let’s find out!

⬇︎ Jump to summary (pros/cons)

Price: $279.99

Where to buy: Amazon

Preface: Options for sublimating drinkware

Typically, hobbyists rely on at least one of two options for sublimating drinkware: ovens and heat presses.

A sublimation oven is really just a countertop convection oven. The large capacity of these ovens makes it trivial to produce a reasonable volume of custom drinkware in bulk. This is great if you’re making stuff with specific designs, but it’s less great if you’re more interested in on-demand custom products.

Producing sublimated items with an oven requires the use of shrink wrap, which applies enough pressure to taped-down sublimation paper to result in quality ink transfer. I’ve found shrink wrap emits a gross plastic odor after baking, and it’s a wasteful single use plastic, so not using shrink wrap has its benefits.

A heat press doesn’t require shrink wrap, but it’s also generally not possible to do more than a single item per job, unless you buy a larger press which can handle two 11 oz. coffee mugs simultaneously. Using a heat press is also faster for individual custom items. Metal takes about six minutes to bake; the A200 presses a tumbler in under three and a half minutes.

Six minutes for four tumblers (the capacity of my PYD Life oven; their XL oven can bake eight!) is efficient, but if you’re looking to produce custom items on-demand, a press is certainly less expensive – in time, heat, and consumables – to operate.

What is it?

The HTVRONT A200 is an electronic sublimation heat press. Unlike manual presses, which use leverage and human energy to apply pressure, the A200 uses a motor.

What’s included?

The basic A200 kit includes:

- The main heat press machine

- Straight cylinder insert

- 4mm rubber wrap

- 2mm rubber wrap

- Polyamide tape

- Large heat-resistant gloves

The included gloves are enormous. I previously purchased a pair of similar gloves in a much more manageable size, and I strongly recommend making sure you have a pair of properly-fitting gloves for handling items with this press. Oversized gloves reduce dexterity and increase the likelihood of accidents. You don’t need anything fancy – basic knit gloves with silicone bumps work great!

HTVRONT also offers a specialized insert for large 30-40 oz. tumblers. This insert includes a molded rubber wrap, and the kit also ships with a bright white 40 oz. tumbler with the handle safely wrapped in bubble wrap and stowed in the tumbler.

Design and features

The A200 is a chunky benchtop appliance, with a footprint of about 14″ deep by 24″ wide, including clearance for working with large 40 oz. tumblers. As this device outputs a lot of heat, you won’t want to place it under any cabinets or shelving.

As with the H17 vacuum sublimation machine, HTVRONT’s engineers have gone to considerable effort to find innovative ways of improving on existing heat press technology.

A standard mechanical electric drinkware heat press uses silicone wraps of various sizes, each covered with a thin sheet of wires which serve as the heating element. This heating element, like a flat heat press platen, applies direct heat to the sublimation blank, while the silicone mat behind the heating element conforms to the shape of the tumbler to apply even pressure.

Both of these parts fail, and the silicone mat tends to fail well before the heating element, as it’s exposed to repeated mechanical forces which break down the material over time.

HTVRONT helps mitigate this with a two-component design. The rubber wrap is separate from the heating element, so when the wrap fails, it’s easy and inexpensive to replace.

The insert is a bulky piece of kit. It contains the heating element, which is connected to the machine with a large, multi-pin header.

The insert slides onto rails on the machine and clicks securely into position. This is part of the mechanism which closes the press and applies pressure.

The large orange release button is easy to pull, disengaging the clip securing the insert.

The A200’s controls are straightforward and don’t require much documentation to understand. The display always shows the set time (60 seconds in the image below) and pressure (45 pounds), while the temperature is realtime as the unit preheats. The temperature display supports both Fahrenheit and Celsius.

Pressing the temperature, time, or pressure buttons allows using the (-) and (+) buttons to adjust the setting for each. The R button blinks red while the machine is preheating, and illuminates solid green when preheating is complete.

Pressing the R button will cause the machine to close to the set pressure, regardless of whether it’s fully preheated. Pressing the R button again releases the press, so you can easily adjust things before leaving the press to complete your project.

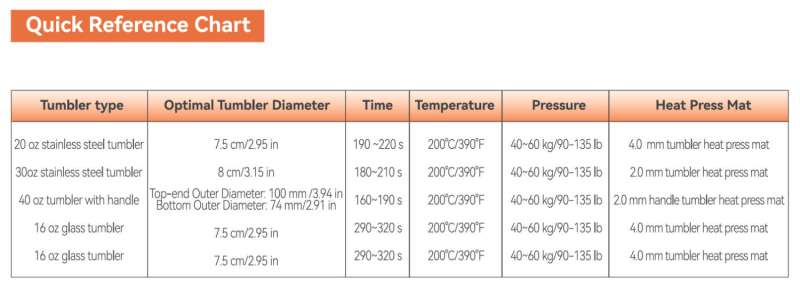

The gear button allows you to set four custom configurations for quick access. The machine includes configurations for these four slots. These four configurations use the same temperature (390F) and pressure (100 lbs.), varying on time.

- A: 20 oz. straight tumbler (195 seconds)

- B: 30 oz. straight tumbler (185 seconds)

- C: 16 oz. glass (300 seconds)

- D: 40 oz. handled tumbler (170 seconds, requires 40 oz. handled insert and wrap)

These configurations may be customized to your liking, which is handy.

What can you make with the A200?

Out of the box, the A200 can press any straight, cylindrical container 74-80mm (about 3-3.125″) diameter and no taller than 260mm (about 10.25″). This includes both double-walled stainless steel and glass tumblers.

The A200 is designed for full wrap pressing only, which means it cannot press drinkware with a non-removable handle. Extra-large 40 oz. sublimation blanks generally have removable handles, leaving only a small metal tab. The additional insert accessory (and accompanying rubber wrap) makes it easy to apply even pressure to the tapered shapes found on 40 oz. tumblers. However, with the currently available assortment of inserts and wraps, the A200 cannot properly apply pressure to tapered tumblers which don’t fit correctly in the 40 oz. wrap. This includes tapered 20 and 30 oz. tumblers readily available online. I’ve sublimated several 30 oz. tumblers, which are similar in shape to 40 oz. handled tumblers, but not quite enough! The bottom profile of these tumblers is slightly different from the larger 40 oz. model, which resulted in a bad ink transfer around the straight-sided base.

Using the HTVRONT A200

The basic steps for the A200 are similar to any other drinkware sublimation process:

Preheat the press. Start with 390F, which is what HTVRONT recommends for all types of drinkware. I think this is in part because of the material used for the rubber wraps, which is durable but insulating.

Print your design in reverse. Trim the print and tape it – very tightly – to the blank item. Also tape the full diameter of the wrap on both ends, using your thumbs to tightly fold the tape over as you turn the tumbler. Not using shrink wrap requires this extra tape, or you’ll end up with blurry, faded spots around the edges of your design.

Once the press is hot (it will beep), wear heat-resistant gloves, wrap the item with the appropriate rubber wrap, and insert the wrapped tumbler from the right side of the press, carefully ensuring the edges of the wrap are aligned and will fully close.

Press the green R button to close the press. Check to make sure the rubber wrap is aligned and fully closed on both ends. If there’s a gap, trust me – it’s worth it to press the R button to release the press and adjust the wrap so it fully closes. Any gap in the wrap will result in defects in your design.

Wait for the press to signal its completion. Wear heat-resistant gloves, and carefully remove the wrap and item from the press. The wrap will be very hot – almost 400F – so immediately set it somewhere heatproof.

This is the biggest safety warning I have for the A200. Upon completion of a tumbler, the rubber wrap is very hot. The A200 presses at 390F, meaning the outside of the wrap is around that temperature after pressing. I found out the hard way this wrap is hot enough to melt the A200’s plastic shell.

After communicating with HTVRONT about what happened, I’ve learned I’m not the only reviewer who did this. My best advice is to find somewhere very heatproof to place the hot wrap so it can cool down completely flat (so it doesn’t deform).

The larger of the two wraps (2mm) is 10×10″, and because of how hot it is immediately after pressing, I recommend looking for a shelf or rack made of stainless steel, including pastry cooling racks. Inexpensive chrome plating used on standard wire closet and pantry shelving tends to start showing defects when regularly exposed to heat above 390F, so I don’t recommend non-stainless wire shelves and racks. I don’t have the workbench space for a dedicated cooling rack, so I’ll eventually mount something behind my bench on a plywood panel. In the meantime, I’ve been using my (open) regular heat press for my hot wraps, since I know it’s heatproof.

I recommend active ventilation when using this press. Between the sublimation ink and the silicone rubber used for the wraps, there are enough chemical odors to warrant sticking a fan in an open window, at the very least.

Once your completed project is removed, you can hot remove the sublimation paper – just be careful with the hot surface of your drinkware. Both glass and stainless drinkware cool quickly thanks to a large, thin surface area, so you don’t have to be too patient!

Beyond pressing tumblers, the A200 can also be used to press neoprene tumbler and bottle carriers. I bought a pack of these months ago for a project, not realizing I had no way of pressing them! The plastic D-rings used for the strap are permanently attached to the carreir, so baking was out of the question. Amazon reviews suggested using a blank tumbler to press the neoprene, so I set about figuring out a way to accomplish this with the A200.

My solution is simple:

- Preheat the A200 to 390F, setting the timer to 200 seconds and 155 lbs. pressure.

- Wrap a blank straight tumbler with blowout or waste paper. Use the narrowest blank you have available.

- Insert the wrapped tumbler fully into a blank neoprene carrier.

- Adjust the neoprene carrier until it is as straight and tight as possible.

- Zip-tie the D-rings together and adjust the carrier’s tabs so everything is straight and properly aligned to the blank tumbler.

- Print, wrap, and tape your design.

- Once the A200 is preheated, wrap the whole thing with the 2mm universal wrap, insert, and press.

It’s important to make sure your paper wrap is really tight, or the paper might unexpectedly crease as the press closes. This happened with another wrap I made, leaving a bit of a line in the image (on the left). I was more meticulous with my wrapping and taping in my second attempt (on the right), and I used sublimation paper designed for fabric, which is only 100g. This worked really well.

Final thoughts: Is the A200 better than a sublimation oven?

I’ve been sublimating drinkware with my oven and shrink wrap for awhile now, so I’m familiar with the process – and the potential for defects.

If you’re primarily interested in producing sublimated drinkware in volume, I think a sublimation oven is a better investment – or, if you can afford it, look into vacuum sublimation equipment.

If, however, you want to make on-demand custom tumblers, this is a good press, provided you take the time to properly tape everything. Because shrink wrap is not used with this press (and is not recommended, as it can melt from direct contact with heat), your taping will make the difference in the quality of your results. Any minute air gaps between paper and tumbler will result in blurry spots, so be meticulous.

Once you dial in your process for designing, producing, and taping wraps, this is a more efficient machine for producing custom drinkware with unique designs. I really like the handled tumbler insert for large 40 oz. tapered tumblers, and I’m hoping HTVRONT releases a wrap for this insert to support the 30 oz. tapered tumblers readily available online. In the meantime, these tumblers will not sublimate very well if your design covers the straight bottom section of the base.

I really like the engineering of the A200. The use of silicone rubber wraps in tandem with separate heated inserts means the wraps, which won’t last nearly as long as the inserts, are inexpensive and easy to replace. It also means HTVRONT can (theoretically) introduce different wraps using their existing heated inserts.

I think the A200 has a whole lot of potential. I’m going to continue using my sublimation oven for ceramic mugs and when I need to produce multiple drinkware items as a batch, but I like the press for its efficiency and flexibility, and I really do like not dealing with the smell and waste of shrink wrap.

Give this a spin if you’re into making sublimated drinkware and drinkware accessories!

What I like about the HTVRONT A200 Sublimation Tumbler Auto-Press

- Faster than an oven for making on-demand custom drinkware

- Doesn’t require shrink wrap

- Silicone rubber wraps are less expensive to replace than traditional electric drinkware press heated wraps

- Excellent potential for supporting a variety of tapered tumbler profiles

What needs to be improved?

- 40 oz. tapered tumbler insert doesn’t quite properly sublimate 30 oz. tapered tumblers

- Any gaps in taping result in sublimation defects

- Exterior plastic shell isn’t fully heatproof

Price: $279.99

Where to buy: Amazon

Source: The sample for this review was provided by HTVRONT. They did not have a final say on the review and did not preview the review before it was published.

Check out these other reviews!

- HTVRONT H17 Vacuum Sublimation Machine review – Taking sublimation to the next level

- HTVRONT Manual Hat Heat Press review – Hats, hot off the press