REVIEW – If you’ve read any of my 3D printer-related reviews or news articles over the last few years, you might be familiar with my journey from 3D print enthusiast/hobbyist to running Etsy and Amazon stores as a growing side hustle. I enjoy finding, printing, finishing, and selling all sorts of fidget toys and decorative items, and the Bambu Labs printers have taken over my entire print farm. I started with a P1S printer with the original AMS (automatic material system), and then over time added A1 minis, A1s, P1Ps, and even a pair of H2D dual nozzle machines in the last few months. The H2D printers are quite expensive and have limitations on which colors can print on which spot on the bed (due to the dual nozzle system), so the opportunity to review the new single-nozzle Bambu Lab H2S 3D printer was one of the fastest “yes” replies I’ve sent in my life.

⬇︎ Jump to summary (pros/cons)

Price: $1249-2099 ($1499 AMS 2 Combo reviewed)

Where to buy: Bambu Lab

What is it?

The Bambu Lab H2S 3D printer is a FDM (Fused Deposition Modeling) printer, which takes spools of filament (various plastic materials) and creates new objects layer by layer. The H2S model is nearly identical to the previous H2D model that Bambu Labs released earlier this year, but with a single nozzle toolhead (which reduces cost and complexity). It still has the option of adding one or more AMS 2 Pro units for multi-color printing, as well as laser and physical cutters for other projects. I was sent the H2S printer + AMS 2 Pro combo so I can’t speak to the cutter options, though they could be nice if you’re space limited in your workshop or do a variety of projects that include both printing and laser/physical cutting but not enough to justify a dedicated cutter station.

What’s included?

- Bambu Lab H2s 3D printer

- Textured PEI Build Plate

- Spool holder

- Accessory box (includes tools and lubricants)

- AMS 2 Pro (with cables)

- Safety Key

Tech specs

Printing technology: Fused Deposition Modeling

Build Volume: 340*320*340 mm³

Chassis materials: Aluminum, Steel, Plastic and Glass

Physical dimensions: 492*514*626 mm³ (without AMS2)

Net Weight: 66.1 lbs/30 kg (H2S), 67.2 lbs/30.5 kg (H2S Laser Edition), 89.7 lb/40.7 kg (H2S AMS Combo), 101 lb/45.8 kg (H2S Laser Full Combo)

Hotend materials: All Metal

Extruder Gear: Hardened Steel

Nozzle: 0.4 mm Hardened Steel (supports quick change to other sizes and materials, 0.2 – 0.8 mm supported)

Build Plates supported: Textured PEI plate, Smooth PEI plate

Maximum heatbed temperature: 120 ℃ (248 °F)

Max nozzle temperature: 350 °C (662 °F)

Filament diameter: 1.75 mm

Max toolhead speed: 1000 mm/s

Max acceleration of toolhead: 20,000 mm/s

Max flow for regular flow 0.4mm hotend: 40 mm³/s(Test parameters: 250 mm round model

with a single outer wall;

Bambu Lab ABS; 280 °C printing temperature)

Max flow for optional high flow 0.4mm hotend: 65 mm³/s(Test parameters: 250 mm round model

with a single outer wall;

Bambu Lab ABS; 280 °C printing temperature)

Chamber temperature control: Active heating and ventilating cooling, max temperature 65 °C

Pre-filter grade: G3

HEPA filter grade: H12

Activated carbon type: Granulated Coconut Shell

VOC filtration: yes (“superior”)

Particulate matter filtration: supported

Closed loop cooling: Part cooling fan, hotend cooling fan, main control board fan, chamber exhaust fan, chamber heat circulation fan, auxiliary part cooling fan

Supported filaments: PLA, PETG, TPU, PVA, BVOH, ABS, ASA, PC, PA, PET, PPS;

Carbon/Glass Fiber Reinforced PLA, PETG, PA, PET, PC, ABS, ASA, PPA, PPS

Live view camera: Built-in; 1920*1080

Toolhead camera: Built-in; 1600*1200

Bird’s Eye camera: Built-in; 3264*2448(Equipped with Laser Edition)

Door sensor: yes

Filament run out sensor: yes

Filament Tangle sensor: yes

Filament odometry: yes, with AMS2

Power loss recovery: yes

Voltage: 100-120 VAC / 200 – 240 VAC / 50/60 Hz

Max power: 1170 W @ 110 V / 2050 W @ 220 V

Working temperature: 10 °C-30 °C

Touchscreen: 5-inch 720*1280 Touchscreen

Storage: Built-in 8 GB EMMC and USB Port for flash drive (not included)

Control interface: touchscreen, mobile app, PC App

Onboard Neural processing unit: 2 TOPS

Software slicer: Bambu Studio Supports third-party slicers which export standard G-code, such as Super Slicer, PrusaSlicer and Cura, but certain advanced features may not be supported.

Supported OS for Bambu Studio: MacOS, Windows, Linux

Wifi protocols: IEEE 802.11 a/b/g/n

Wifi bands: 2.4 Ghz, 5 Ghz

Design and features

The Bambu Lab H2S 3D printer is a large rectangular slab of machinery with a glass, plastic, and aluminum exterior wrapped around a solid steel chassis. There are some minor differences to the H2D model like solid plastic sides on the H2S as opposed to glass viewing window sides on the H2D, but there are far more external similarities than differences.

A large control touchscreen (which is tiltable) and a USB port (for flash drive storage) are at the top left of the device. The entire front glass panel is hinged and swings out to access the printing area. The top has a nice glass viewing window as well as the same motorized ventilation flap at the top front that the H2D has (which pops open for lower temperature material printing like PLA. Don’t put things on top of the vents, you could prevent them from opening or have said things go flying when they pop open. On the left side of the back of the machine there is the power switch and AC power input, as well as the bright red Safety Key (which kills the machine immediately if removed). The laser cutting version of the H2S includes a kill switch accessible from the front, but the on/off button has always been sufficient for me in case of 3D printer mishaps.

On the back right there are some bus cable connectors (for AMS units), as well as two spool holder locations (you can mount the included spool holder to an upper or lower position – though it’s preinstalled in the upper position which should be better for most people (the less distance between the spool and the toolhead the better). There’s also a large opening where little filament blobs will drop out of the back of the printer (often referred to as “poop”, these purge blobs are a result of any filament changes or loading/unloading). I printed a chute and bucket that uses the lower spool holder location to mount and redirect these purge blobs to the side of the machine for easy disposal. With a single nozzle, you’re going to get purge waste if you print in multiple colors (every layer that includes more than one color will require color changes, which will in turn require purging to prevent color contamination between colors).

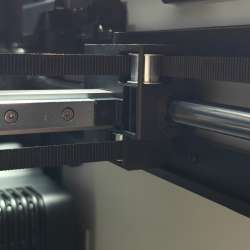

Inside the Bambu Lab H2S 3D printer is a cavernous printing area (340 mm wide x 320 mm deep x 340 mm high) unrestricted by dual-nozzle limitations found on the H2D. The toolhead includes all metal gears and heating elements, with a very handy quick change nozzle system (great for regular maintenance and even better if you switch between nozzle sizes often). The printer operates on a Core XY system, which is used to achieve very high acceleration and print speeds while maintaining excellent accuracy and minimizing errors due to machine wobble or heavy bed movements. Space is reserved for a second feed tube which may be related to the upcoming “Vortek Hotend Change System”, which will allow for multicolor printing without all the purge waste, by doing nozzle changes right inside the printer itself. Bambu Labs says this will be available as a user upgrade to both the H2D and H2S (though it will be easier on the H2S).

The AMS 2 Pro (optional as an add-on later or combo with printer) is a multiple material management system. You can load up to 4 spools of filament and even dry them out right in the AMS 2 Pro, including automatic rotation while drying to ensure even drying. When you insert a spool, the AMS 2 Pro spins it around and checks for an RFID chip – so if the spool is a Bambu Labs spool (or refill) it will read exactly what type and color of material it is, which is handy. Bambu Labs sent a variety of materials to try out including PLA, TPU (soft squishy material), PETG-CF (carbon fiber), and PLA Support filament. I also tested with PLA, ABS, and PETG spools from a variety of other manufacturers throughout the review period. You can add multiple AMS 2 Pro units, and/or the single spool AMS-HT units for a total of up to 24 different filaments/colors!

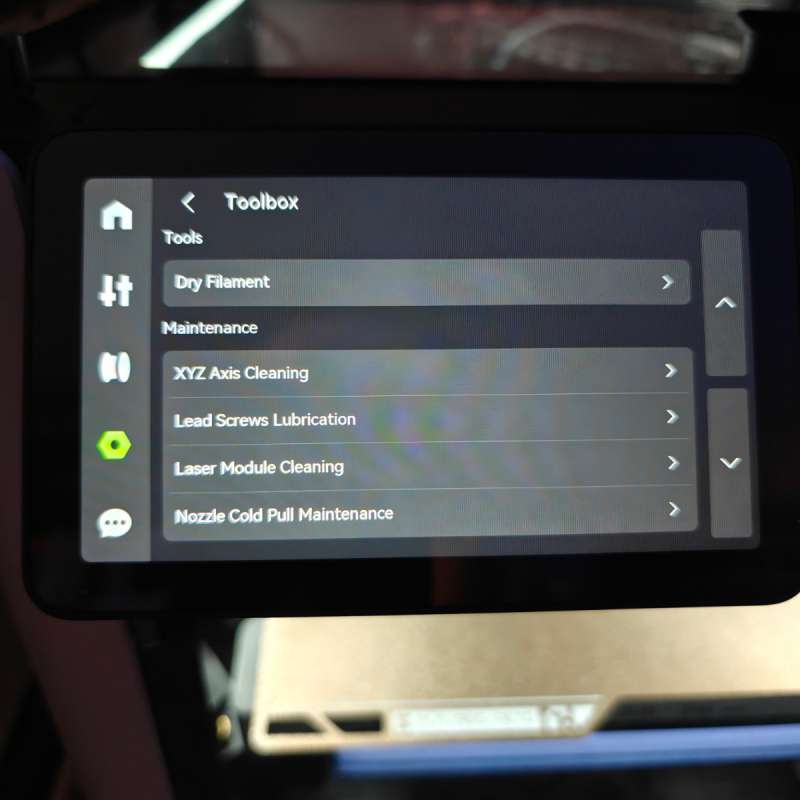

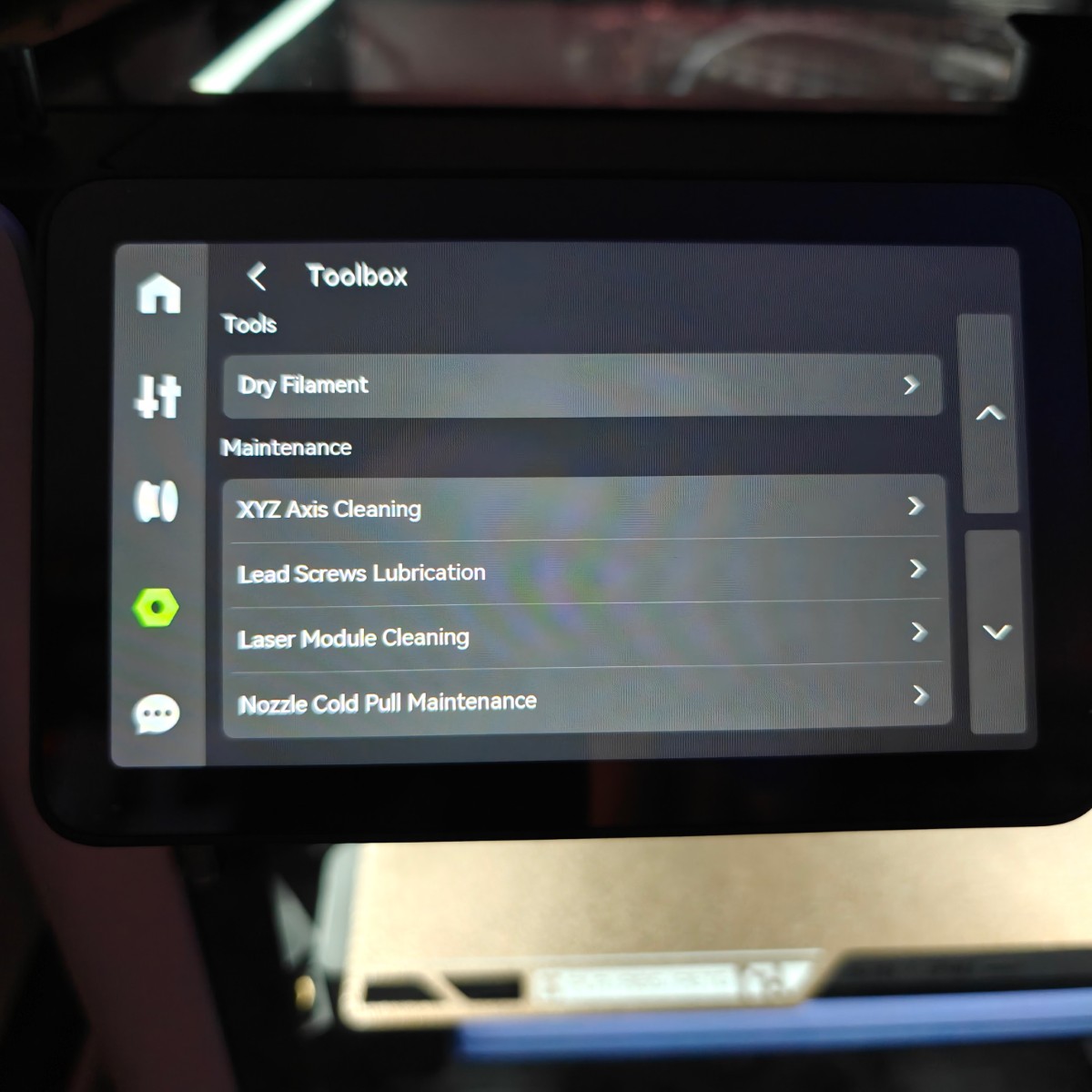

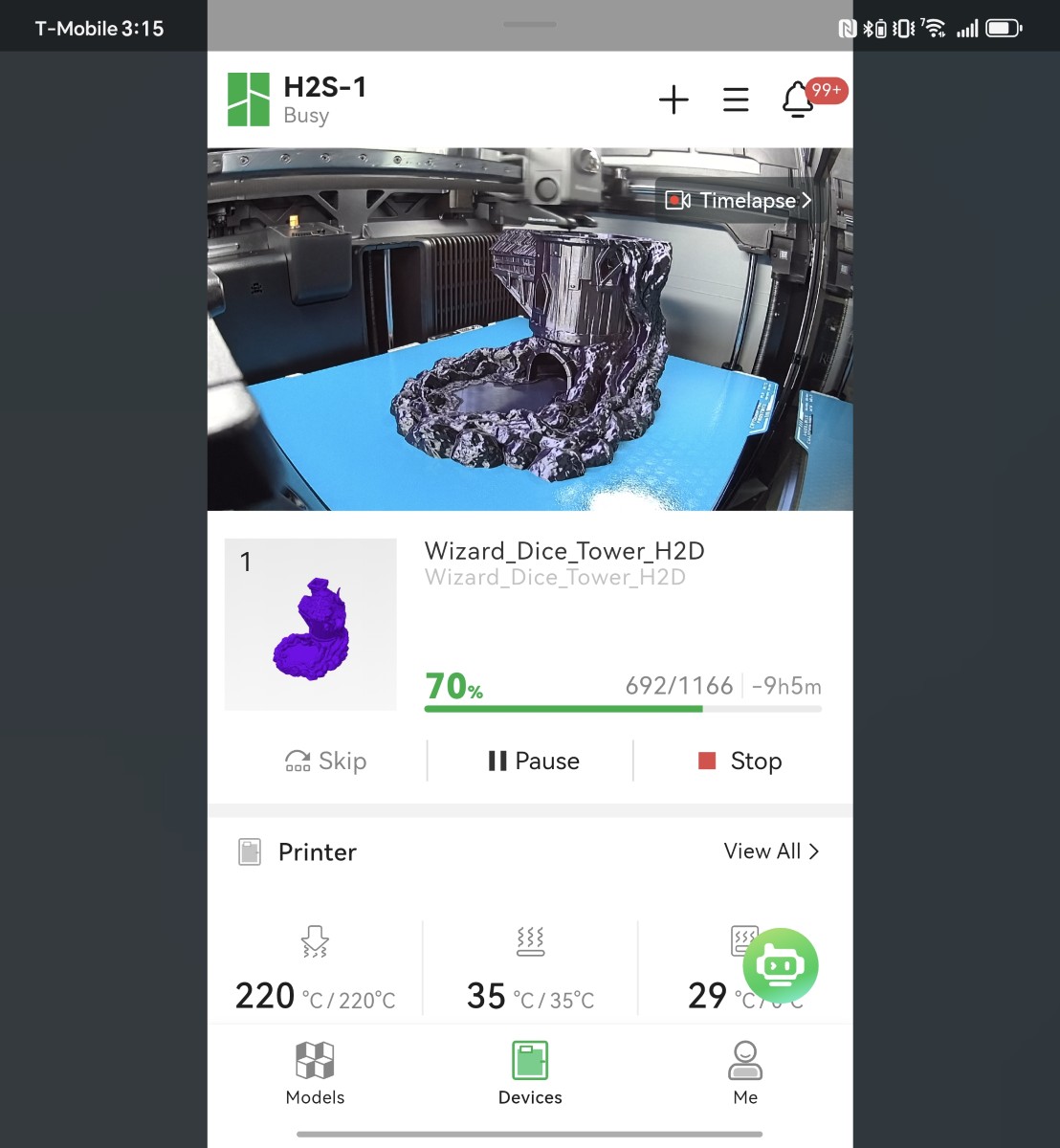

The control panel is a huge upgrade over the previous P1P/P1S models, with a highly functional menu system that is easier to navigate. I especially love the maintenance section, which simply tells me when each part should be lubricated, cleaned, or replaced (I keep a messy spreadsheet for all the older printers and often miss maintenance things). I’m also a fan of Bambu Labs PC and Mobile apps (having used nearly every other popular slicer and brand-specific slicer out there). Whether I’m looking for something fun to print as a gift, using up some old filament, or managing queues of hundreds of models for Amazon shipments, the mobile and PC software make it all so easy.

Assembly, Installation, Setup

The Bambu Lab H2S 3D printer comes very well padded and packaged, which is good because when FedEx delivered the box, it looked like they’d rolled it out of a moving truck at some point during transit. Despite extensive exterior box damage, the interior was pristine and undamaged.

If you get the AMS 2 Pro combo version like mine, the AMS unit itself is shipped screwed into place inside the printer. The assembly process involves unscrewing the AMS unit and removing shipping screws from the headbed, and removing all the tape and foam inside the printer. Bambu Labs provides easy and clear instructions to follow for this process, it’s been easy to do on every machine from them that I’ve bought so far.

Next, cables and PTFE tubes get plugged in (again, clear instructions help this process). Finally, when you turn on the machine it prompts you to do the initial calibration process which takes around 30 minutes. Once this is finished, the screen has a big QR code to scan with the Bambu Handy mobile app. Overall, the setup and assembly process remains true to Bambu Labs track record of easy and clear instructions that can be accomplished fairly quickly.

Performance

Just like the other Bambu Labs printers that I’ve been using and loving, the first Benchy (a good torture test print) came out fast and great from the Bambu Lab H2S 3D printer. That’s to be expected, though. Manufacturers typically provide a pre-sliced Benchy with ideal settings for a good first result, so the true test was to try out a variety of other prints, which I did nearly around the clock for the entire month-long test period.

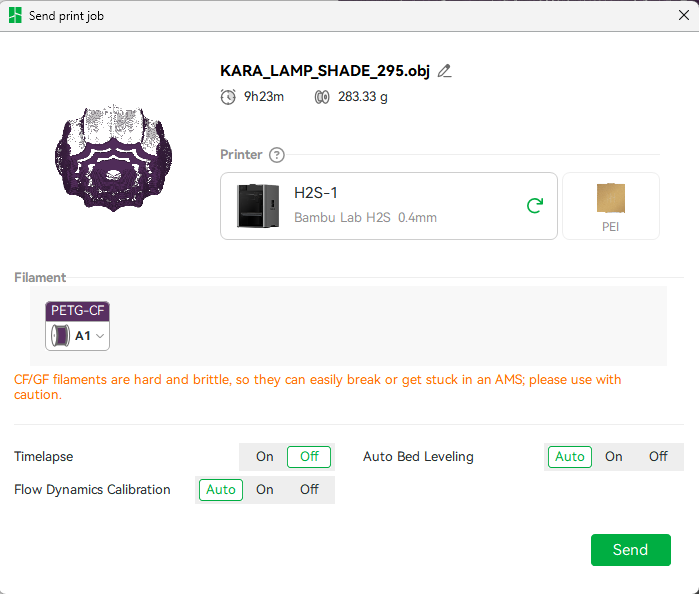

The video above shows both real-time operation of the machine as well as some timelapse videos taken by the printer itself. I tested with the filaments that I frequently use for my Etsy and Amazon products (mostly matte PLA colors and some PETG filaments for pieces that need strength). I also tested with some of the filaments that Bambu Labs sent like the PETG-CF (carbon fiber infused PETG) as well as engineering materials that I already had like ABS (which requires high heat in the chamber and on the hotend). Everything printed out great from beginning to end. I was particularly impressed with the finish on the Bambu Labs PETG-CF:

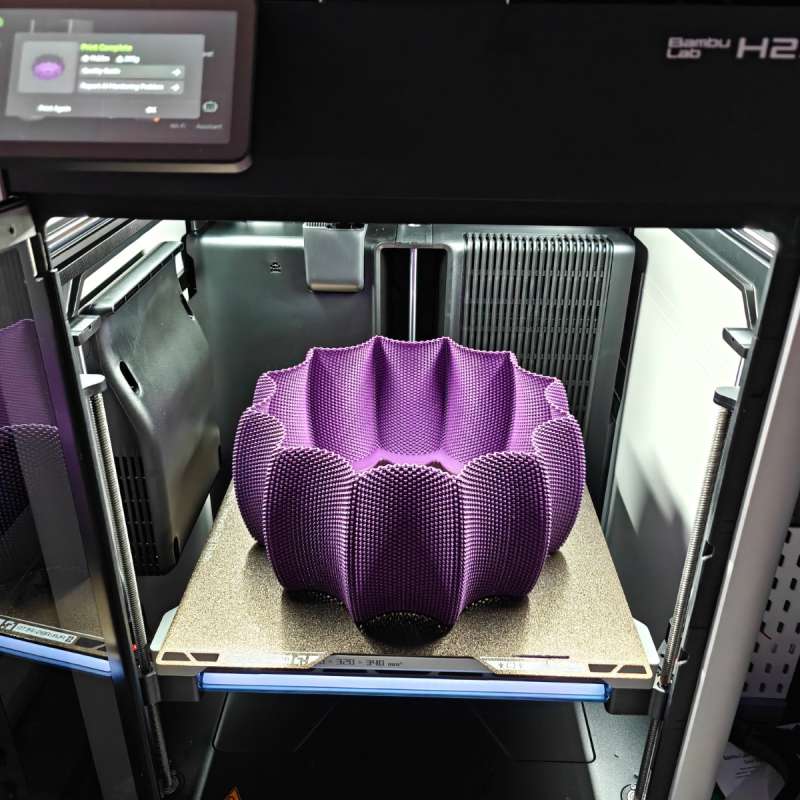

The sheer size of the print area is fantastic for anything from large batches of small objects to large things like lampshades (the photo above shows a lampshade) or cosplay items like full sized helmets.

I switched to a 0.6 mm hardened steel high-flow nozzle (the printer ships with a 0.4 mm regular flow hardened steel nozzle), and the process is identical to changing out nozzles on the A1 series of printers: you remove the silicone “sock” that covers the top of the nozzle, then unclip said nozzle, and simply pull it out and reverse the process with the new nozzle. This method is so much better than printers that require you to screw/unscrew nozzles (I’ve broken hotend assemblies before trying to apply enough torque to unscrew an old nozzle). It’s also much better than the process used in Bambu Labs P1S/P1P series printers, which requires unclipping several small cables and then removing multiple screws to get the hotend out for replacement.

Speaking of maintenance, especially as someone that runs ~10 printers at a time, I LOVE that the recent Bambu Labs printers remind you to do all required basic maintenance automatically. You get messages on screen and in the mobile app after a print job is done if maintenance is needed, and you can check status in settings on all of the tracked maintenance items:

Multicolor printing out of the box is still a wasteful process, as the printer has to purge each color of filament for each layer to prevent colors mixing during printing. This is mitigated by the ability to print a lot of copies of the same model on the large print bed, so you get less waste-per-model as opposed to smaller versions of multicolor printers. Here’s a sample multicolor item I printed on the H2S (the wind-up “legs” on the bottom were added after printing):

Final thoughts

The Bambu Lab H2S 3D printer is an excellent FDM 3D printer for anyone who needs a larger print area than the other available Bambu Labs models, and will become even more exciting when Bambu Labs releases their multiple nozzle change system (supposed to be later this year). The H2D’s that I previously purchased are just a bit harder to prepare print jobs for because there are dead zones on either edge of the build plate where one of the two nozzles can’t reach, so the H2S solves this problem by being able to utilize the entire giant print surface with the single nozzle. The AMS 2 Pro units I’ve been using for months on my H2Ds have been nearly error free (the earlier AMS units I have with my P1 series printers have needed maintenance and troubleshooting fairly frequently), and the design looks like it will make eventual maintenance easier than the first version, which is nice. With the ability to do high temperature engineering materials and the optional laser/physical cutter add-ons, the Bambu Lab H2S 3D printer is a great printer for anyone from a hobbyist to a full-time maker, especially if said making requires flexibility and variability in the projects thrown at it.

What I like about the Bambu Lab H2S 3D printer

- Large build volume without the restrictions of the H2D (dead zones for each nozzle on either side)

- Options for add-ons like a physical cutter and laser cutter/engraver

- Cheaper than the H2D while retaining most of the benefits like plate size, excellent heating/cooling features, etc.

What needs to be improved?

- Multicolor is still wasteful with a single nozzle system – though doing large batches on a big build plate mitigates this a bit

- Having the “Vision Encoder” as an optional expensive add-on is annoying, wish they could have accomplished this with the default build plate (or even had vision encoding stuff printed/etched right on the build plate mount).

Price: $1249-2099 ($1499 AMS 2 Combo reviewed)

Where to buy: Bambu Lab

Source: The sample of this product was provided for free by Bambu Lab. Bambu Lab did not have a final say on the review and did not preview the review before it was published.

Check out these other 3D printer reviews!

- Anycubic Kobra S1 3D Printer combo review – punching above its price point

- PioCreat HALOT-X1 Resin 3D Printer, Auto Feed Unit resin management system, and Creality Washing/Curing Machine review

- Bambu Lab X1 Carbon 3D printer review – Bigger really is better!

Gadgeteer Comment Policy - Please read before commenting

If by better you mean now you get to breathe more VOCs and UFPs. And everyone has shown the print quality is quite a bit worse than the P1S.

Print quality is markedly better than my P1S with the same files and filaments, but that could be due to the 7000+ hours on my P1S, unfortunately I don’t have a brand new one to compare against. I will say, the automatic flow detection on the A1/H-series printers is very nice compared to manual calibration required on the P- series. I know some people never have problems, but I’ve had quite a few prints with various issues when I skip calibration, and having to calibrate every filament (and sometimes even different colors from the same filament line) is an extra step that sucks up time.

For the VOC/UFPs, I have all of my printers vented to the outside, highly recommend that for any home user!